Patents

Literature

40 results about "Homogeneous microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High purity tantalum, products containing the same, and methods of making the same

InactiveUS6348113B1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingMetallic materialsUltimate tensile strength

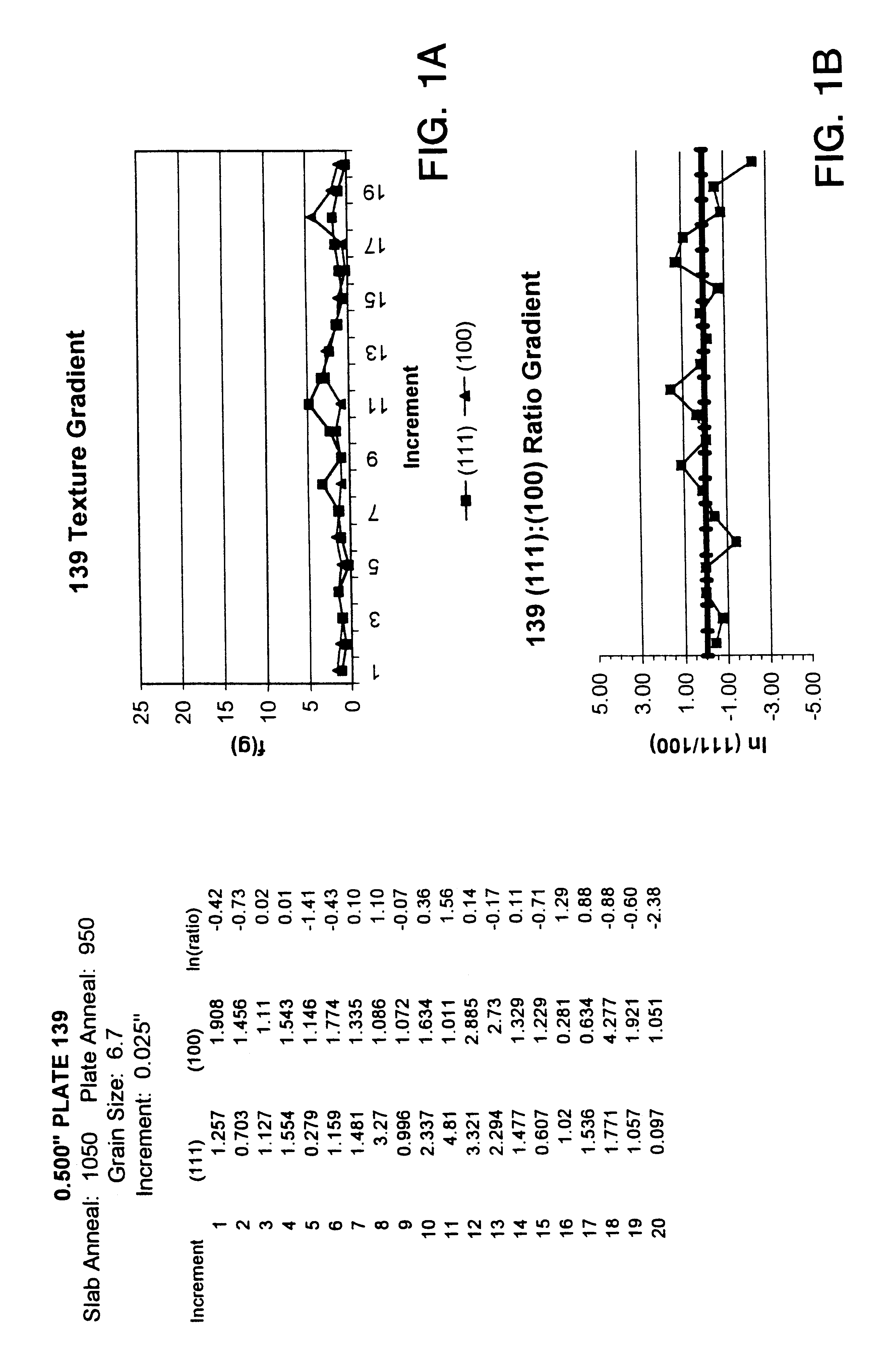

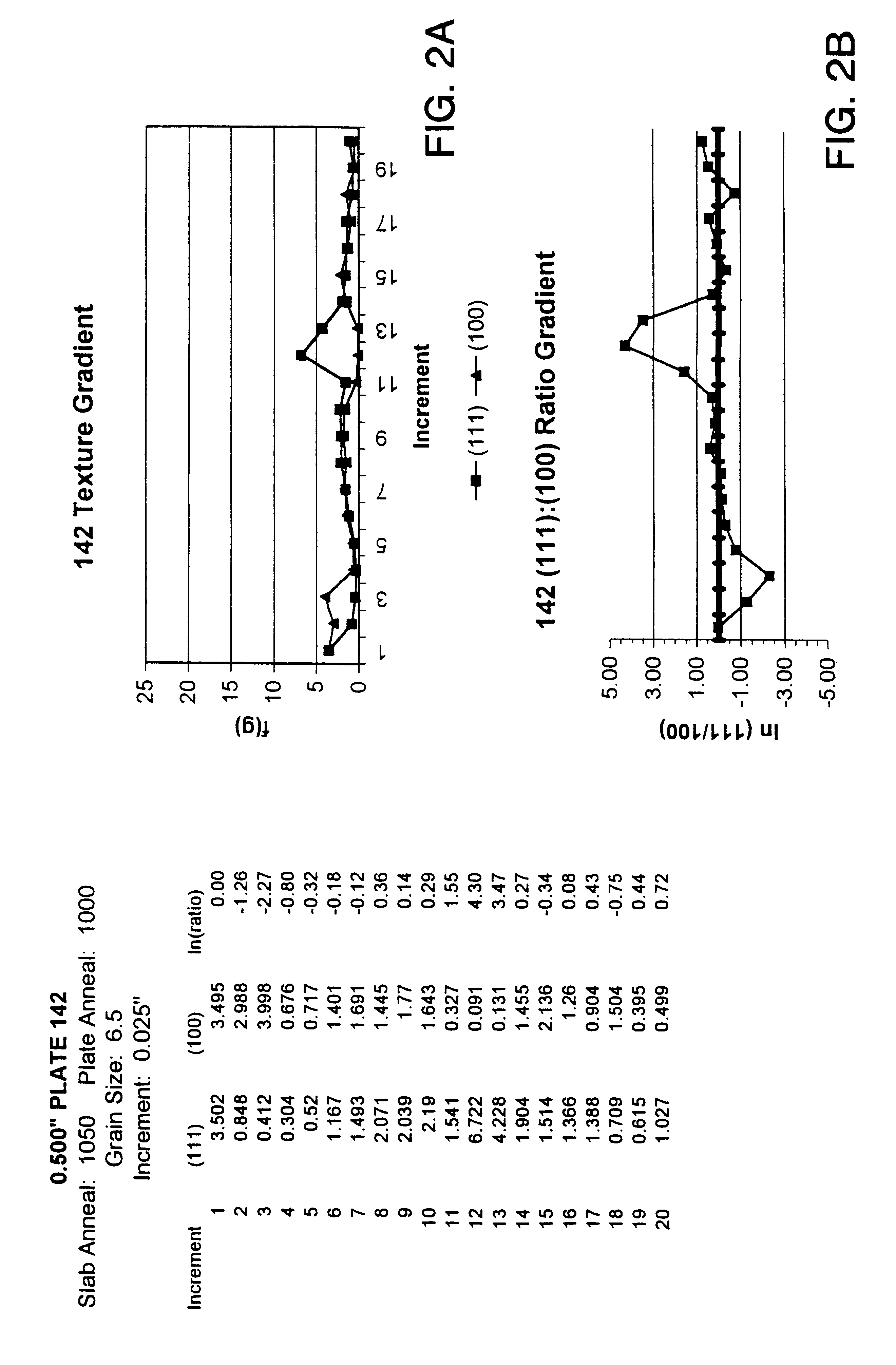

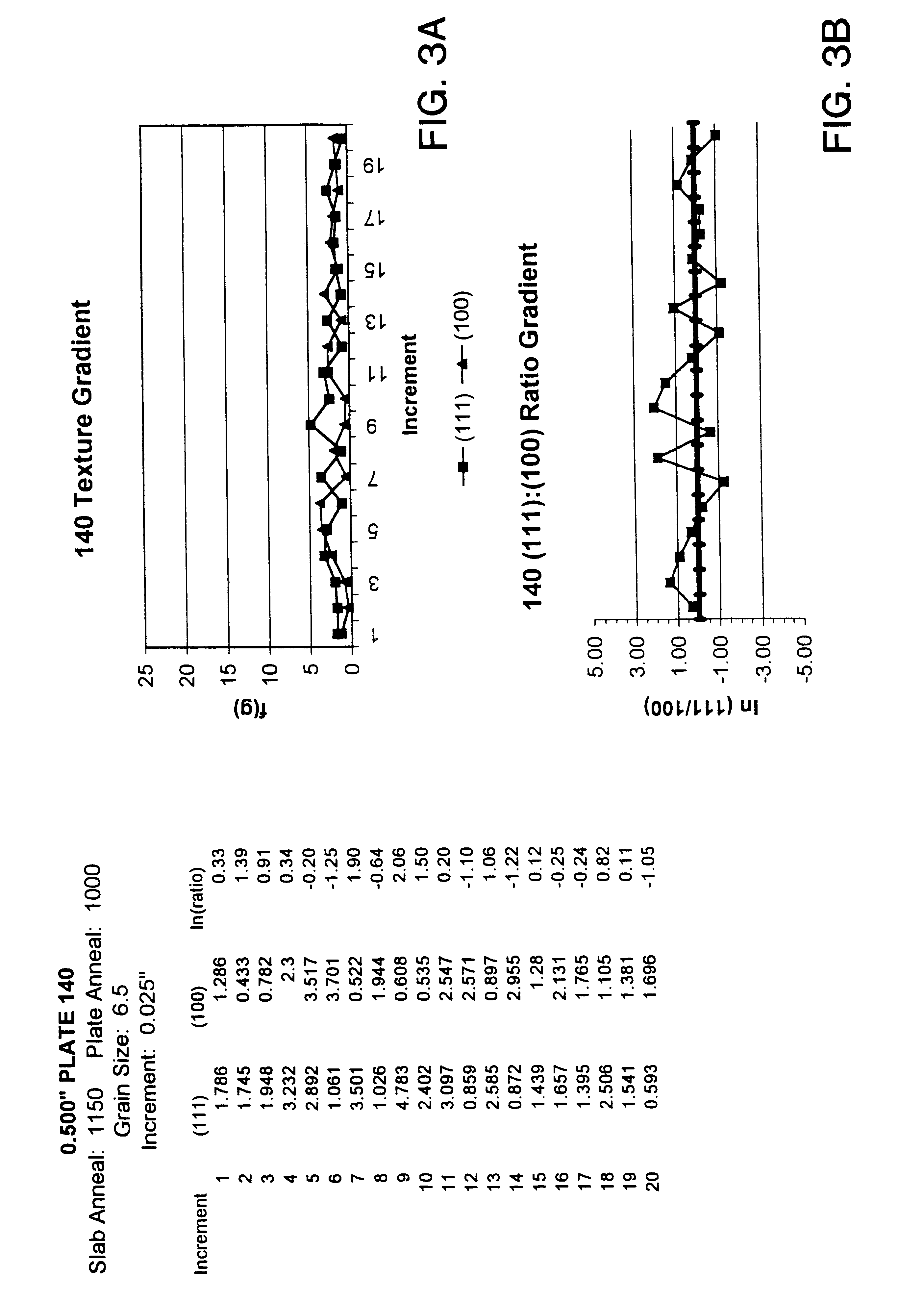

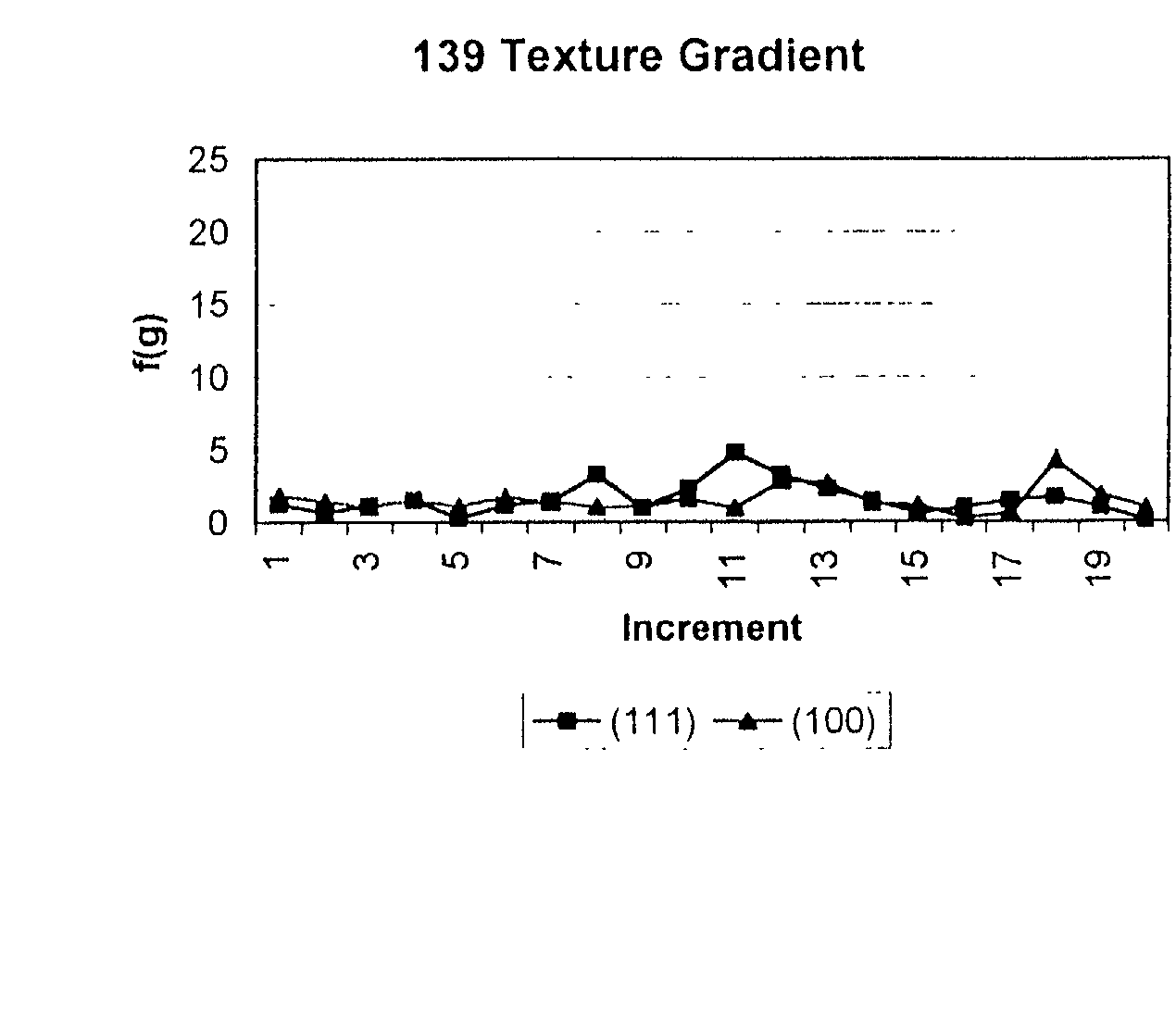

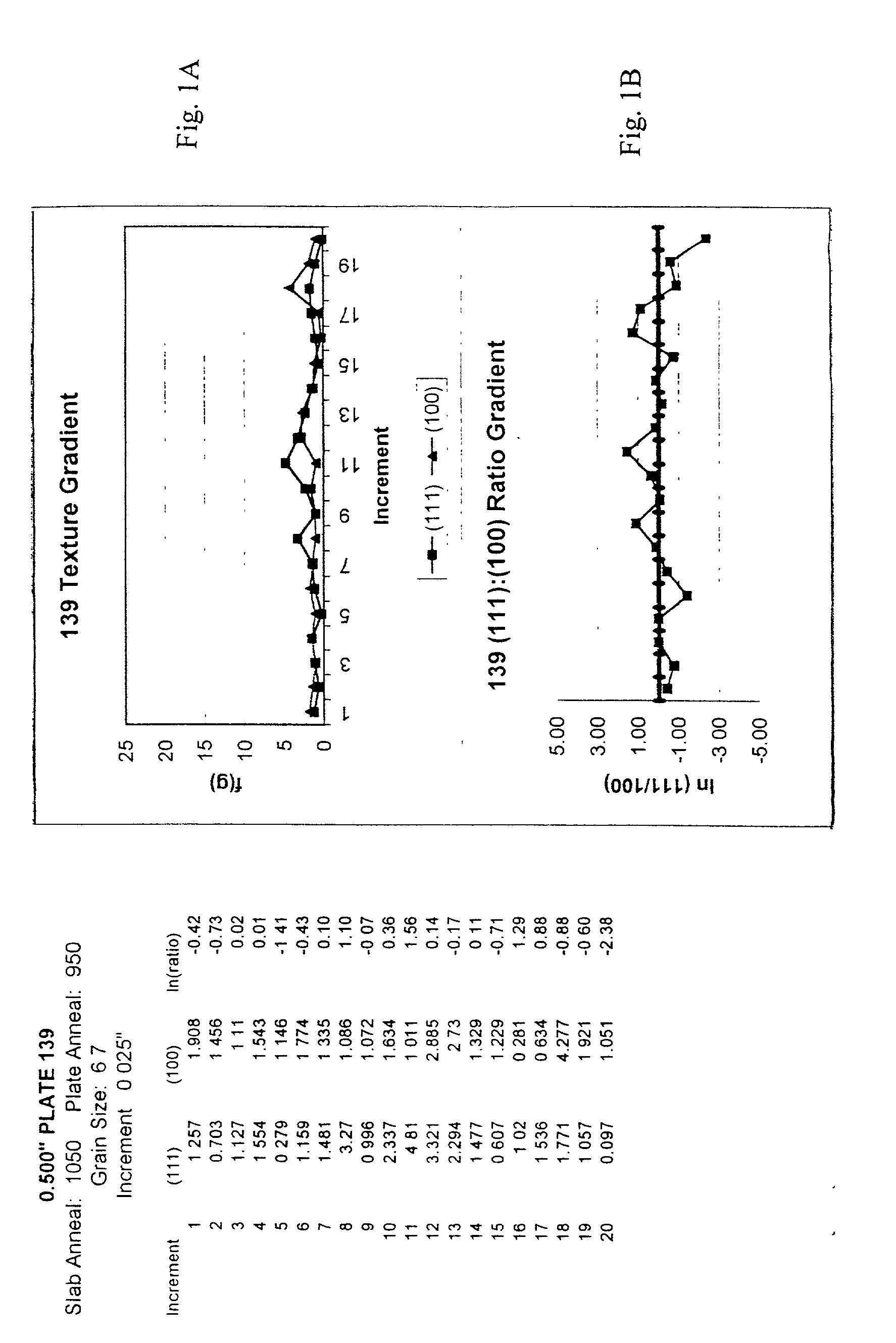

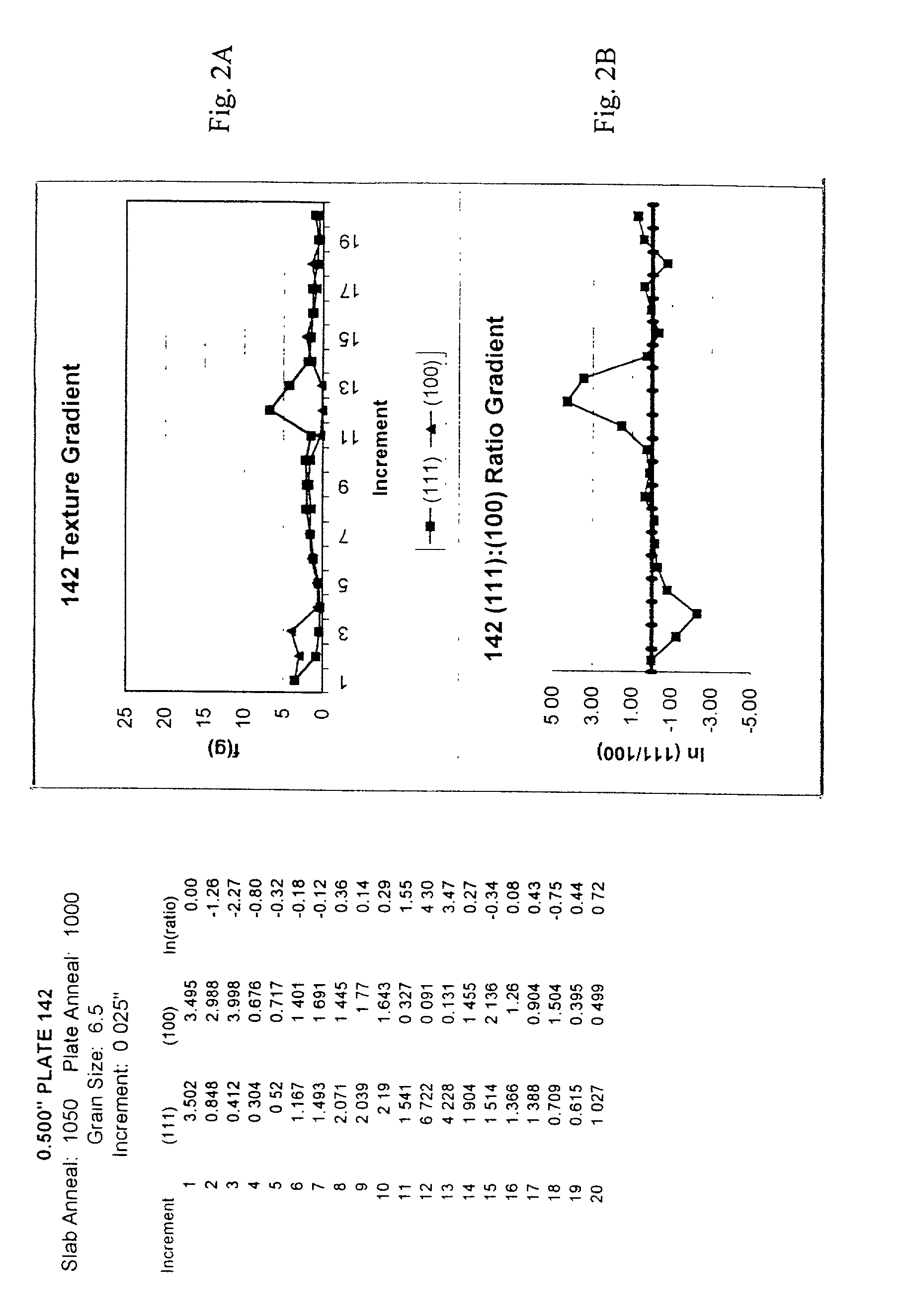

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995% and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

