Support for cage and bottle style intermediate bulk container

a technology of intermediate bulk containers and cages, applied in the field of containers, can solve the problems of cross-contamination of shipped or stored materials, difficult to adequately clean bottles, and high cost of replacement bottles, and achieve the effect of improving the structural integrity of cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

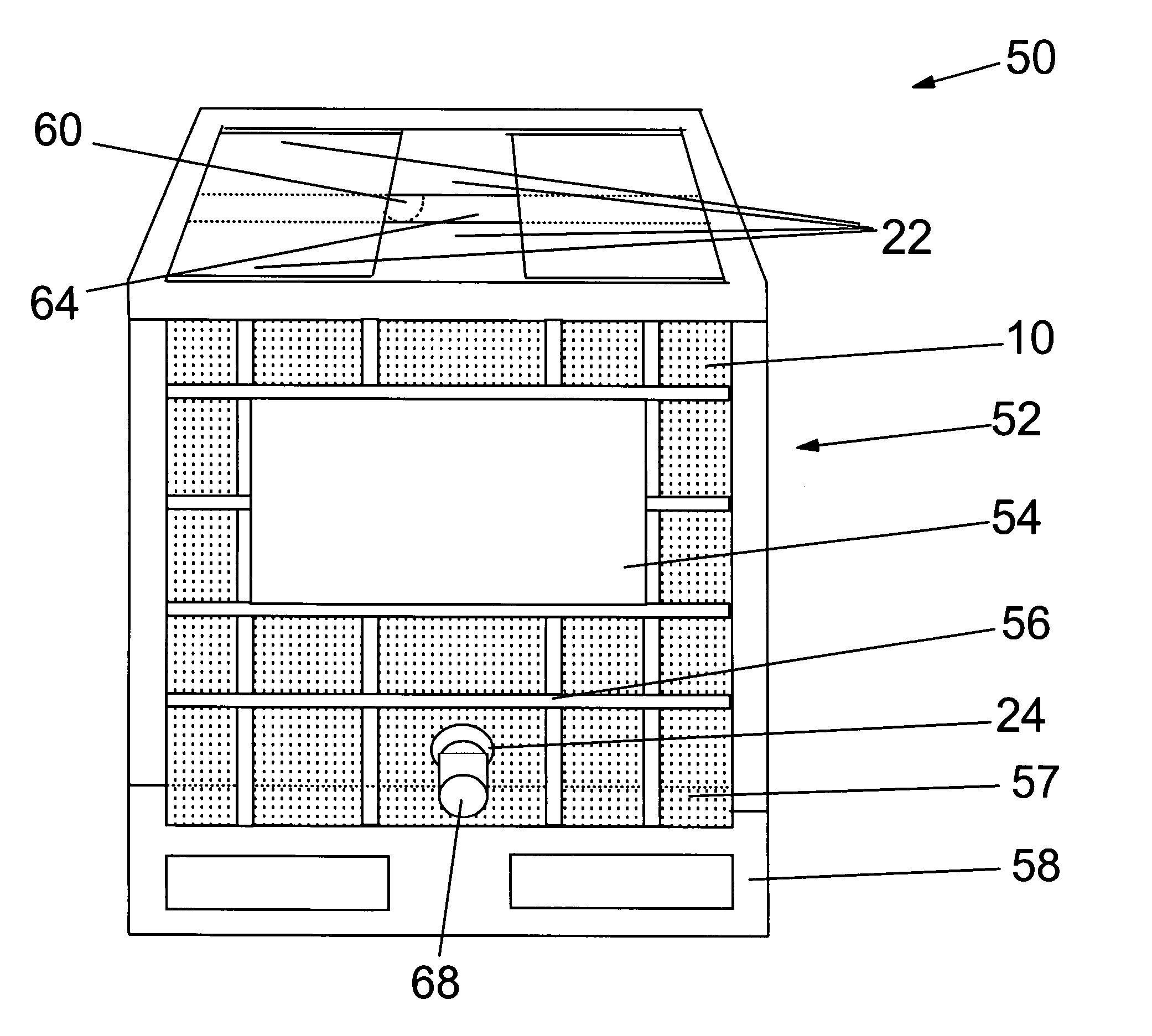

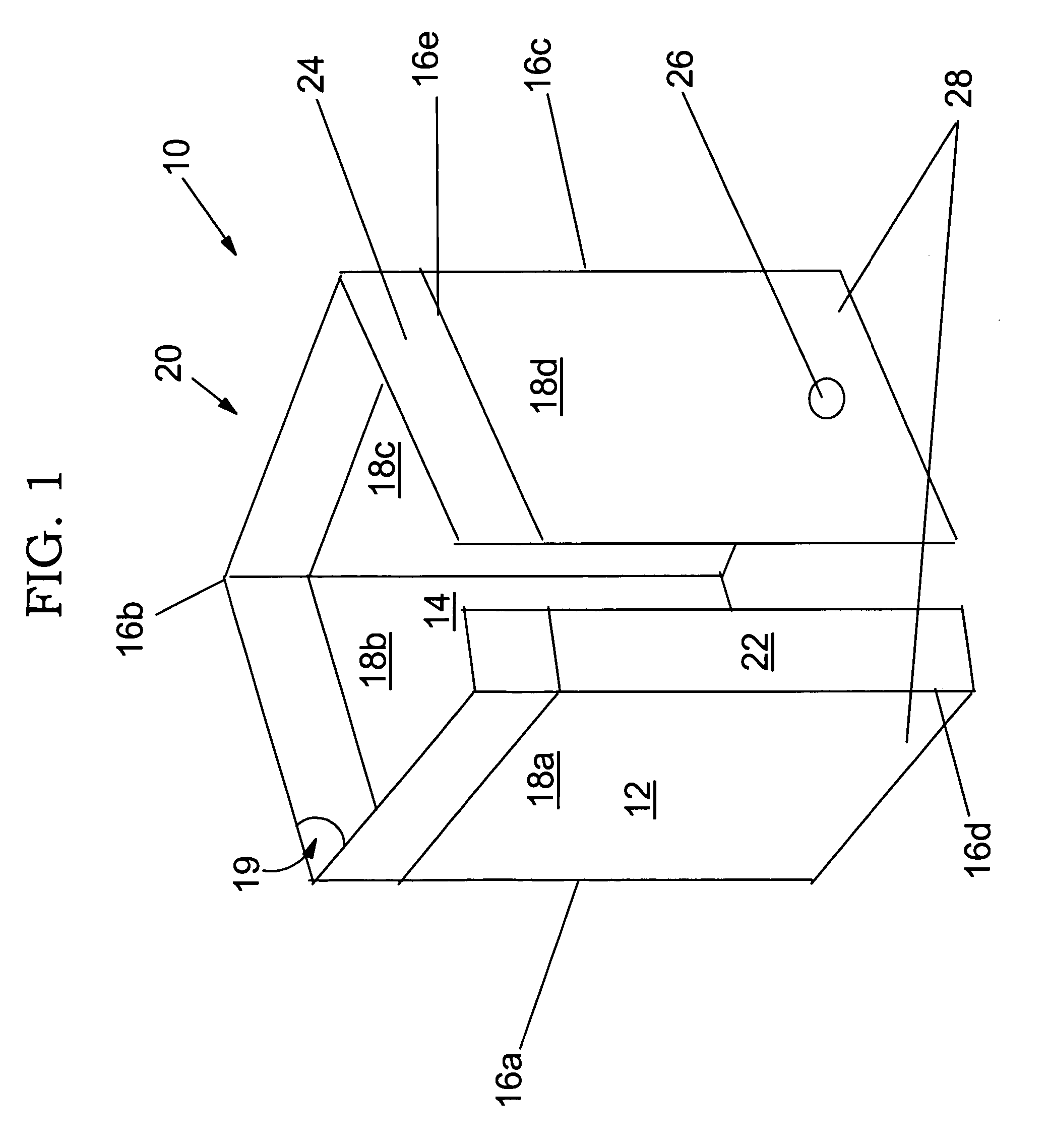

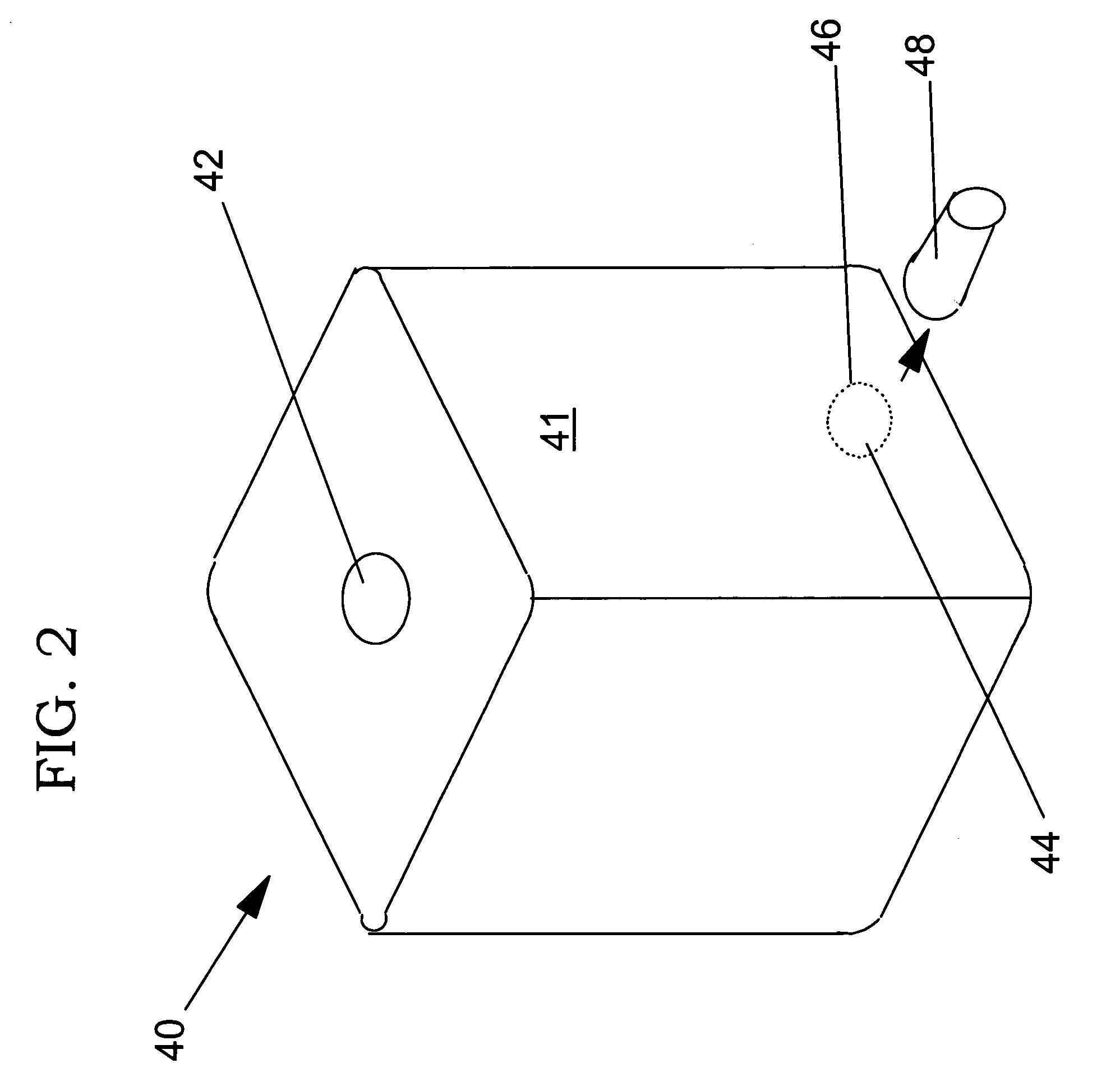

[0022] The present invention provides a system and method for using a liner in conjunction with the cage of a bottle and cage type IBC. The invention involves use of a support that is placed inside the cage of a bottle and cage type IBC. In one embodiment, the support may be a thin sheet of material, such as a sheet of hard plastic, that conforms to the inner surface of the cage. In an alternative embodiment, the support may be a bottle from a cage and bottle type IBC that has been modified by removing the discharge valve spout. In the case that a liner is used in conjunction with the cage, the support forms a barrier between the liner and the cage to prevent the liner from extruding through the bars of the cage. The support may overlap at its ends to add stability and / or to ensure that a barrier is formed with respect to the entire inner surface of the cage. The support may also have at least one top flap to improve the structural integrity of the cage and / or to form a cover for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com