Method of making organic light emitting devices

a light-emitting device and organic technology, applied in the direction of solid-state devices, semiconductor devices, thermoelectric devices, etc., can solve the problems of difficult to achieve continuous and coalesced film coverage, difficult to manufacture multi-layered devices containing organic materials, and inability to heat light-emitting materials used in oleds, etc., to achieve enhanced structural integrity and enhance structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

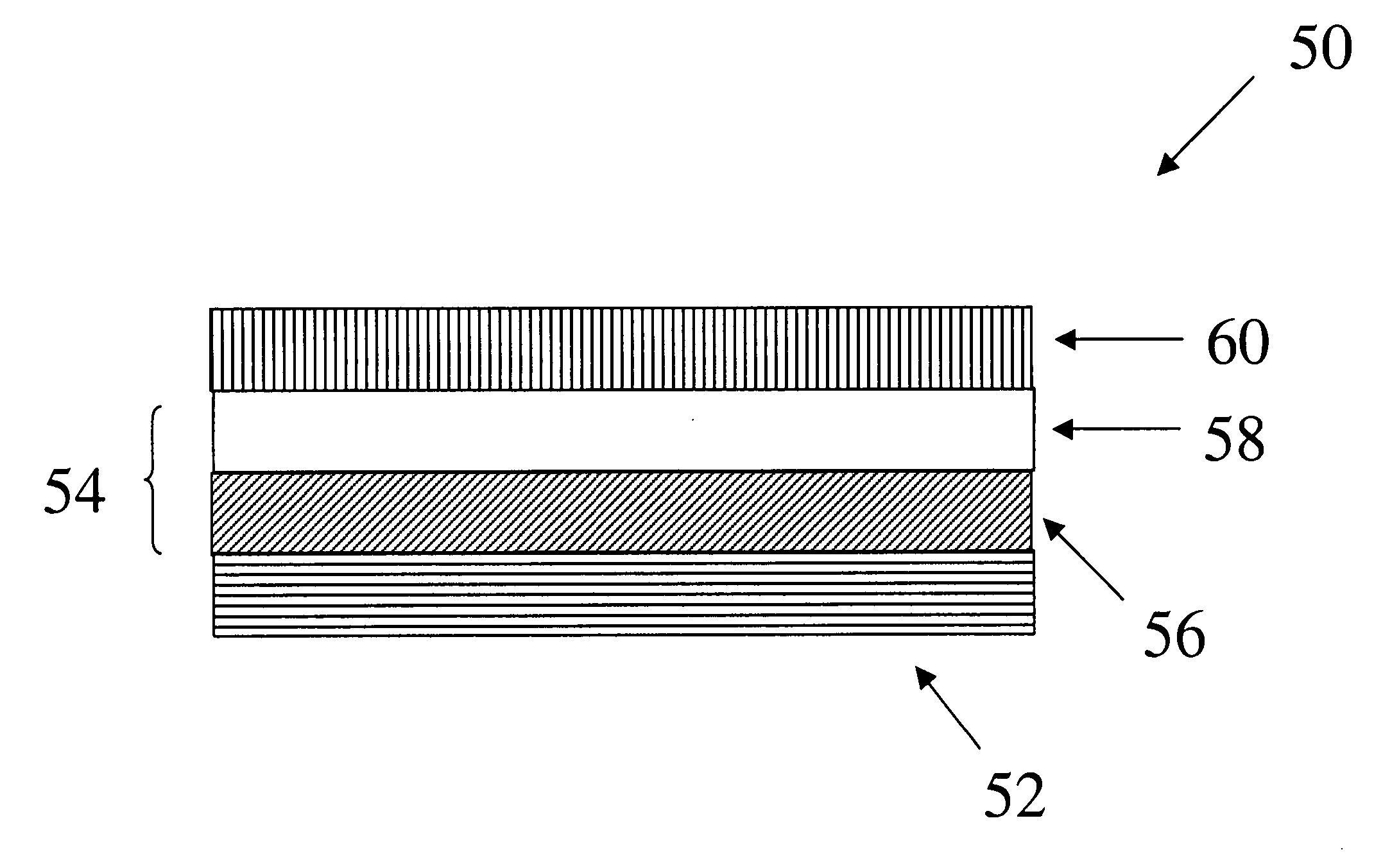

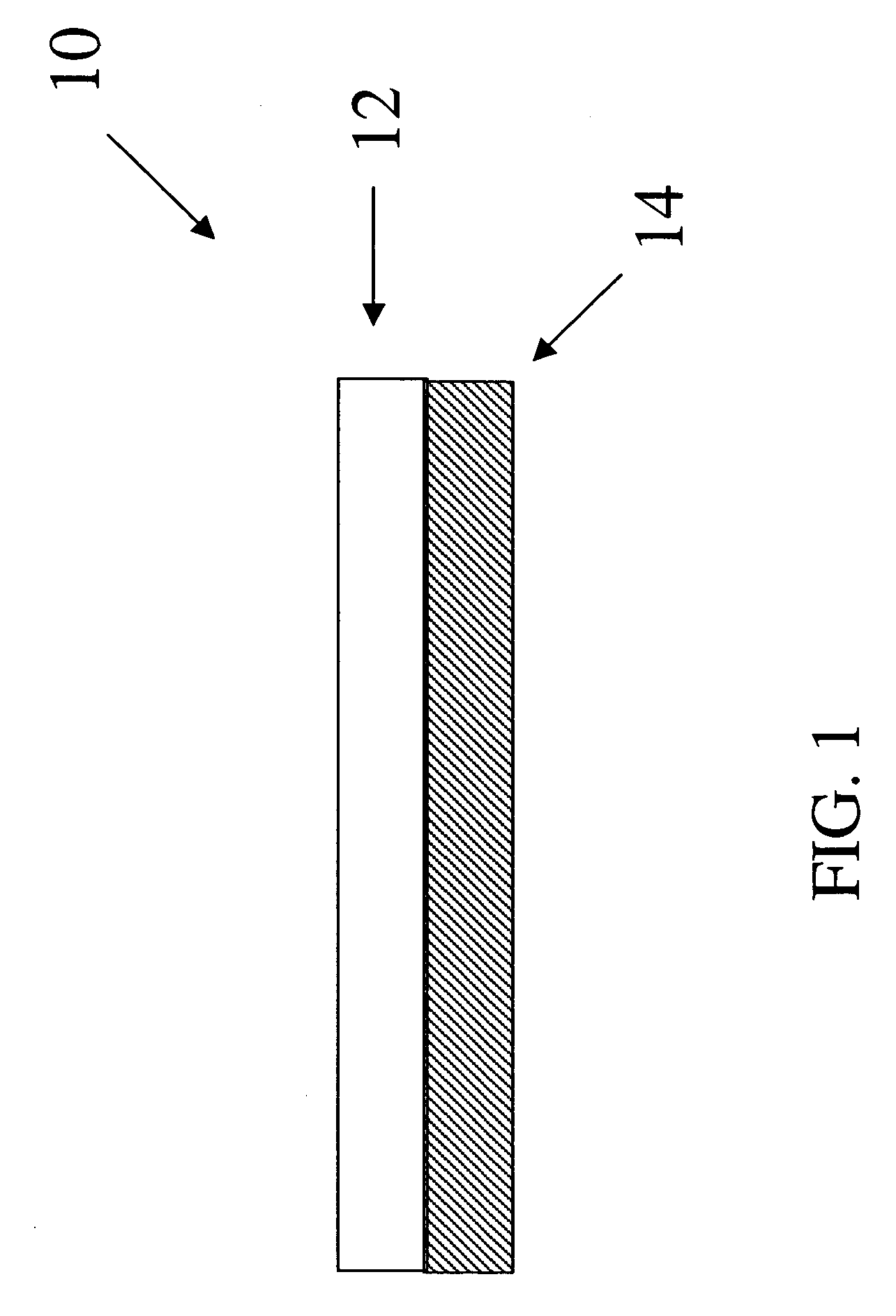

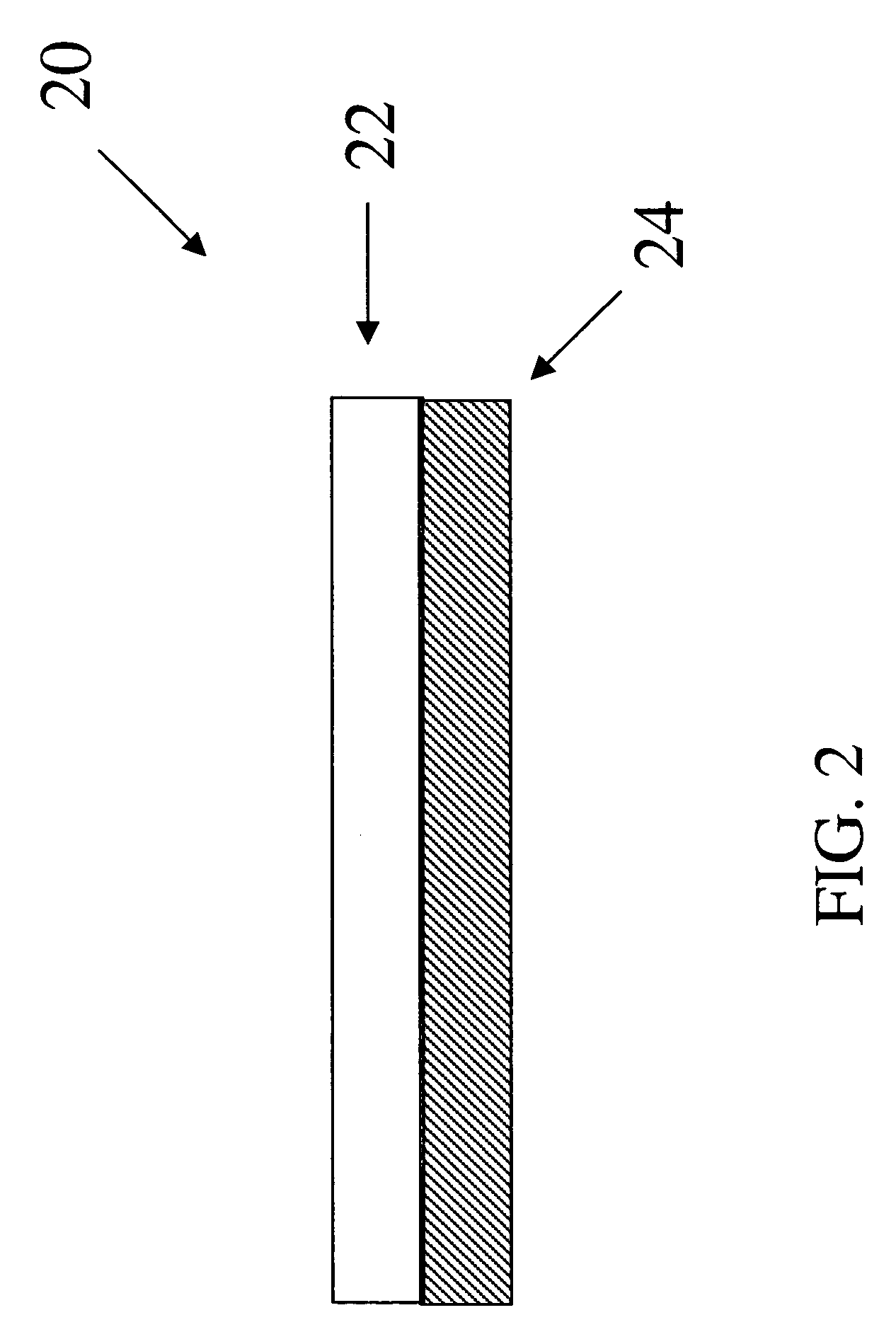

Image

Examples

example 1

Preparation of an OLED Substructure Comprising an Irradiated Cross-Linked TFB Layer Using the Photoacid Generator-1