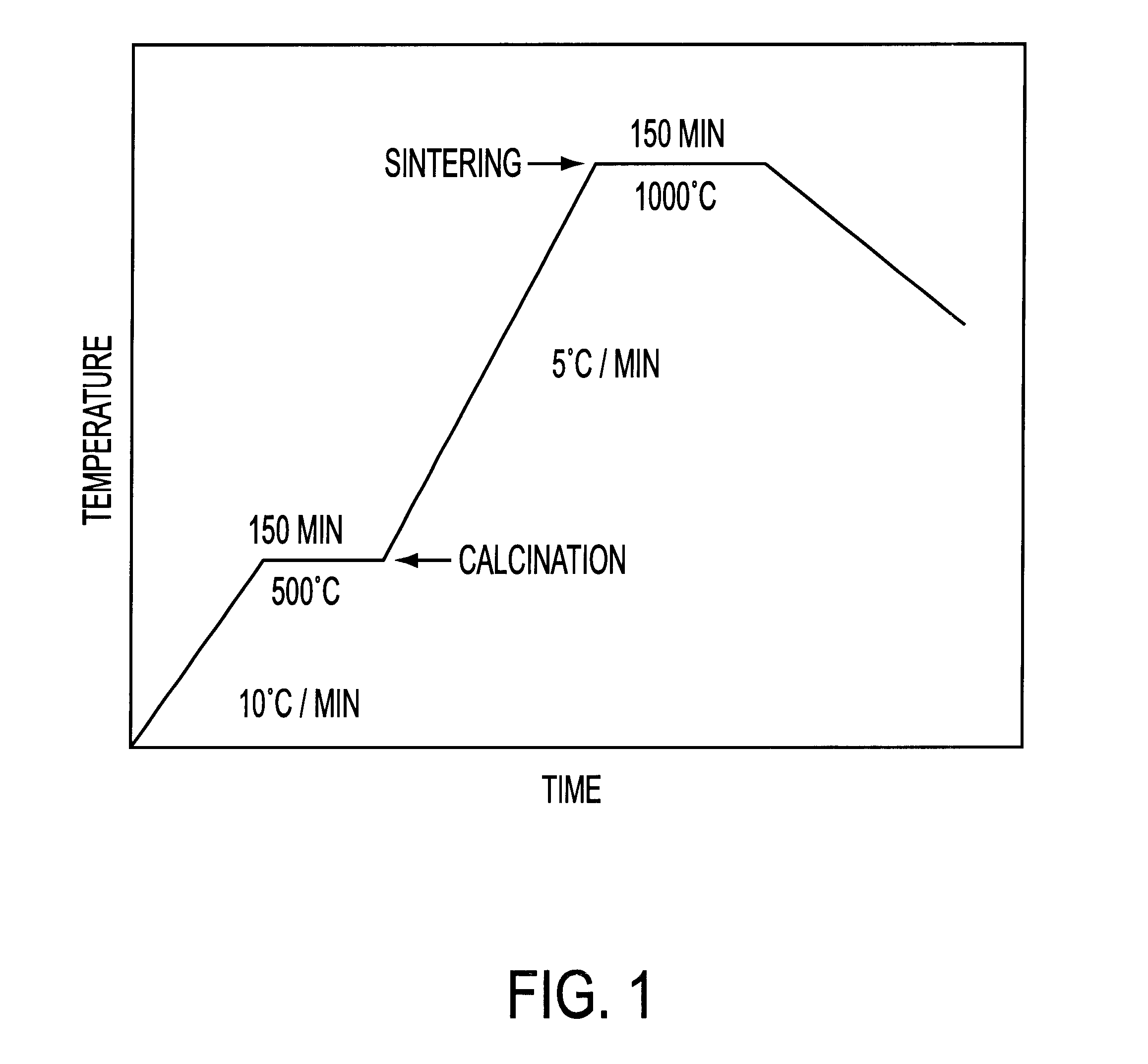

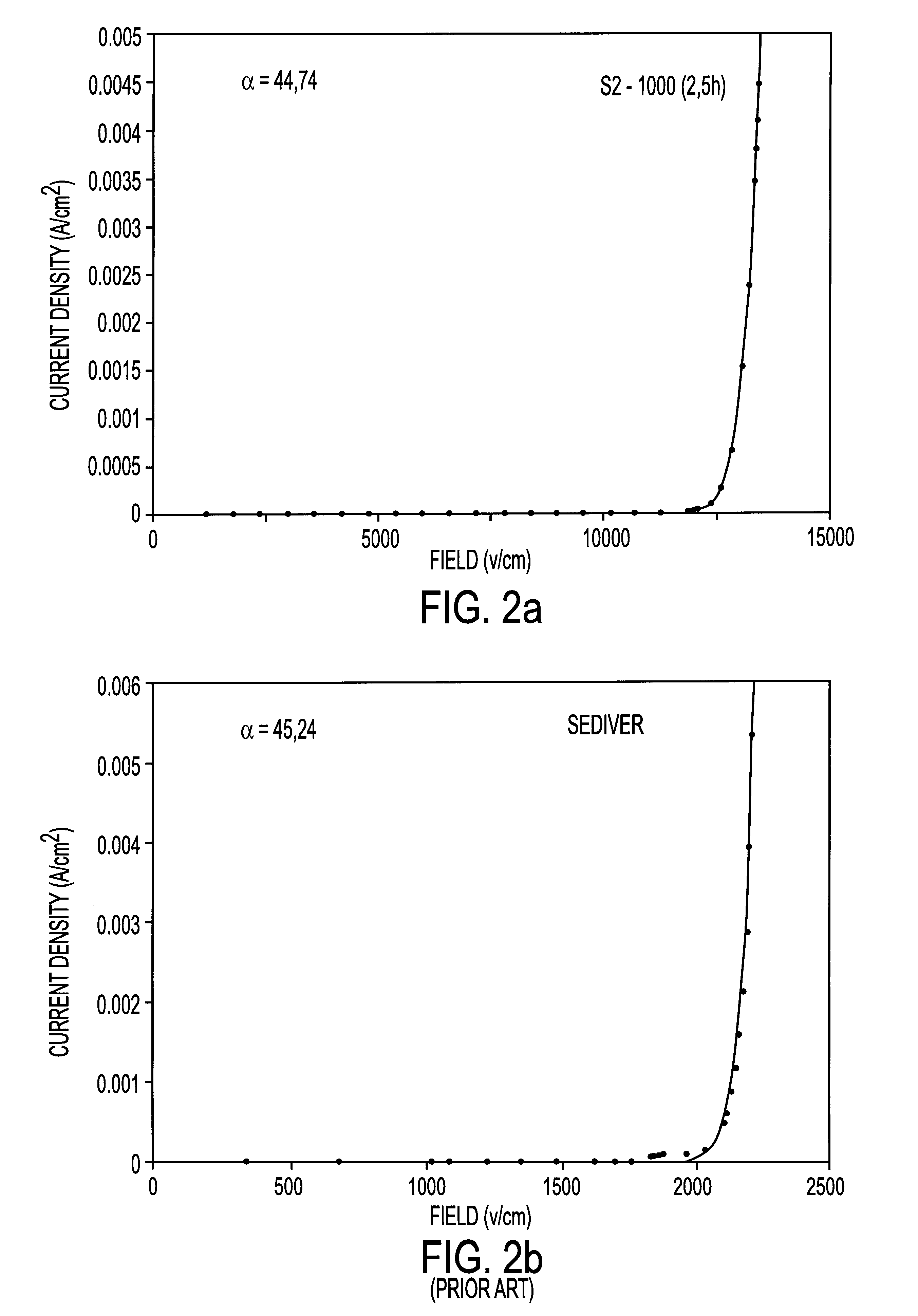

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

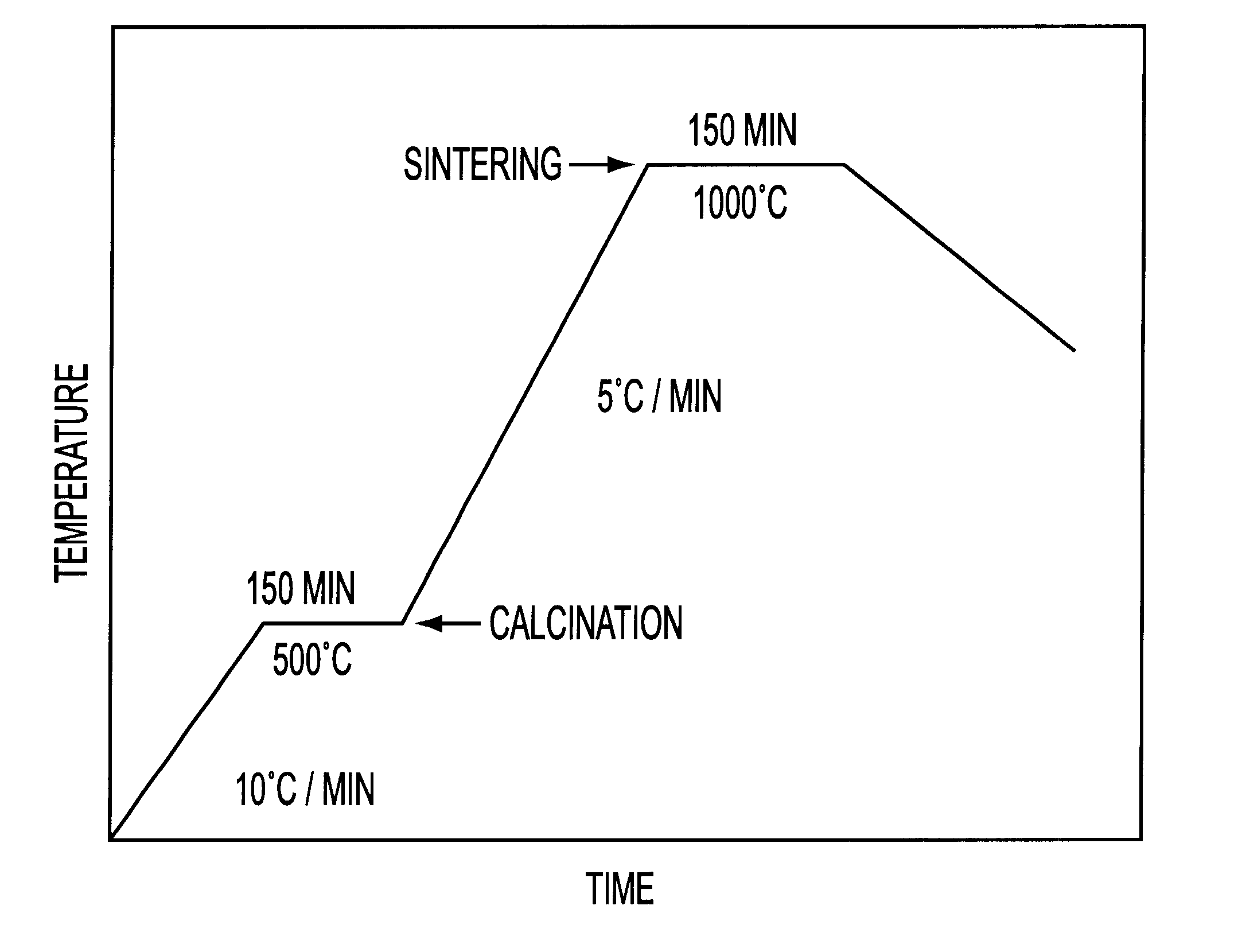

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

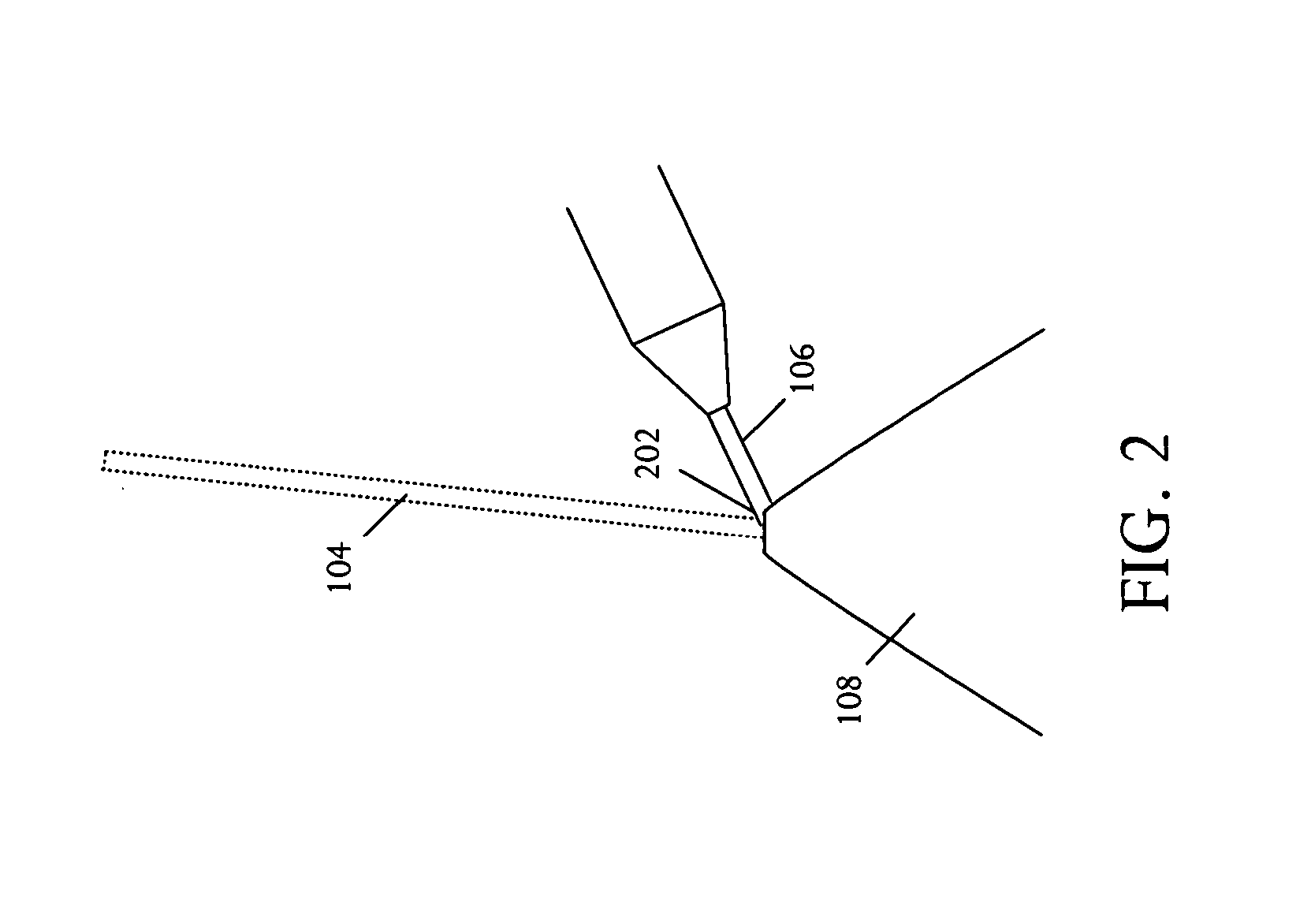

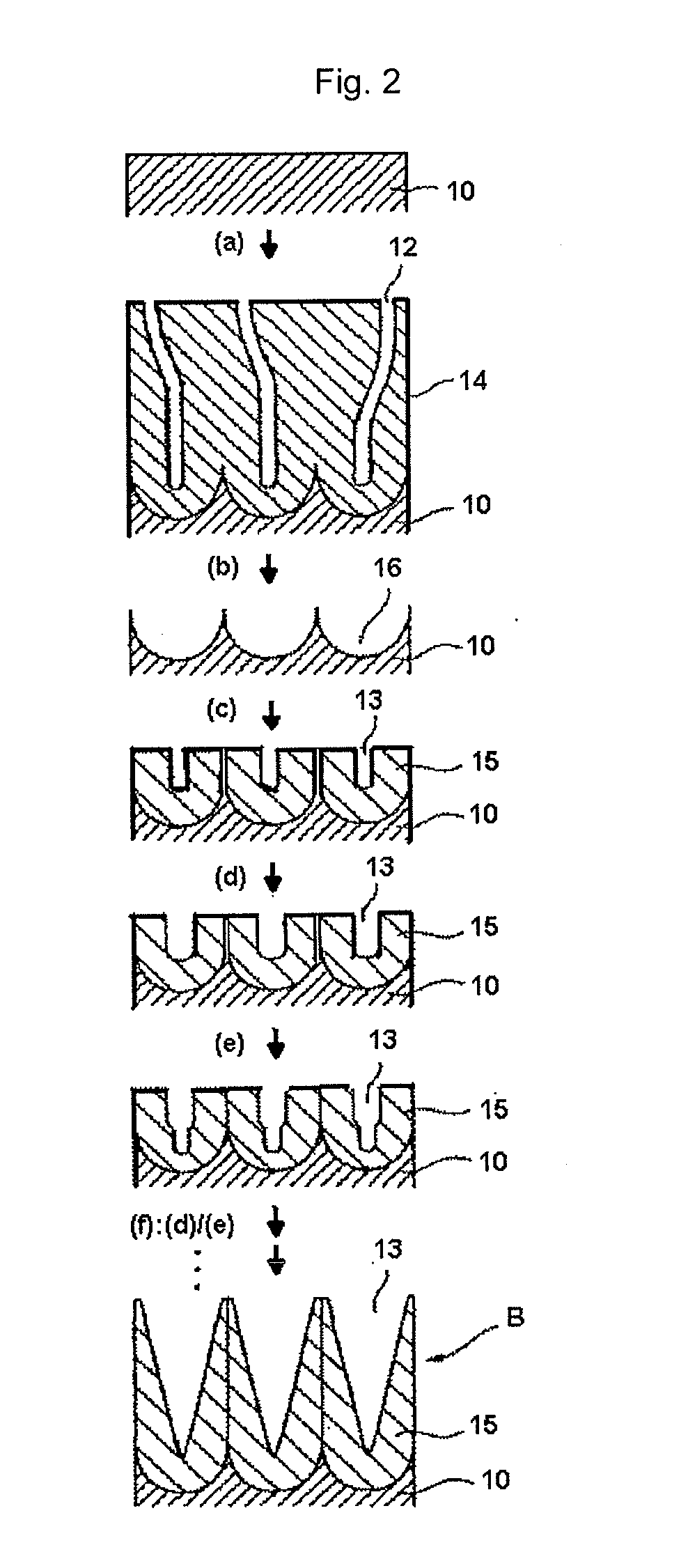

Warhead with integral, direct-manufactured features

InactiveUS20050235862A1Improve functionalityImprove permeabilityAmmunition projectilesAdditive manufacturing apparatusManufacturing technologyHigh energy

Owner:LOCKHEED MARTIN CORP

High purity niobium and products containing the same, and methods of making the same

InactiveUS20020072475A1Fine grain structureUniform textureCellsElectrolytic capacitorsNiobiumLog ratio

High purity niobium metals and alloys containing the same are described. The niobium metal preferably has a purity of at least 99.99% and more preferably at least 99.999%. In addition, niobium metal and alloys thereof are described, which either have a grain size of about 150 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 30 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the niobium metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity niobium metal which includes the step of reacting a salt-containing niobium and a metal salt along with at least one compound capable of reducing the salt-containing niobium to niobium and in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted niobium. The high purity niobium product preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

