Waistband end processing device

A technology for processing equipment and belts, applied in clothing belts, metal processing, and other manufacturing equipment/tools, etc., can solve the problems of low processing efficiency, inconvenient belt production, and difficulty in inserting buckle B, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

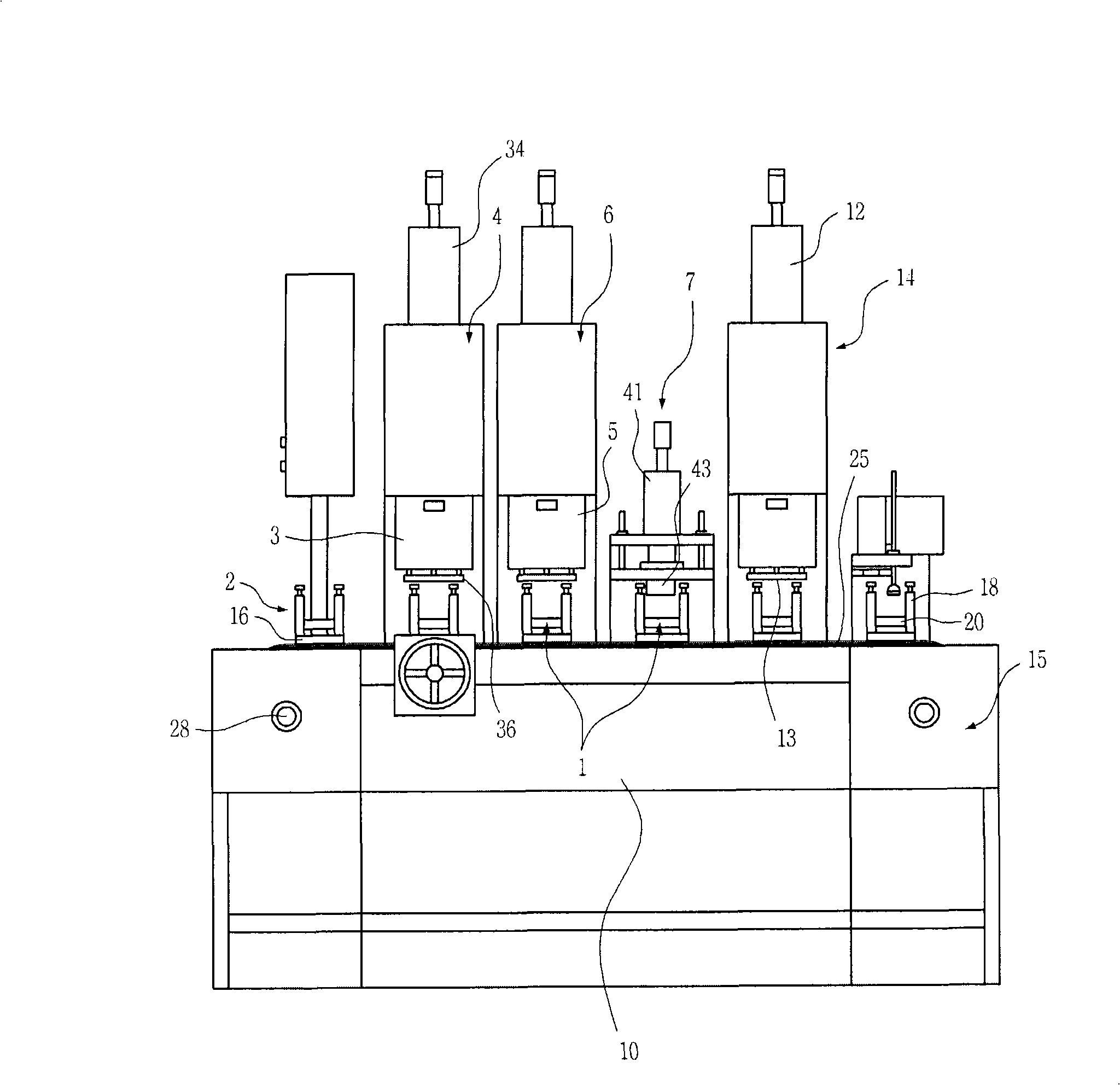

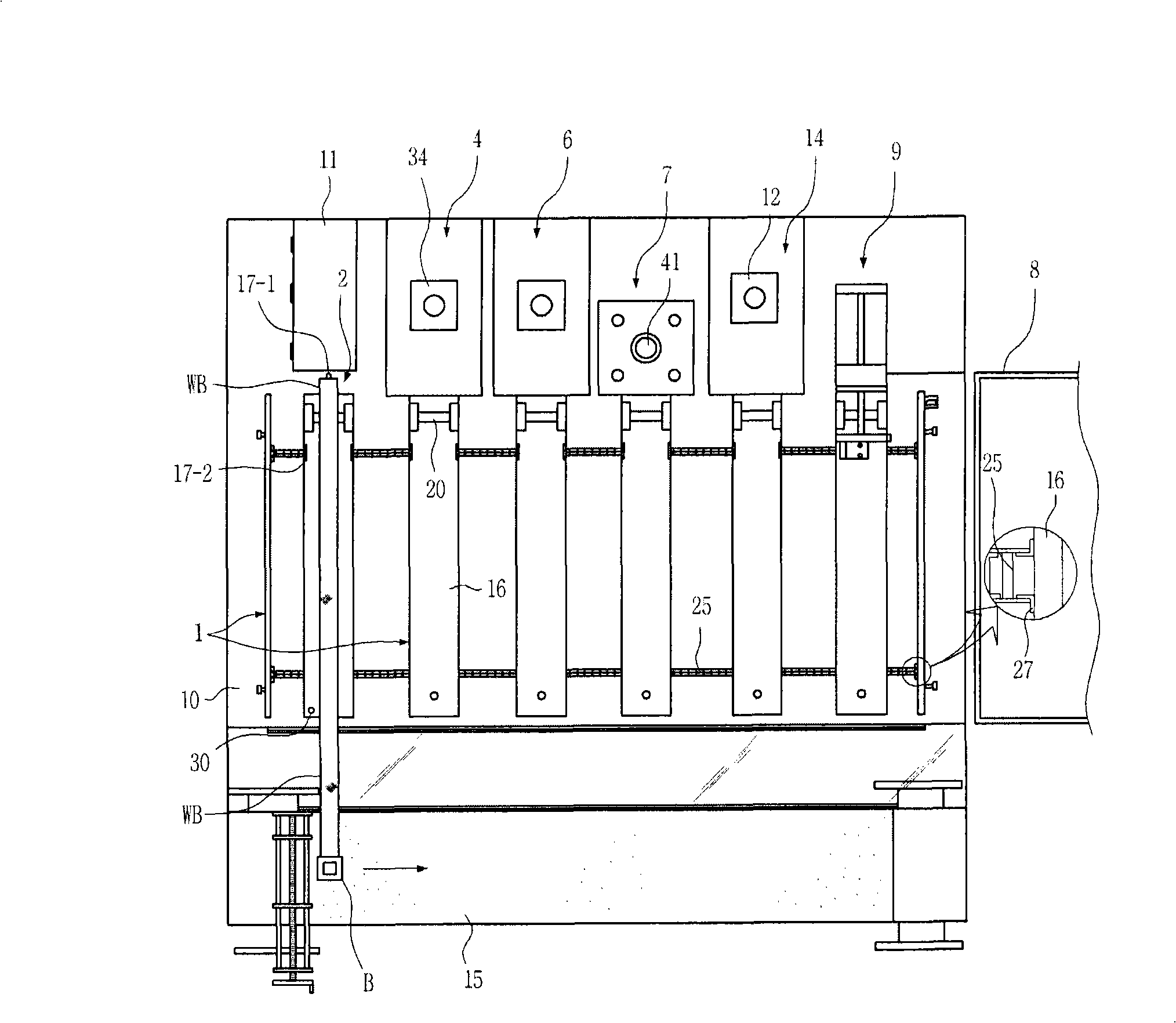

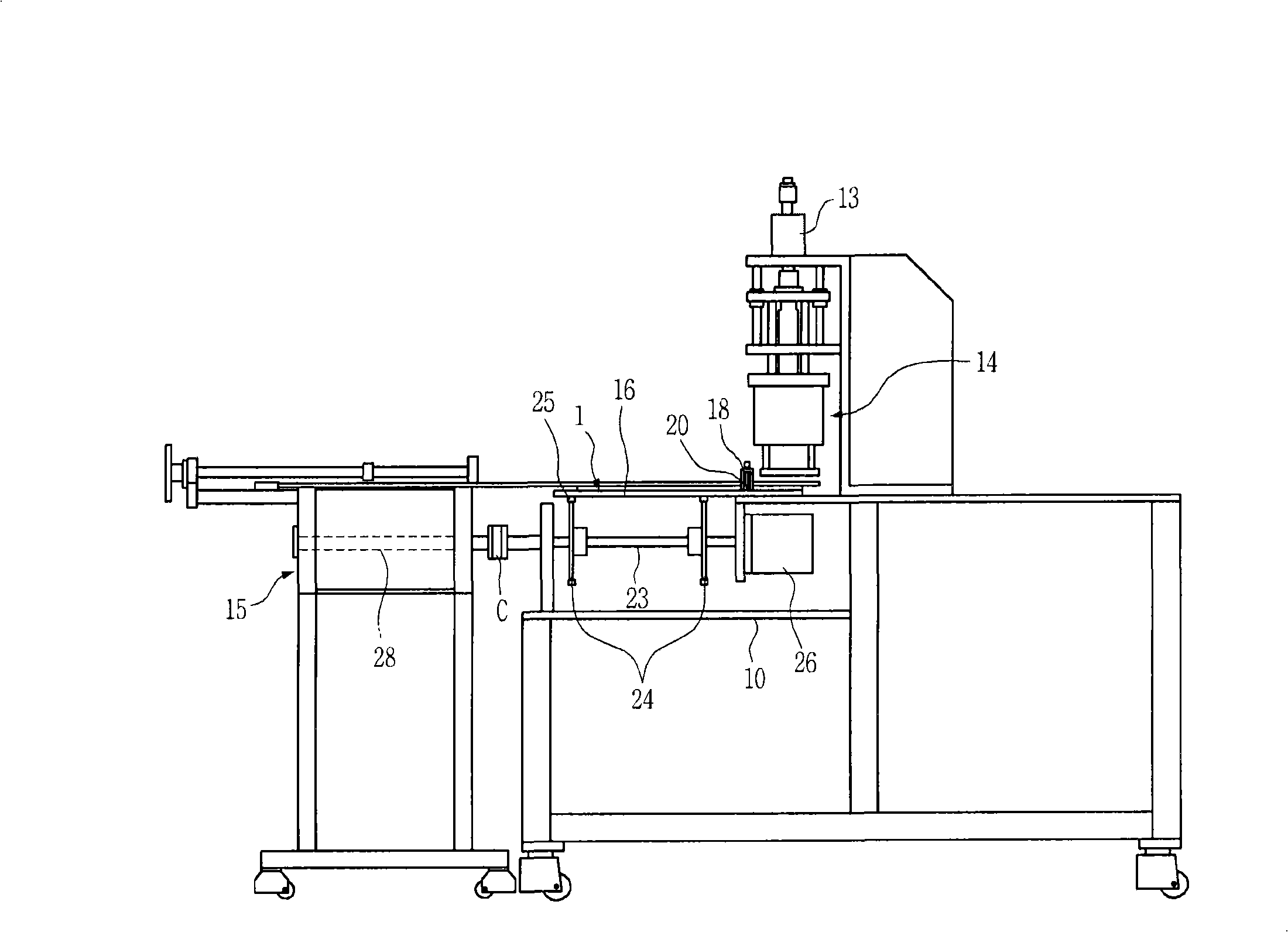

[0022] Figure 1 to Figure 3 They are respectively the front view, plan view and side view of the preferred embodiment of the belt end processing equipment involved in the present invention. As shown in the figure, the basic composition of the belt end processing equipment of the present invention includes: a transmission part that transmits the belt in a step-by-step manner; cutting parts 4 and 6 that cut the belt ends into a certain shape; The welded part 7 is thermally welded to the cut end of the belt conveyed in a step-by-step manner. The belt end processing equipment of the present invention can automatically complete operations such as conveying the belt in a step-by-step manner, cutting the end of the belt into a certain shape, and performing heat welding on the cut part according to the sequence of procedures. As shown in the drawings, a preferred embodiment of the waistband end processing apparatus of the present invention may include a printing part 14 for printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com