[0078] Following the fabrication of a PEDOT coated quartz substrate (See FABRICATION), a solution of TFB and photoacid generator-1 in para-xylene was spin-coated onto the PEDOT coated quartz substrate. The thickness of the TFB film was approximately 300 angstroms and was coated by spin-coating at about 3000 rpm. The solution of TFB and photoacid generator-1 in para-xylene was prepared by heating a mixture of TFB and photoacid generator-1 in para-xylene for 60 minutes at 80 degrees Celsius while stirring. The solution comprised about 1 percent by weight TFB. The photoacid generator-1 was present in an amount corresponding to about approximately 30 weight percent of the weight of the TFB. The solution was allowed to cool down for a period of about 20 minutes prior to spin-coating. Following spin-coating, the bilayer structure comprising the layer containing TFB and photo...

example 2

Preparation of an OLED Substructure Comprising an Irradiated Cross-Linked TFB Layer Using the Photoacid Generator-2

[0079] Following the fabrication of a PEDOT coated quartz substrate; a solution of a blend of TFB and photoacid generator-2 in para-xylene was spin-coated onto the PEDOT coated quartz substrate. The thickness of the resultant TFB film was approximately 300 angstroms and was coated by spin-coating at about 3000 rpm. The solution of TFB and photoacid generator-2 in para-xylene was prepared as in Example 1. Following spin-coating, the bilayer structure comprising the layer containing TFB and photoacid generator-2, and the PEDOT layer was exposed to a UV lamp in the hood for a time period of about 5 minutes. Hereinafter, the resulting OLED substructure is referred to as Sample 6.

[0080] MEASUREMENT OF OPTICAL DENSITY: Samples 1-6 were subjected to multiple rinses in p-xylene as follows. The sample (e.g. Sample 1) was placed on top of the spinner and the surface was flooded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com