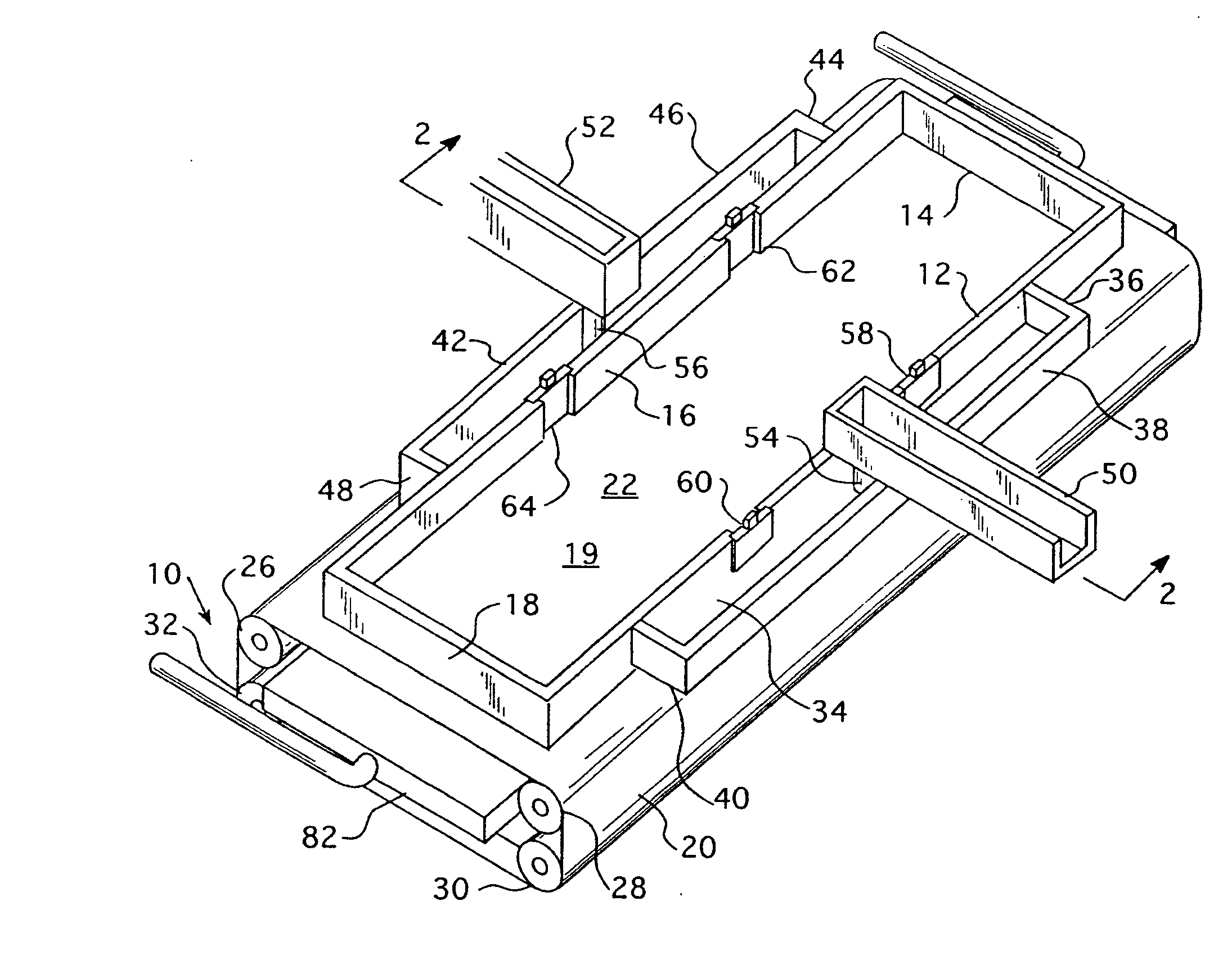

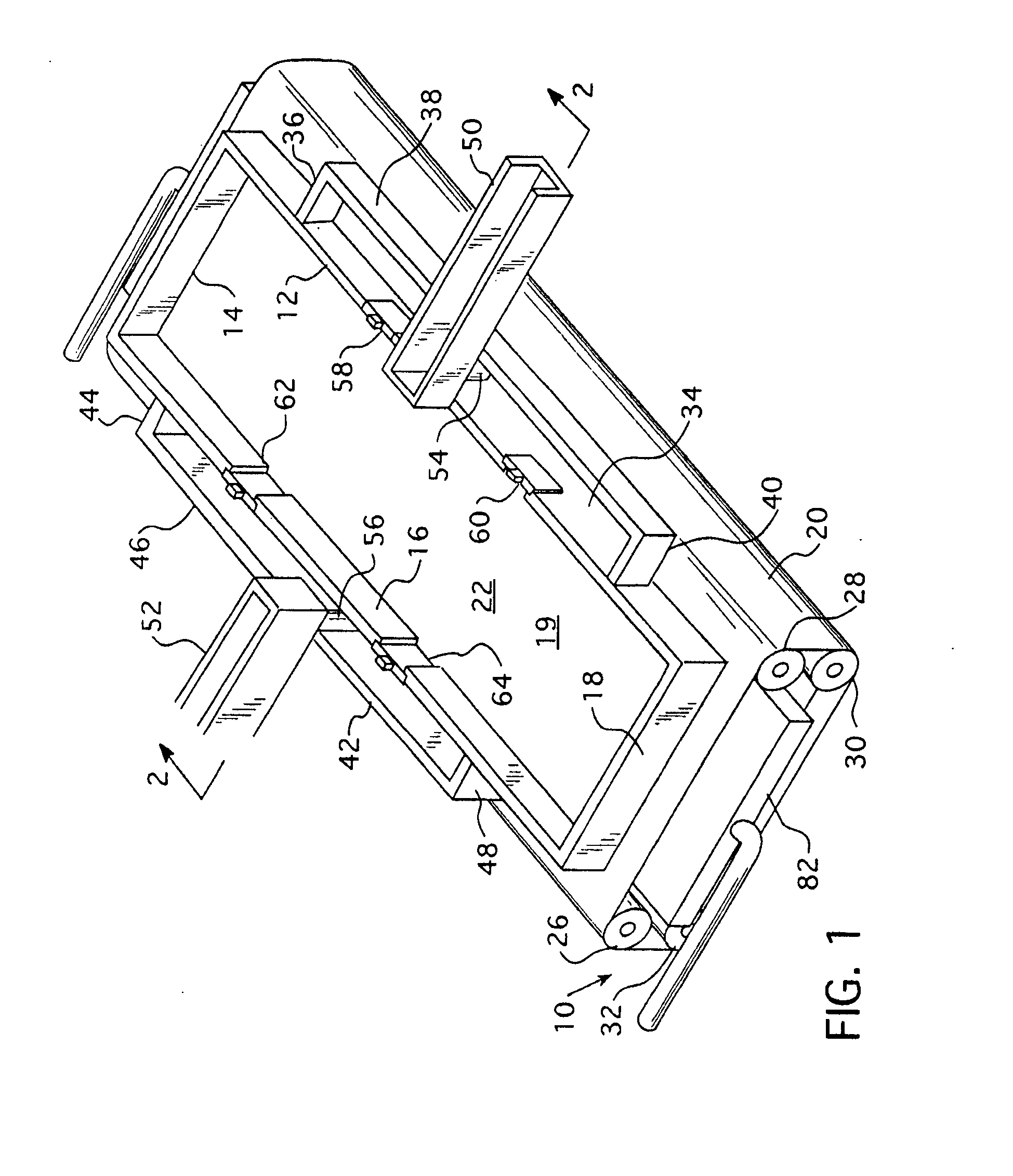

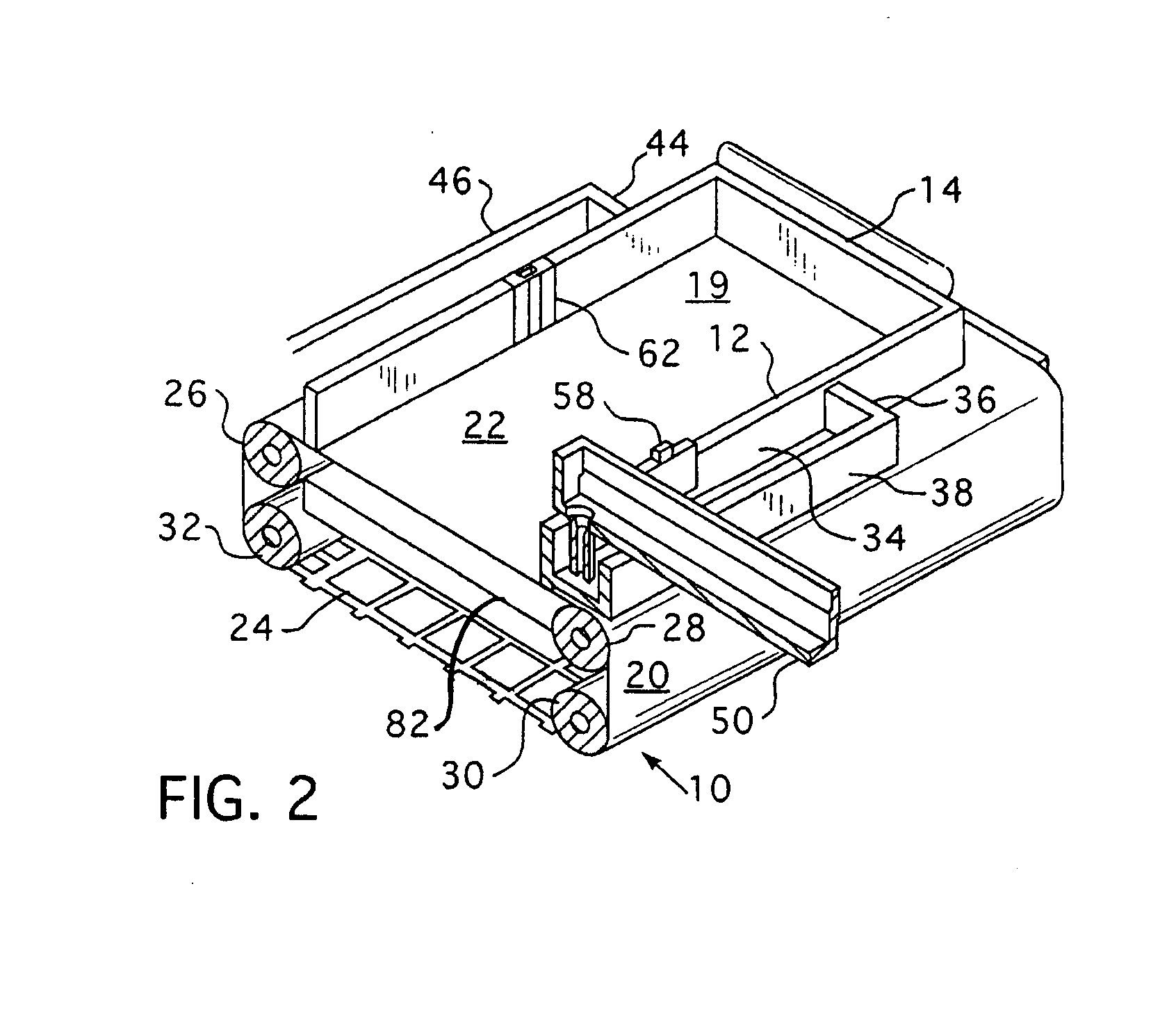

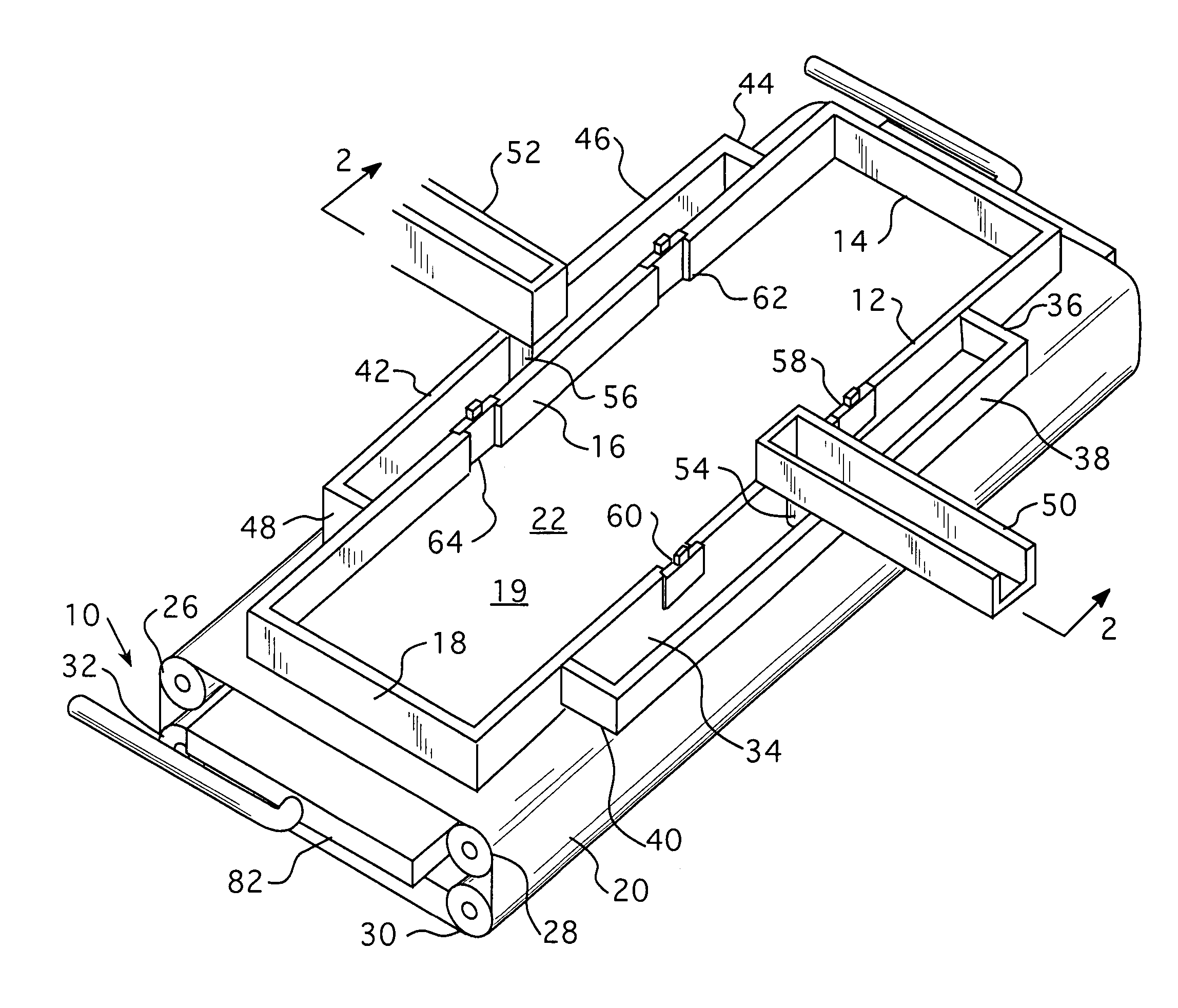

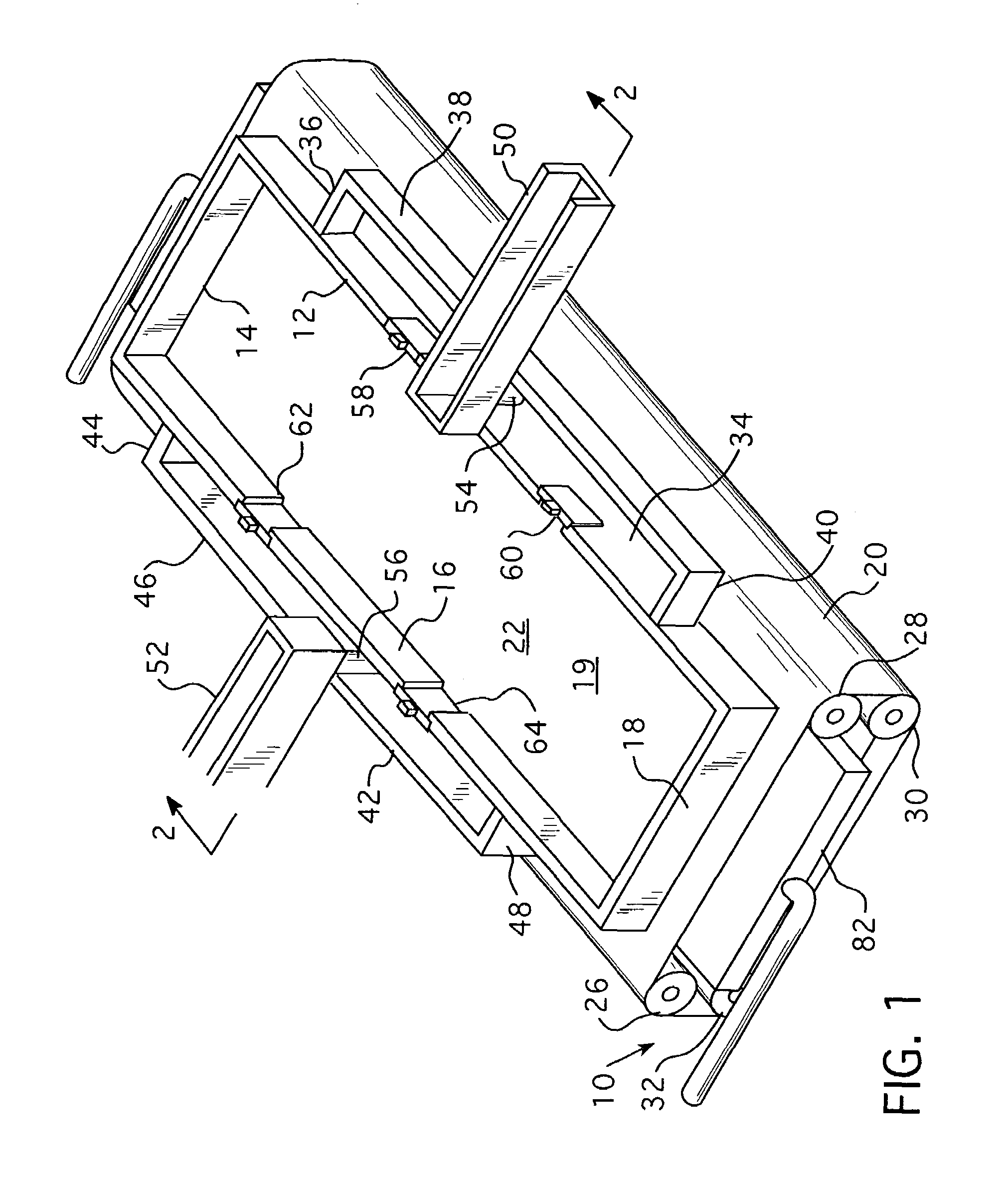

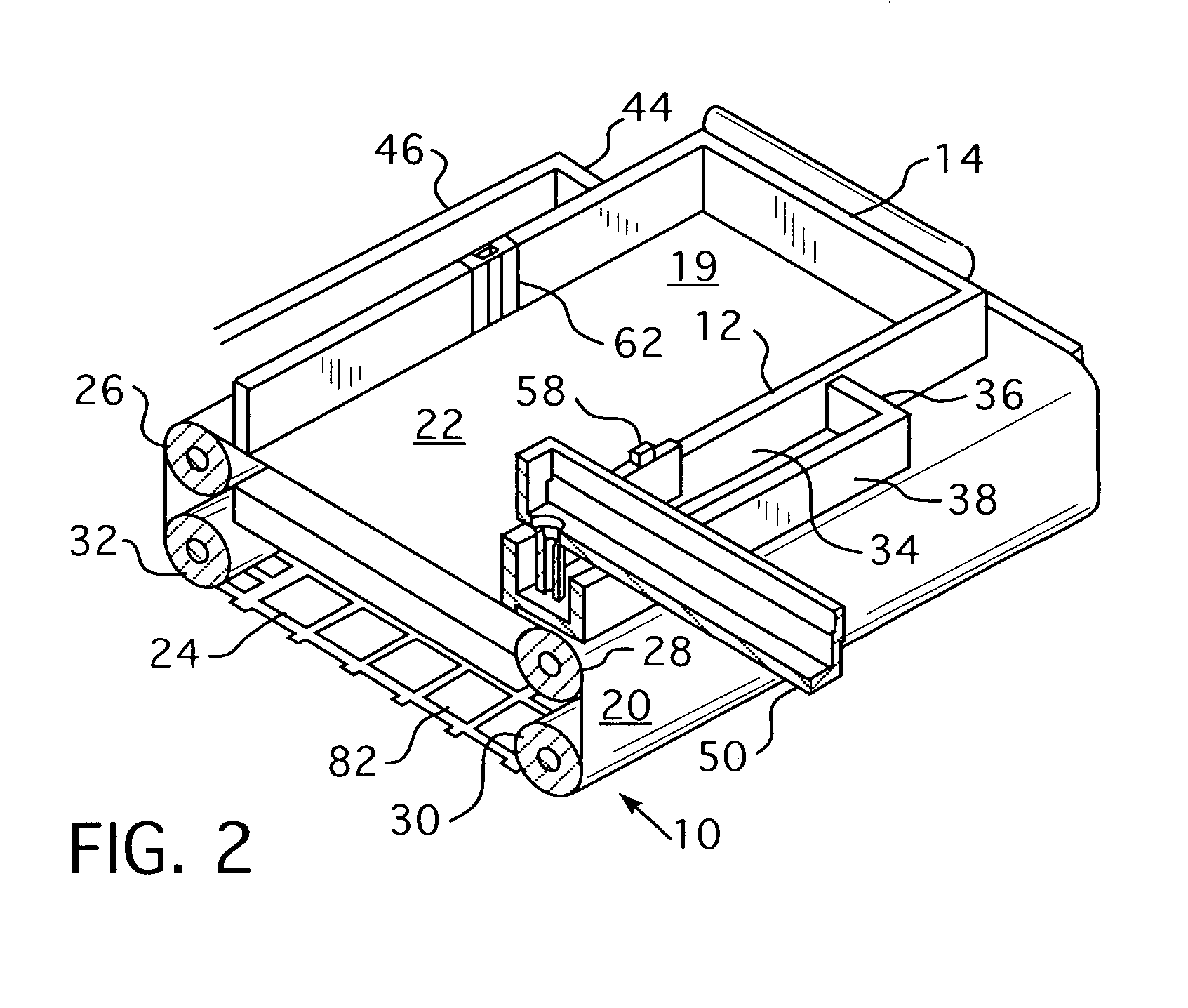

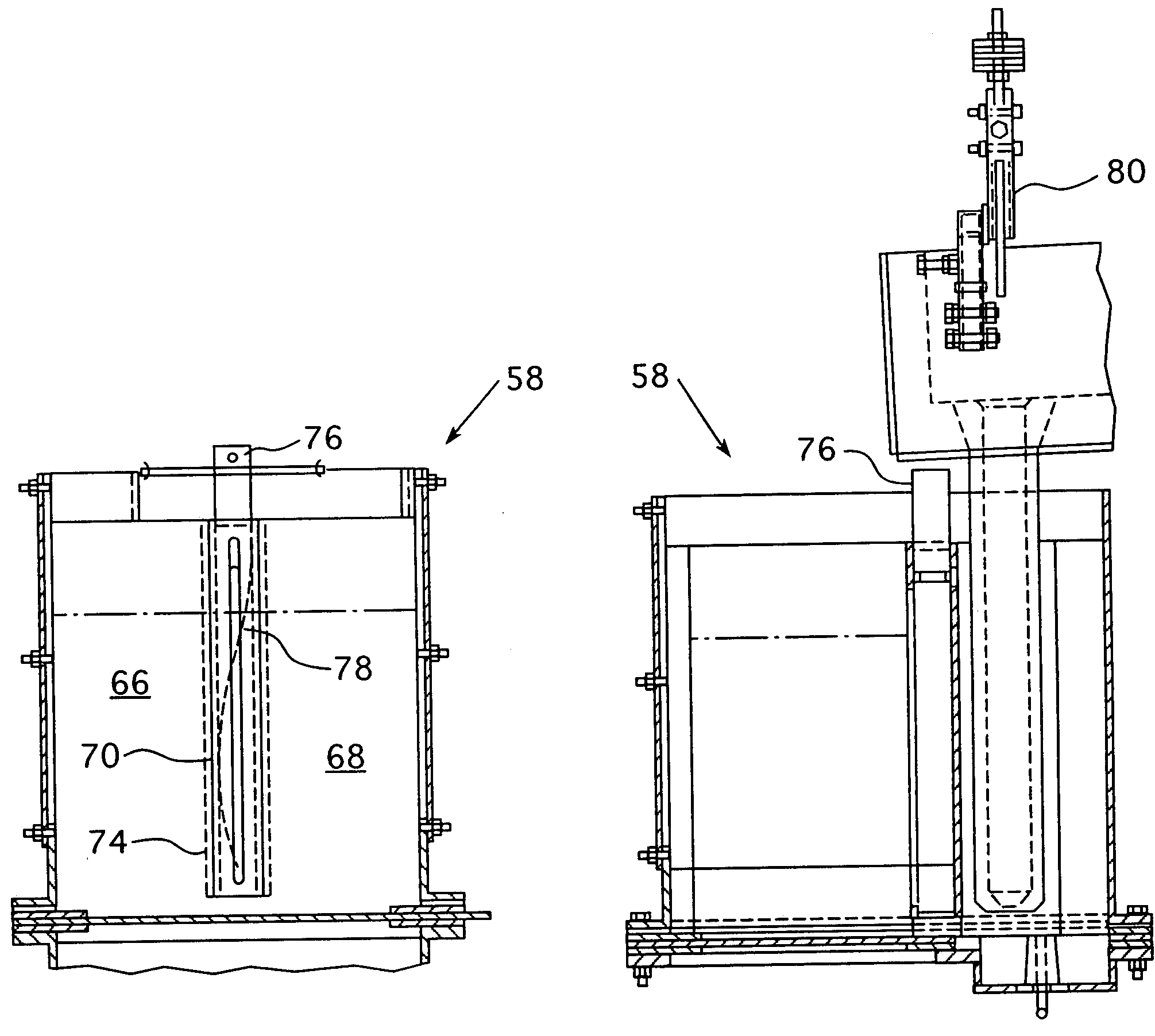

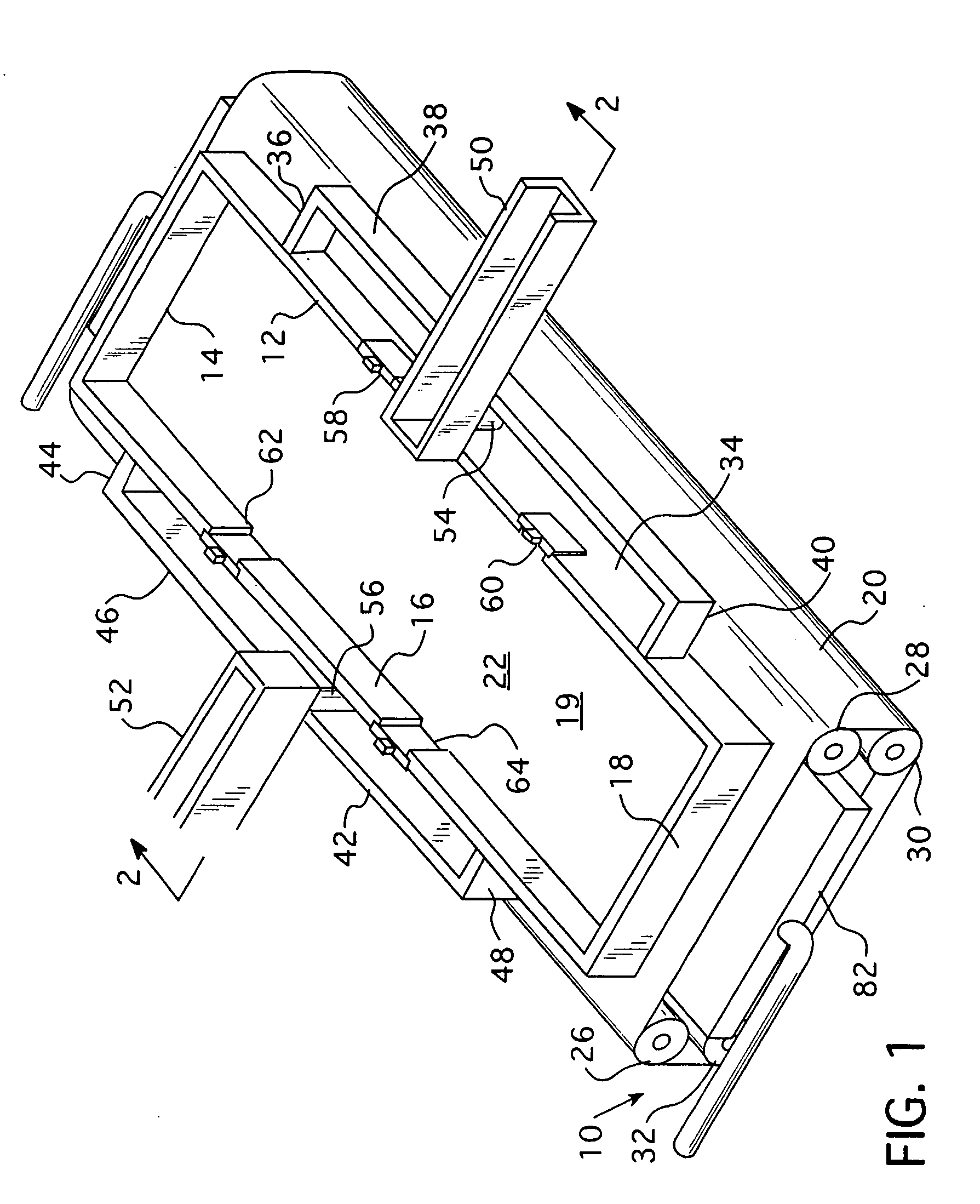

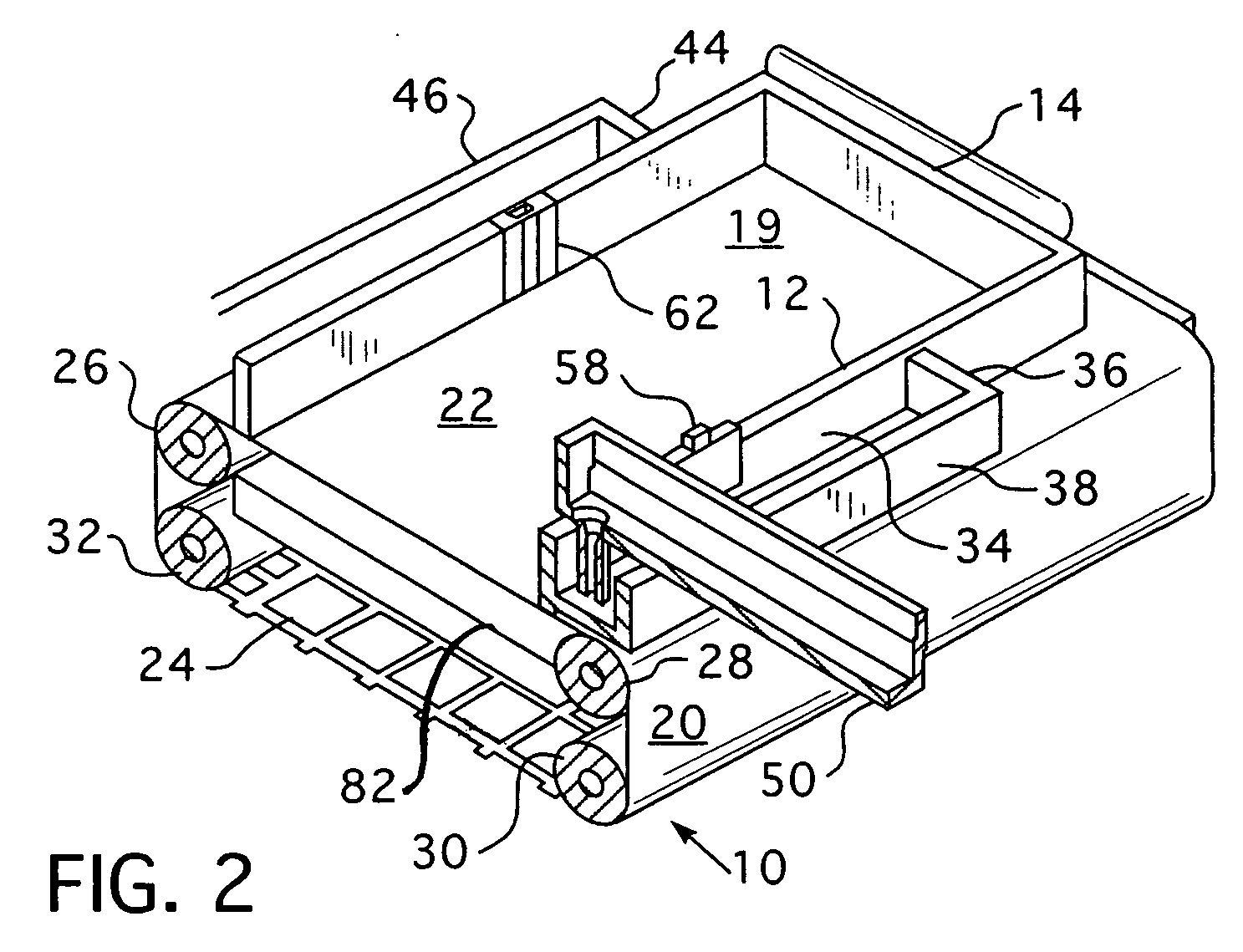

