Method of preparing metallic lithium by one-step fusion electrolysis of lithium salt

A technology of molten electrolysis and metal lithium, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems that the application cost cannot be gradually reduced, the production process is easy to mix impurities, and metal lithium cannot be produced, so as to avoid auxiliary equipment and its influence , Improve production efficiency and metal lithium quality, save the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

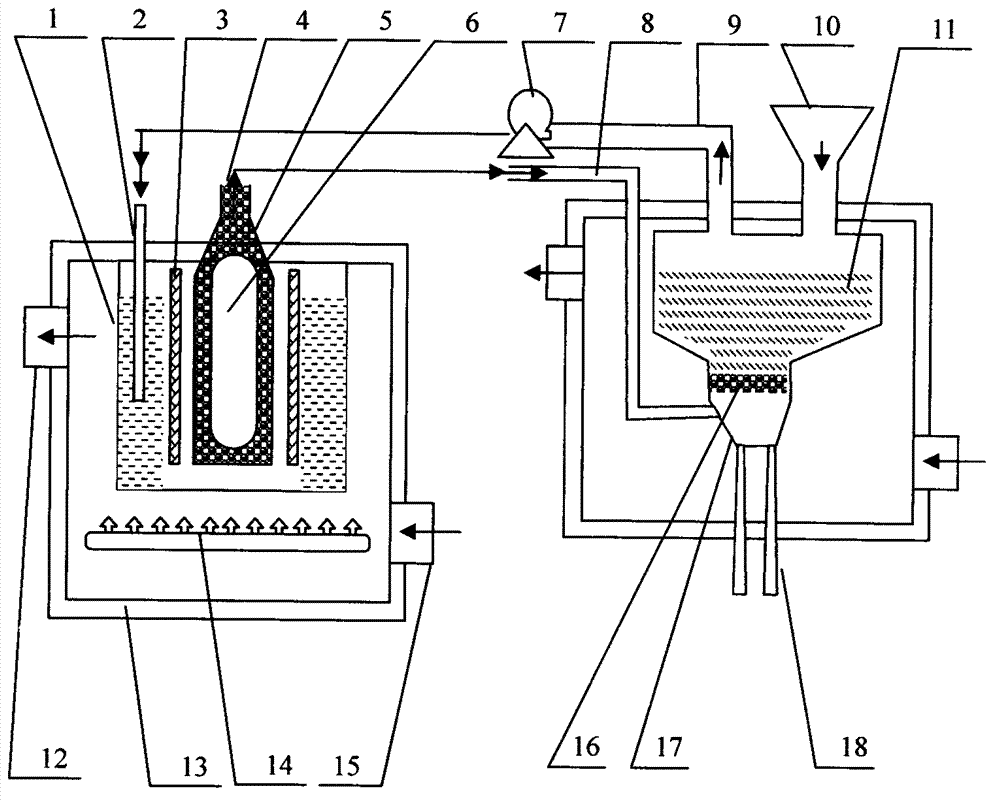

[0019] The present invention includes reaction pool 13 , decomposition chamber 1 , high temperature melting chamber 11 , iron cathode 3 , graphite anode 6 , chlorine gas return pipe 8 and circulating air return pipe 9 . Further description will be given below in conjunction with the accompanying drawings and embodiments.

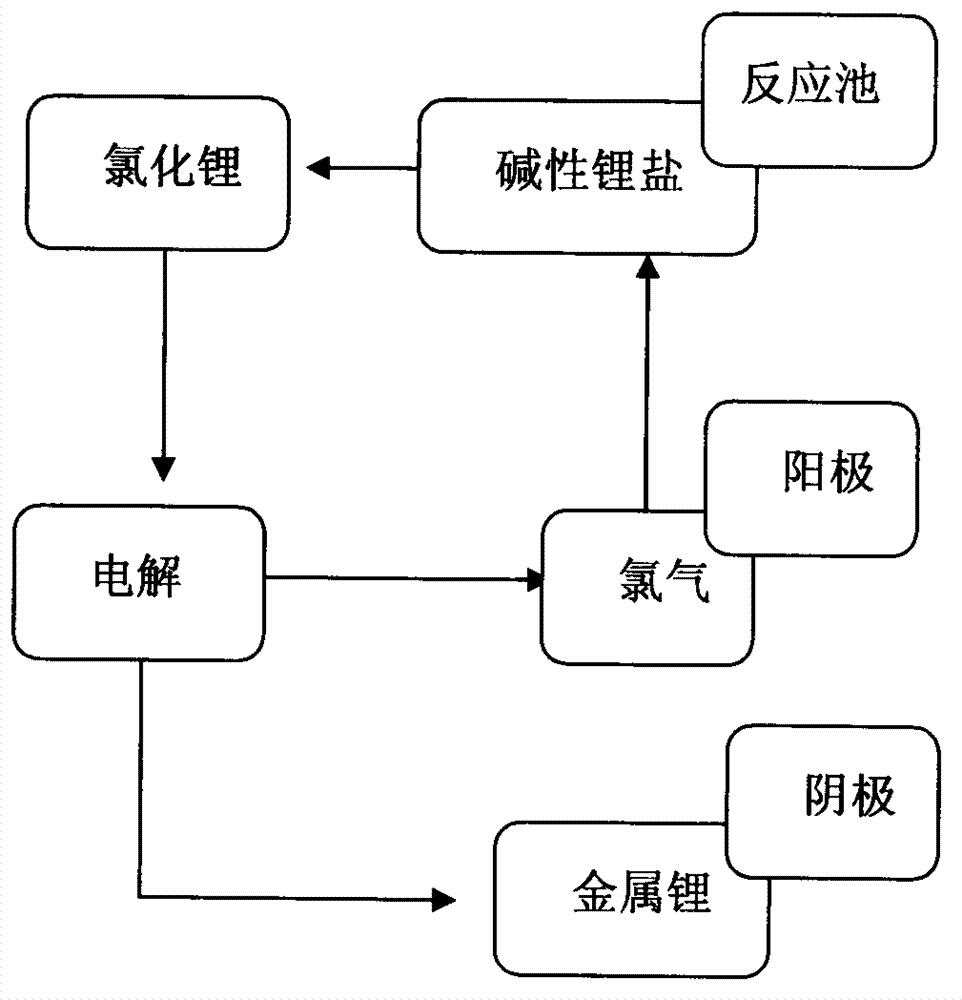

[0020] In the present invention, as attached figure 1 As shown, the chlorine gas produced by the graphite anode 6 in the electrolytic cell is pumped to the high-temperature melting chamber 11 of the decomposition cell on the reaction pool 13 through the chlorine gas return pipe 8, passes through the porous titanium sieve plate 16 from bottom to top, and is mixed with the molten alkaline lithium The salt reacts to generate lithium chloride to continue electrolysis, and lithium metal is continuously generated at the cathode from bottom to top due to the rapid reaction.

[0021] In the present invention, as attached figure 2 As shown, an electrolytic cell is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com