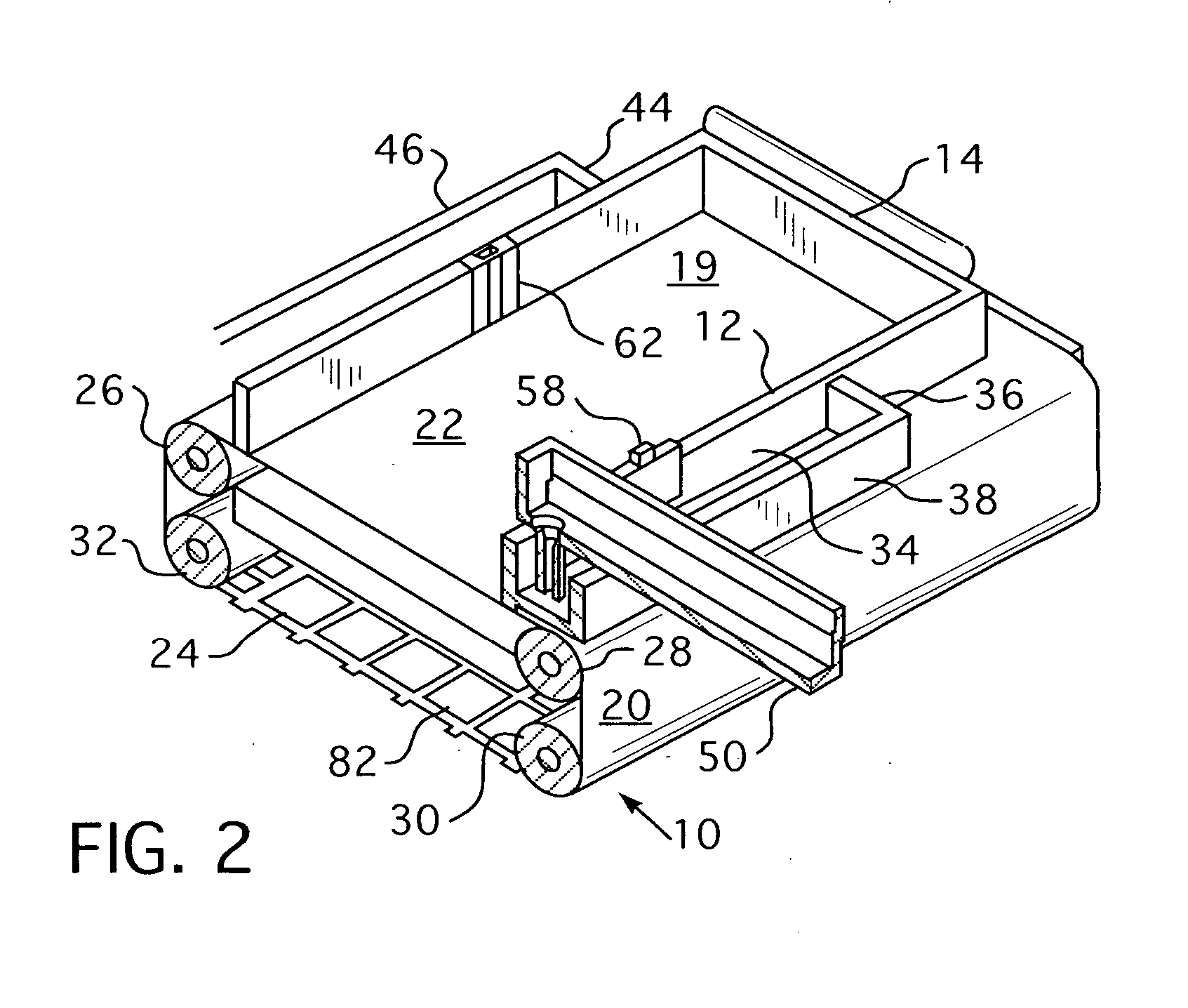

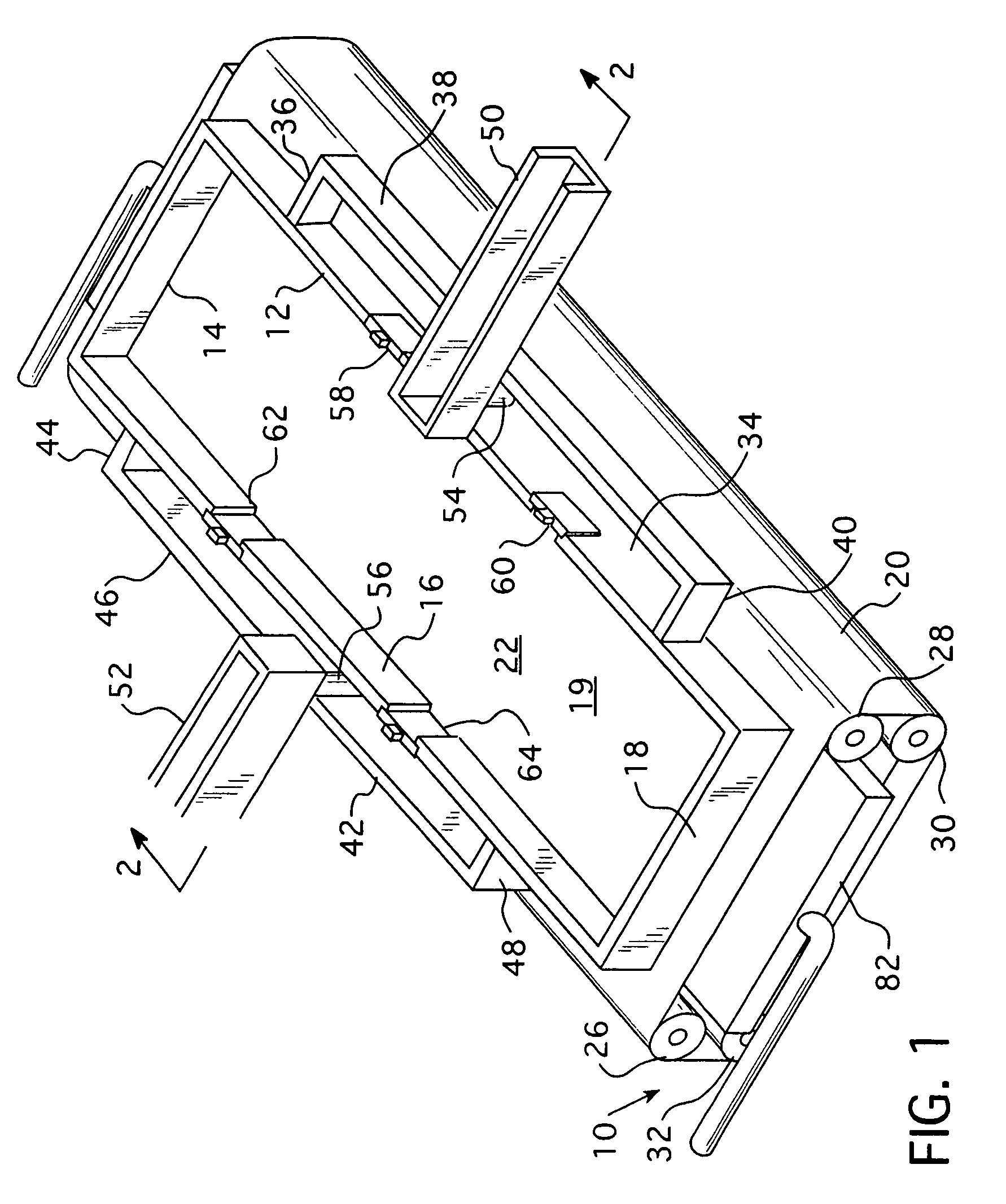

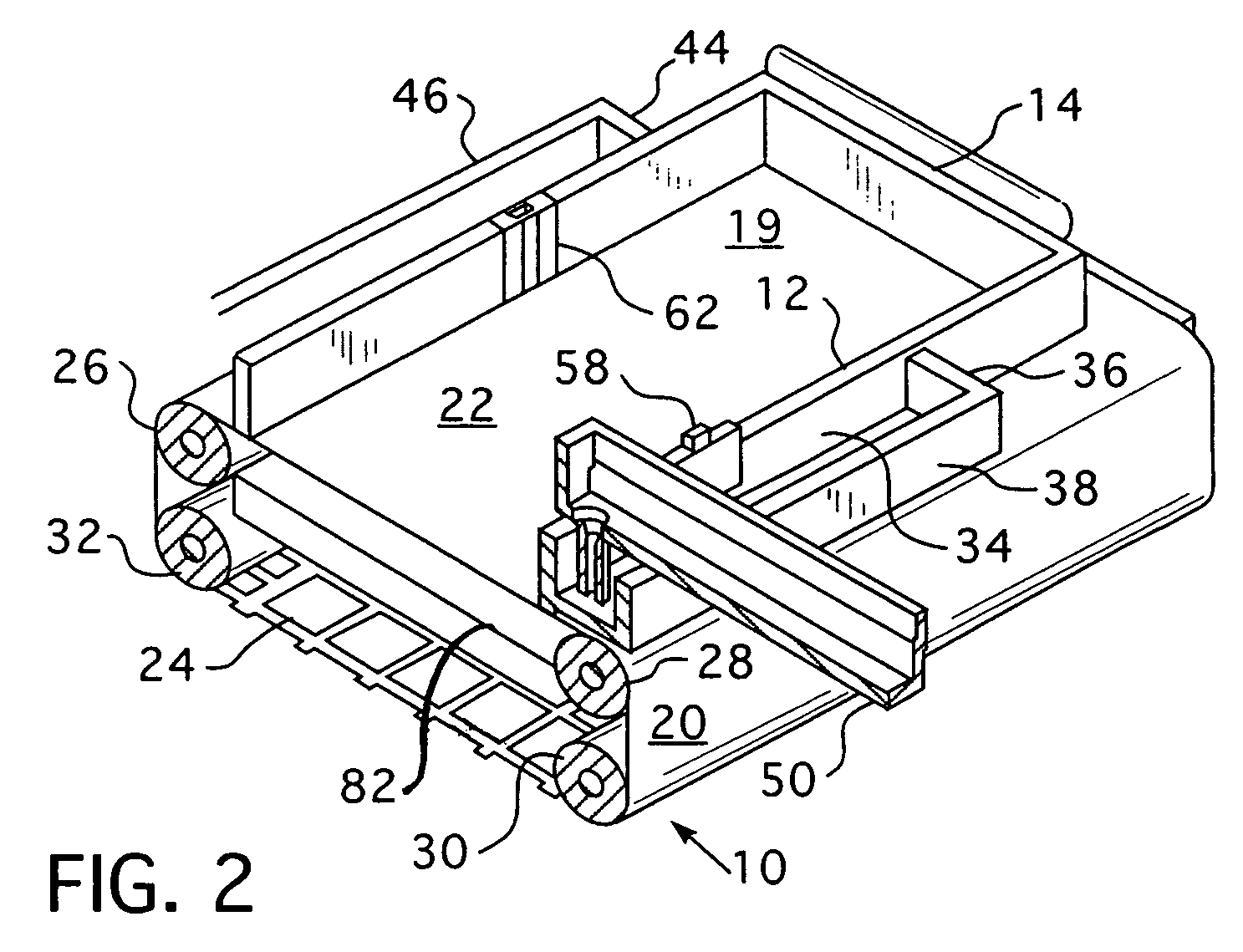

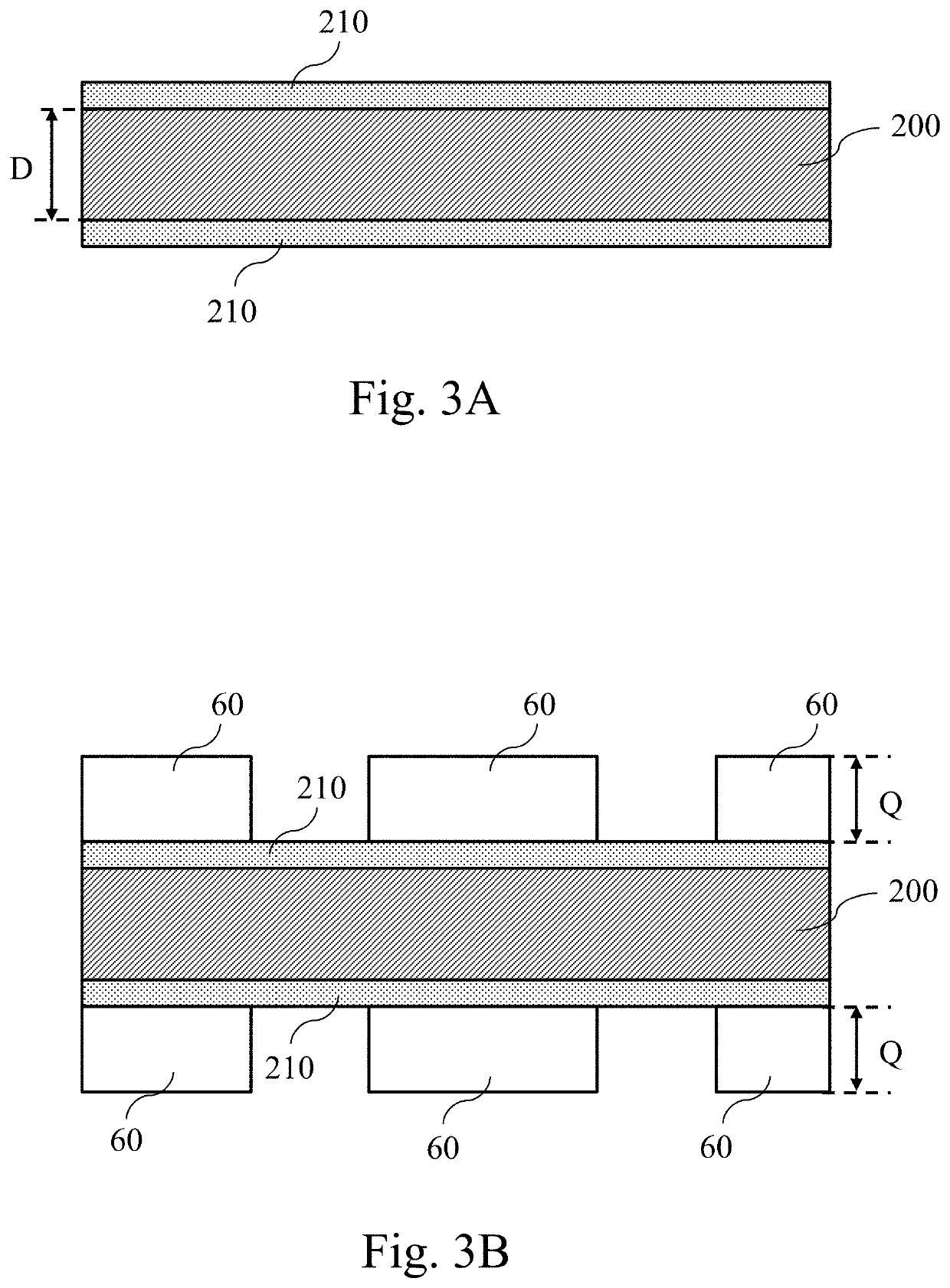

Method of unidirectional solidification of castings and associated apparatus

InactiveUS20080182122A1Simple methodConstant rateDomestic articlesThin material handlingMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

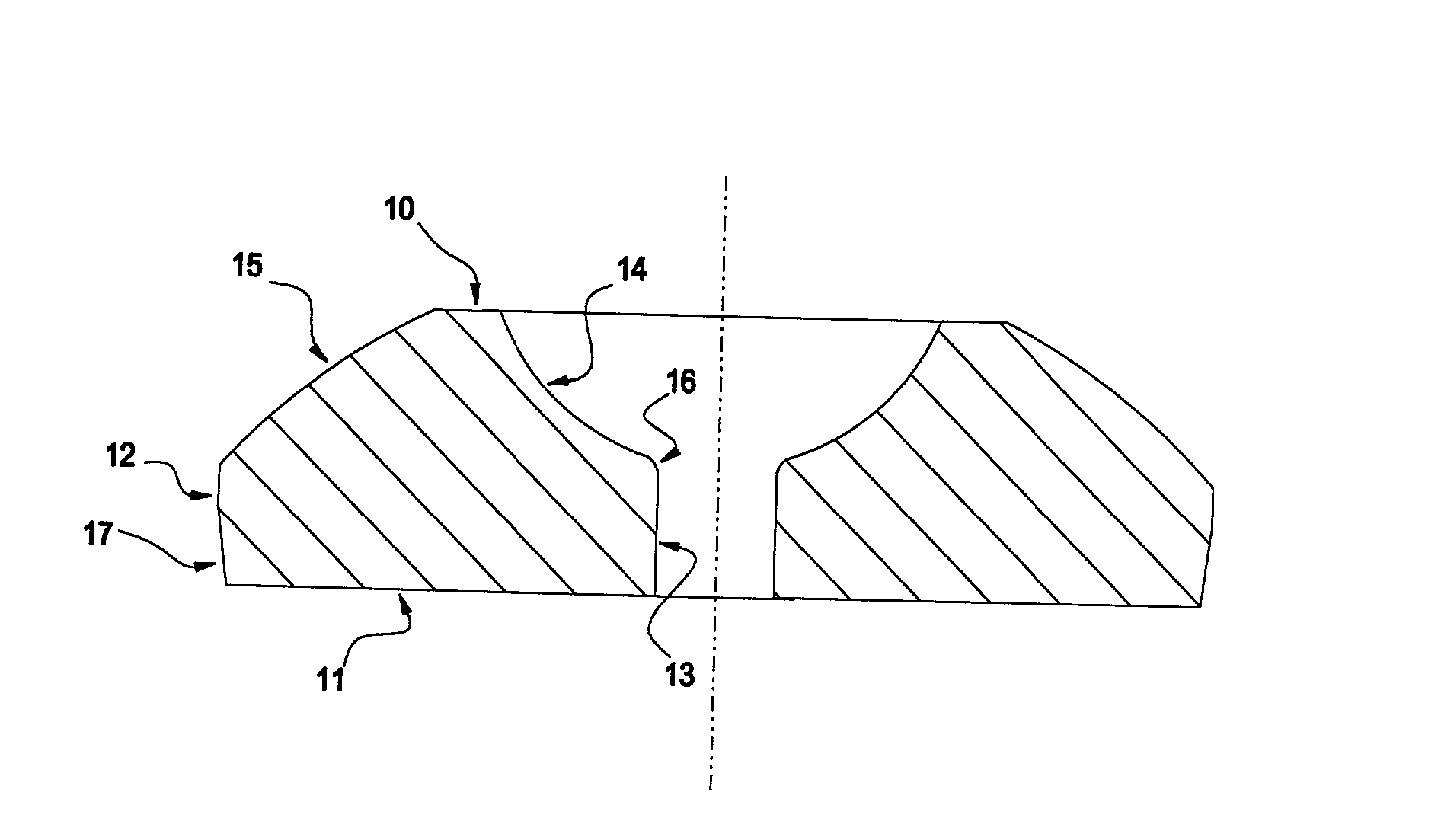

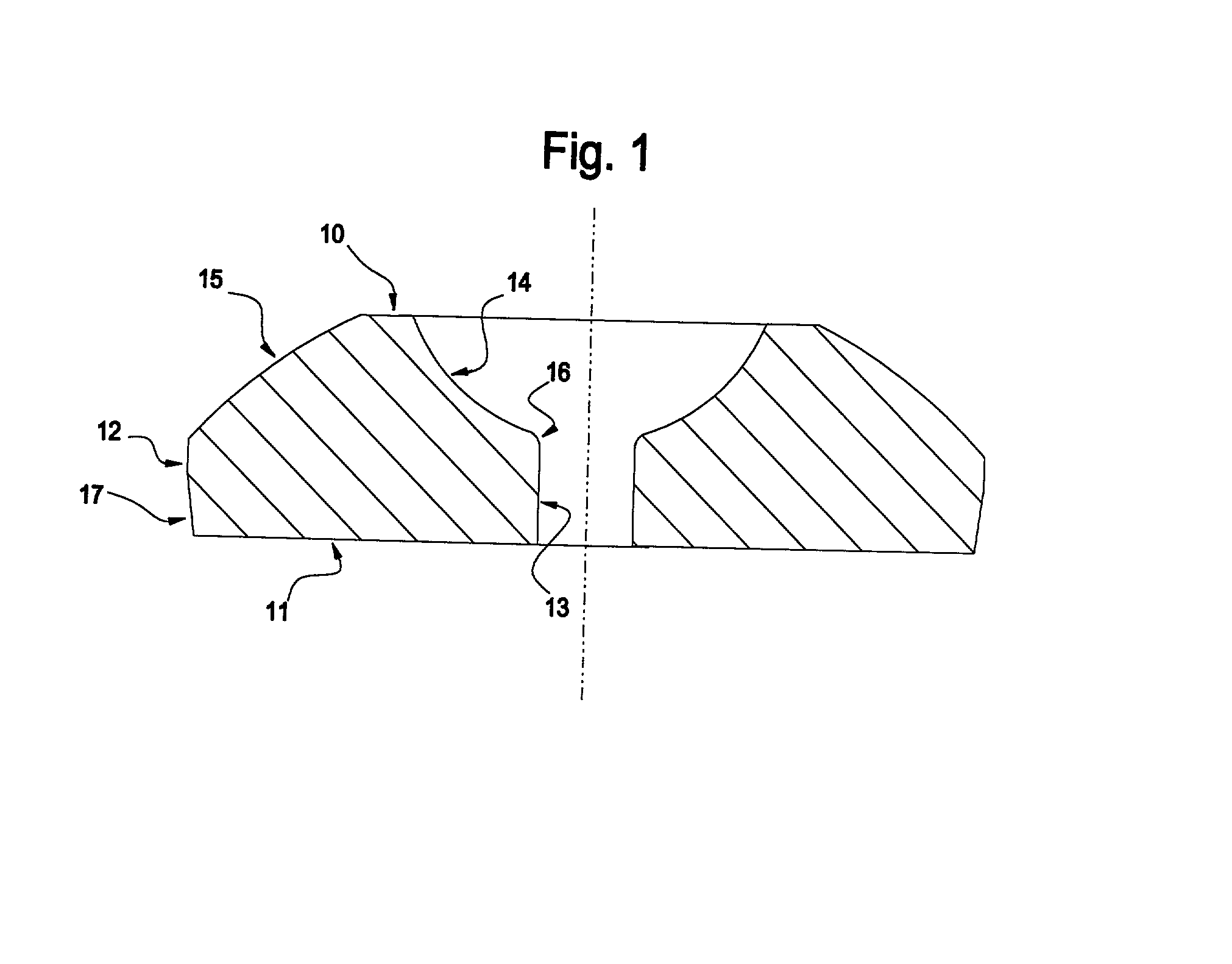

High purity tantalum, products containing the same, and methods of making the same

InactiveUS20020026965A1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingUltimate tensile strengthCapacitor

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995 % and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

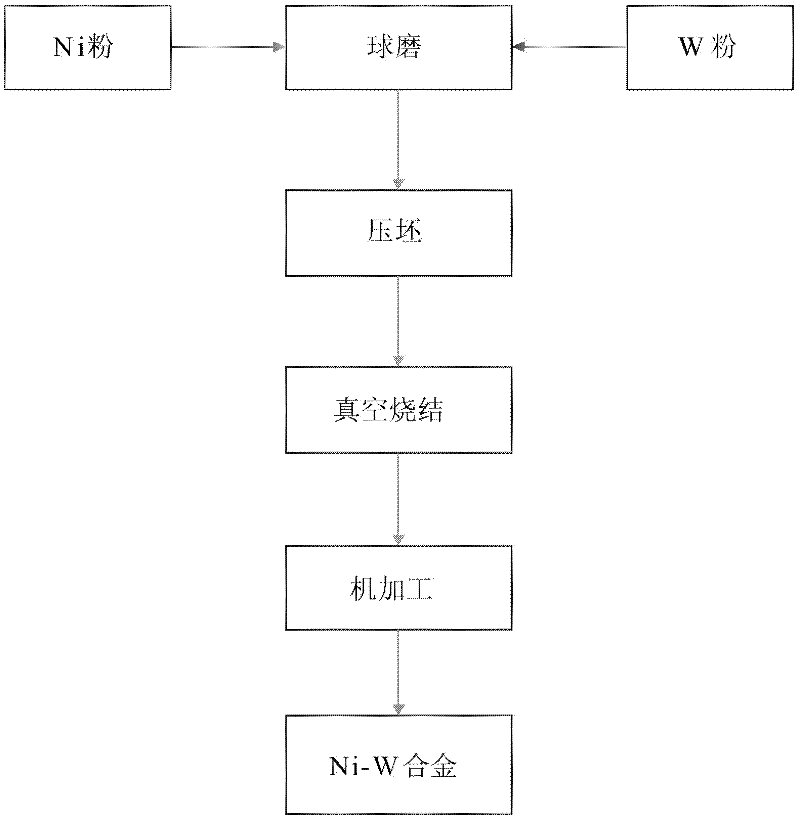

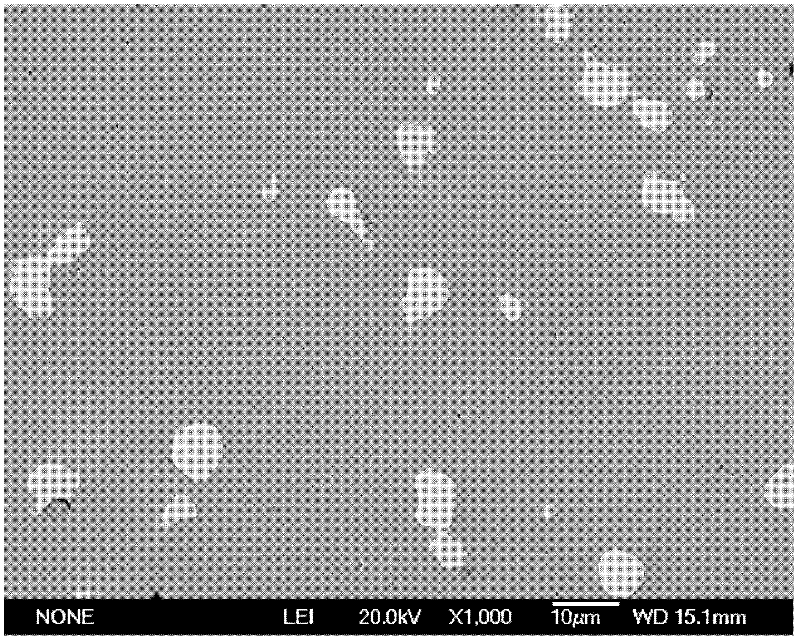

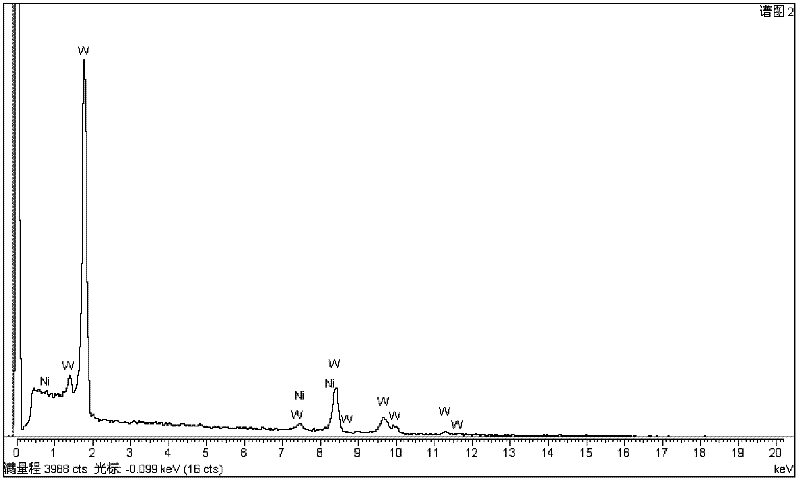

Method for preparing Ni-W alloy by vacuum sintering

The invention discloses a method for preparing Ni-W alloy by vacuum sintering, comprising the following steps of: using a Ni powder with its purity being no less than 99.9% and a W powder with its purity being no less than 99.9% as raw materials, carrying out ball milling on the two powders at different weight ratio at different time and at different ball milling ratio; compacting, carrying out vacuum sintering on the pressed compact, cooling in furnace, and finally machining the Ni-W alloy into a finished product. The method provided by the invention has simple preparation technology and requires low production cost. By the adoption of the method, nickel-tungsten alloy with high density and homogeneous microstructure can be prepared.

Owner:XIAN UNIV OF TECH

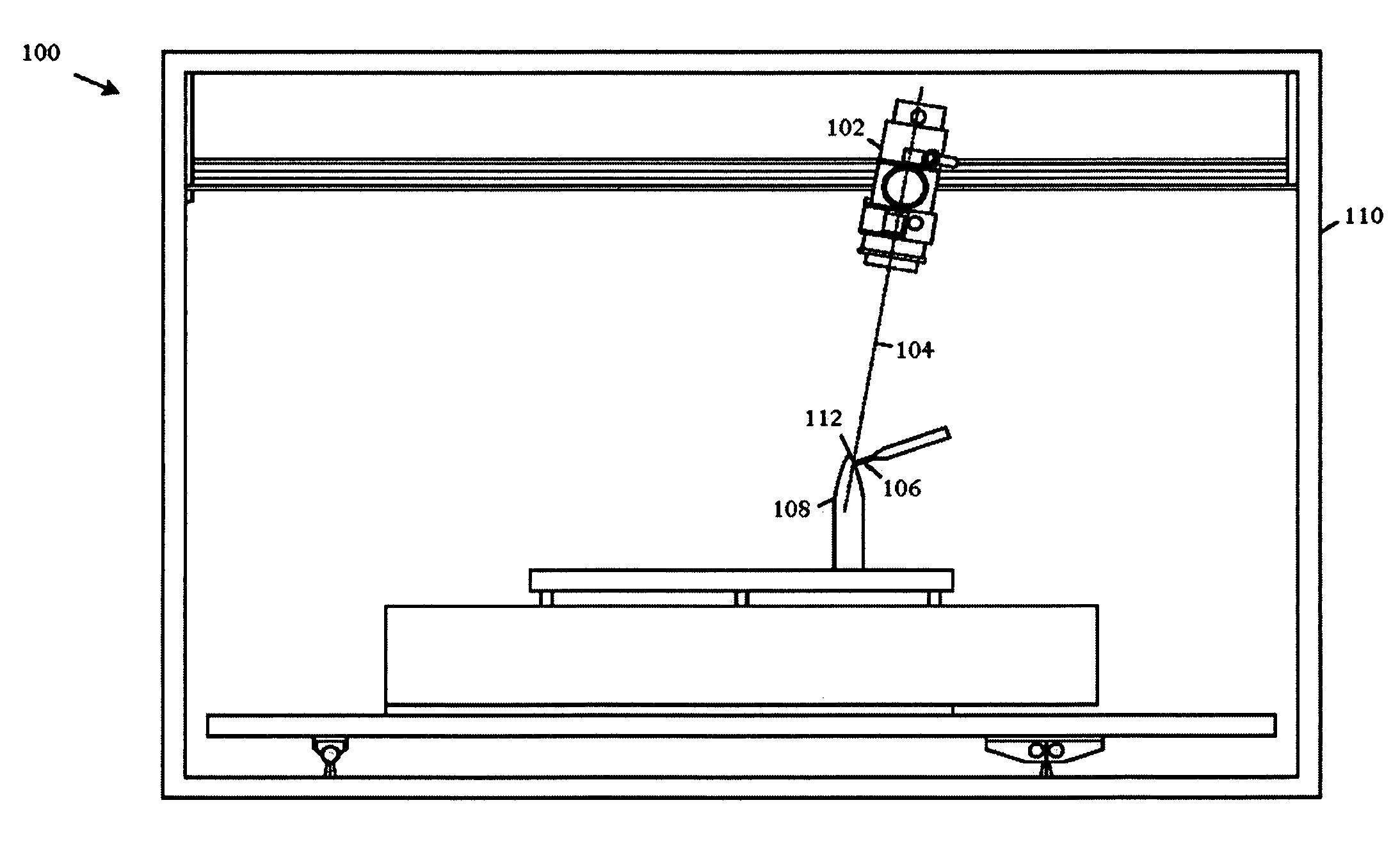

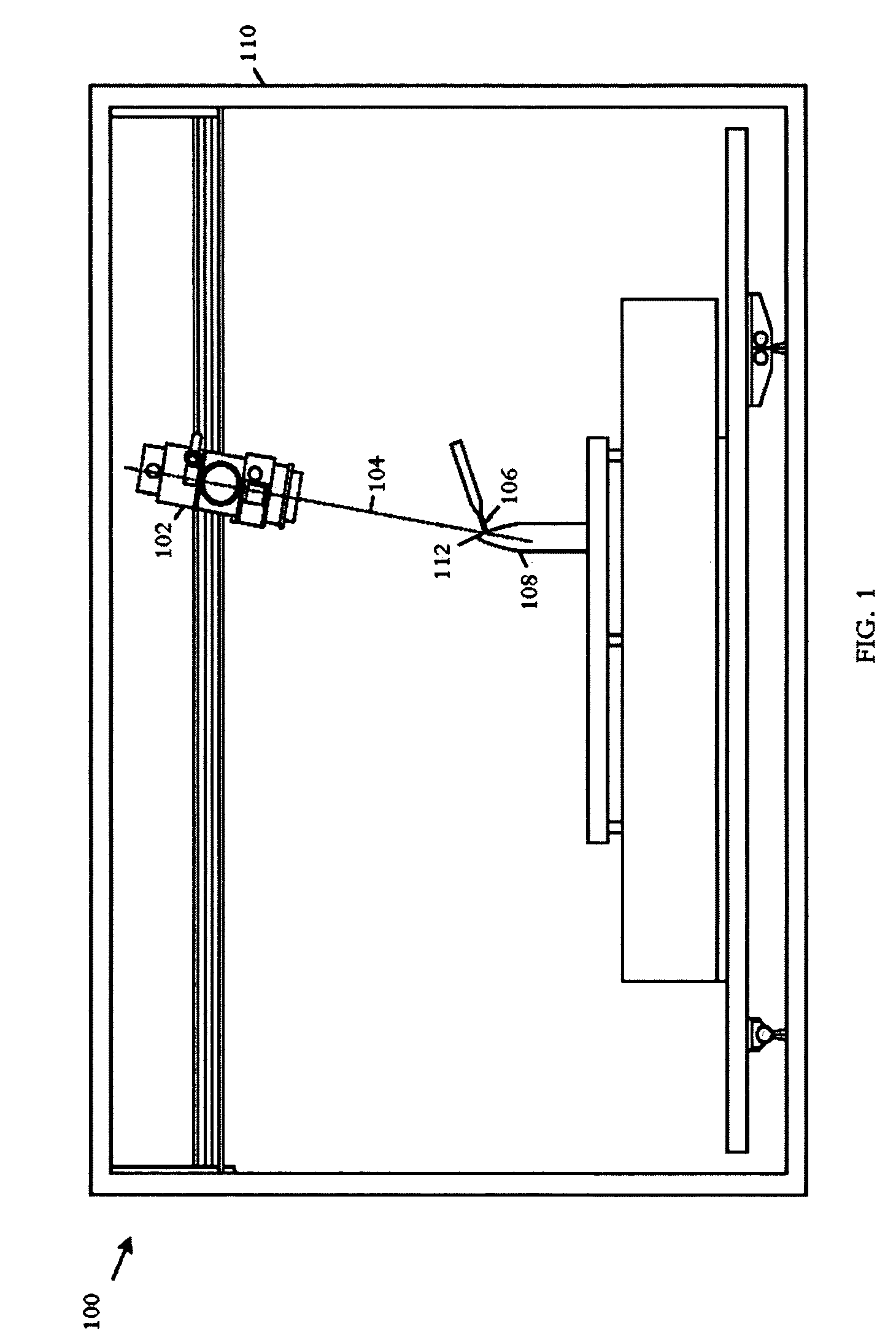

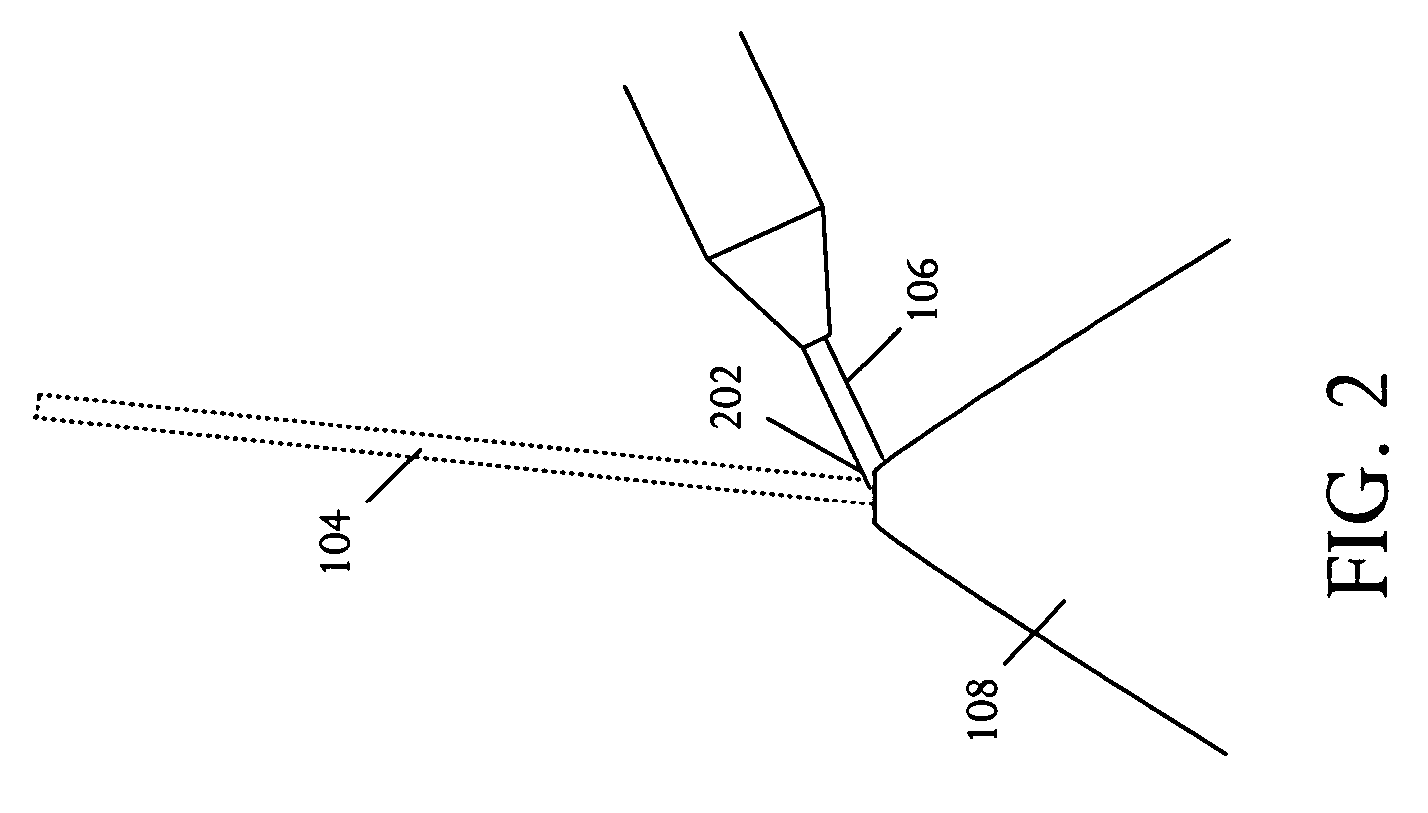

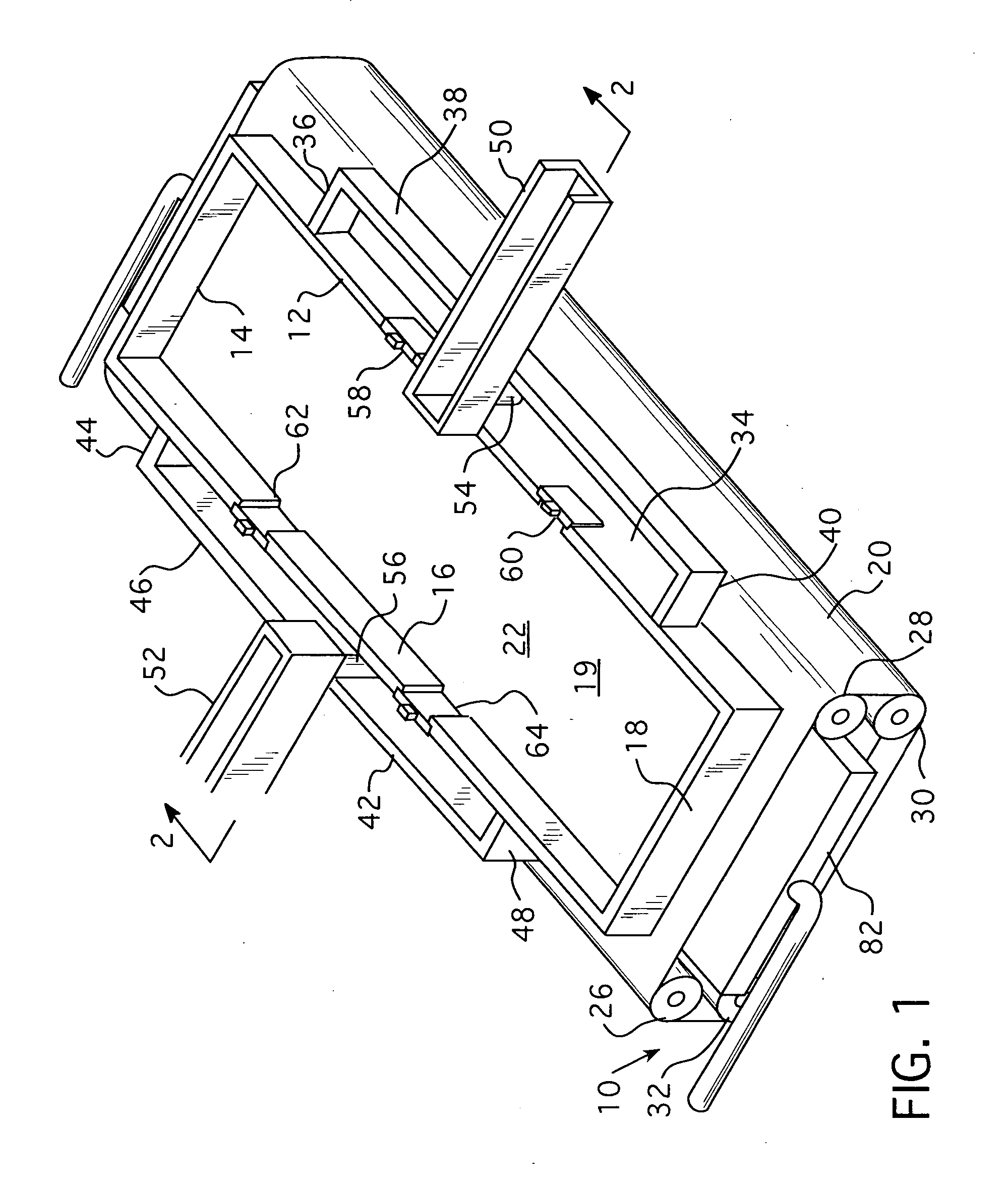

Warhead with integral, direct-manufactured features

InactiveUS7093542B2Optimized fragmentationImprove steering performanceAmmunition projectilesAdditive manufacturing apparatusManufacturing technologyHigh energy

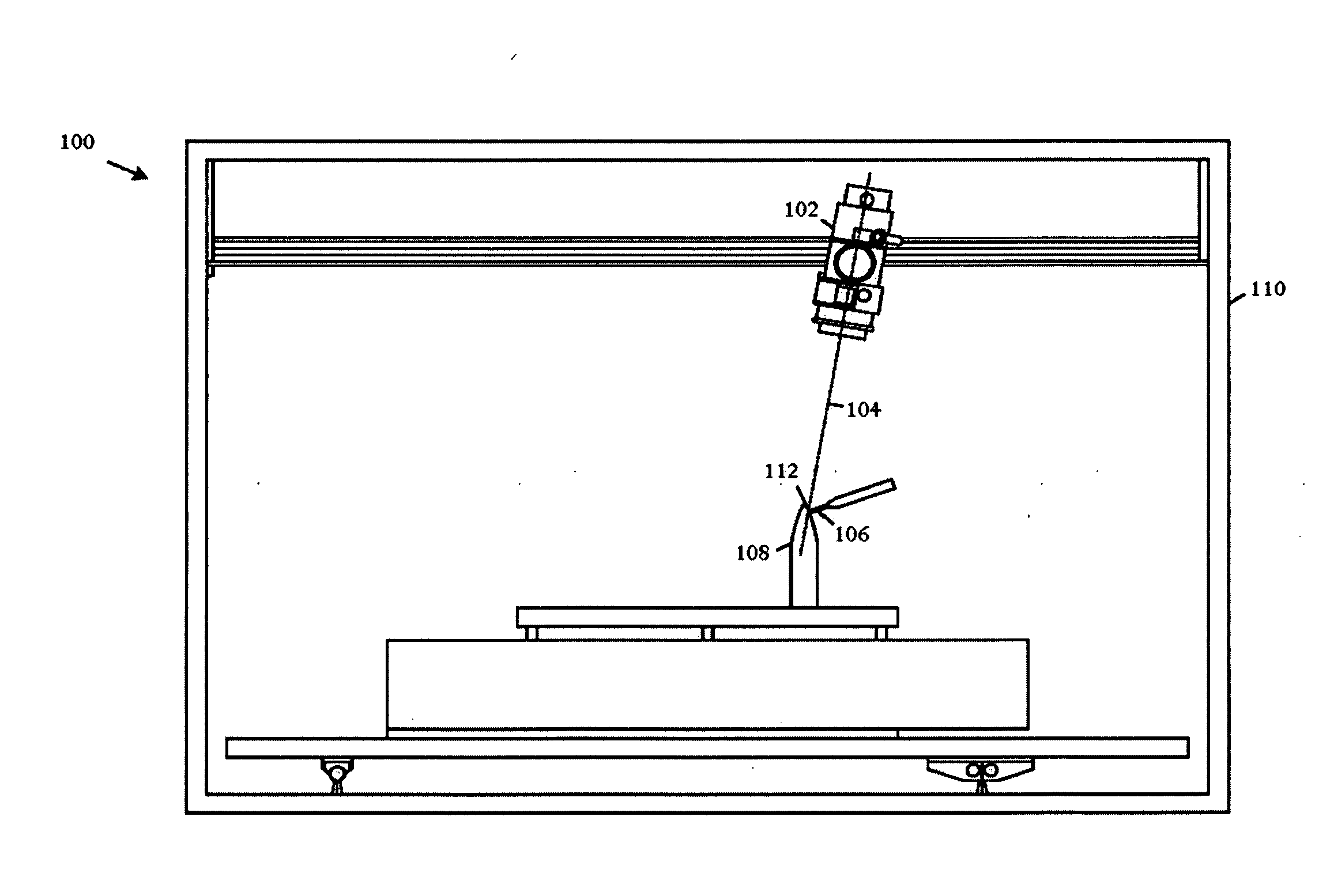

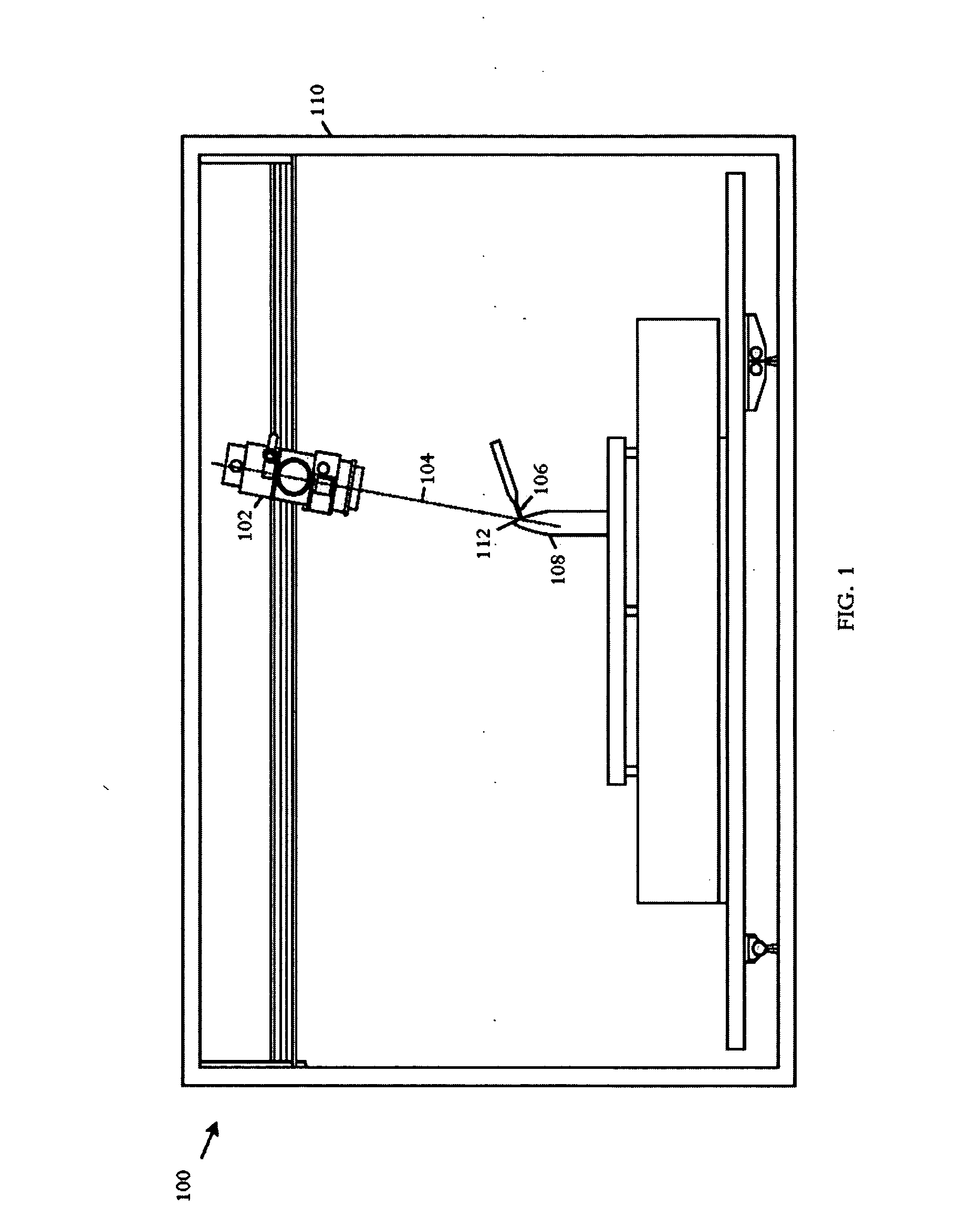

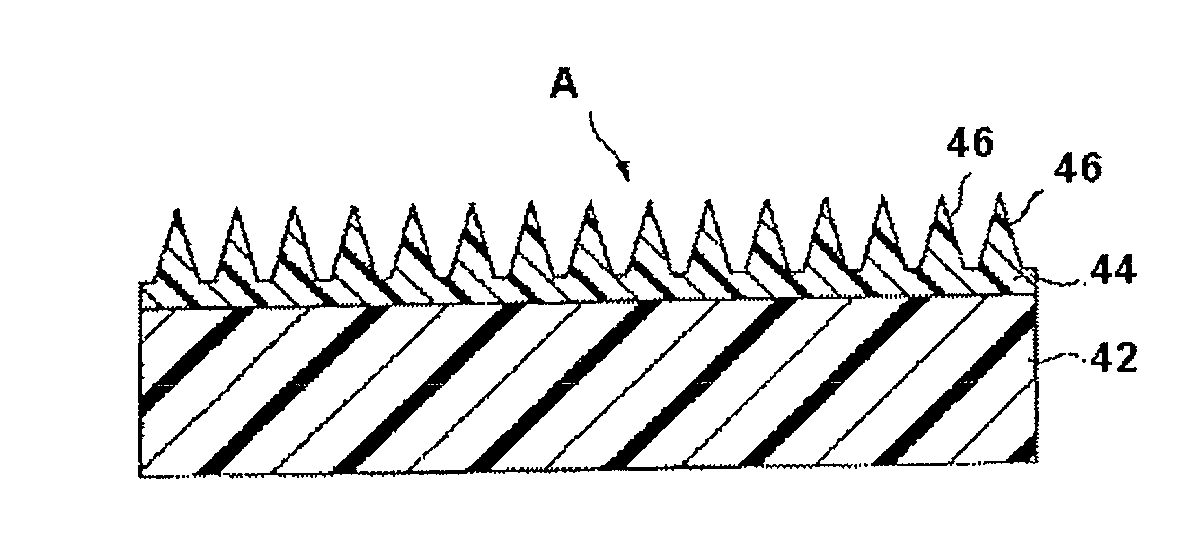

Warhead structures and features are fabricated using direct manufacturing technologies, a method for fabricating bulk warhead structures by sequential and additive deposition of melted feedstock layers. Suitable energy sources for melting the feedstock can be various high energy density technologies including laser, electron beam, plasma arc deposition, and the like. The high energy density in combination with high cooling rates results in structures with homogeneous microstructures. The feedstock can be in the form of wire or powder and is applied to a substrate by introduction to a molten pool on the substrate, accumulating to additively combine with the substrate. The approach provides for warhead structures with singular and combined unique features to include: integral constructions, tailored fragmentation patterns, use of dissimilar materials for special effects, and variable material property constructions for enhanced performance.

Owner:LOCKHEED MARTIN CORP

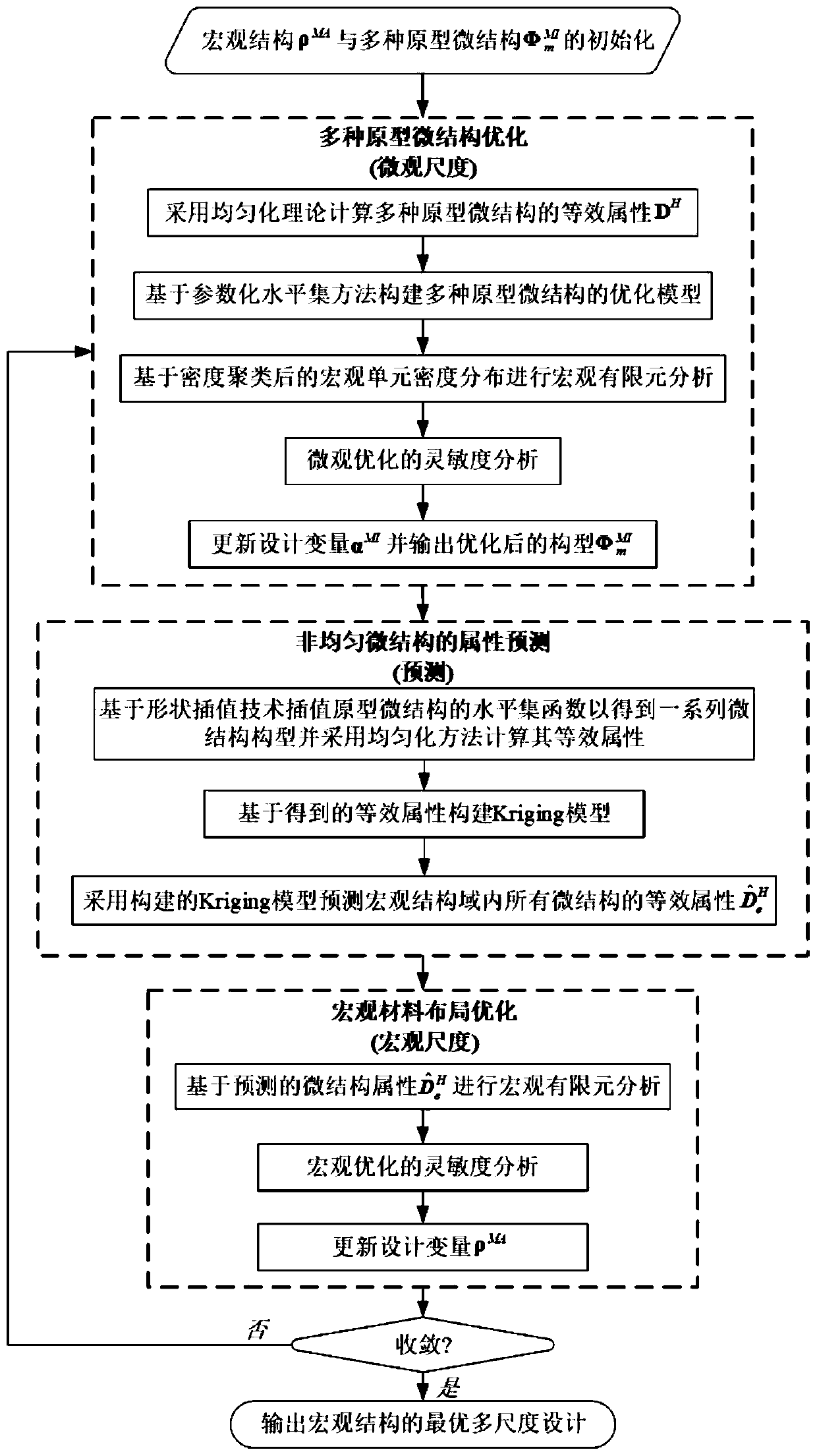

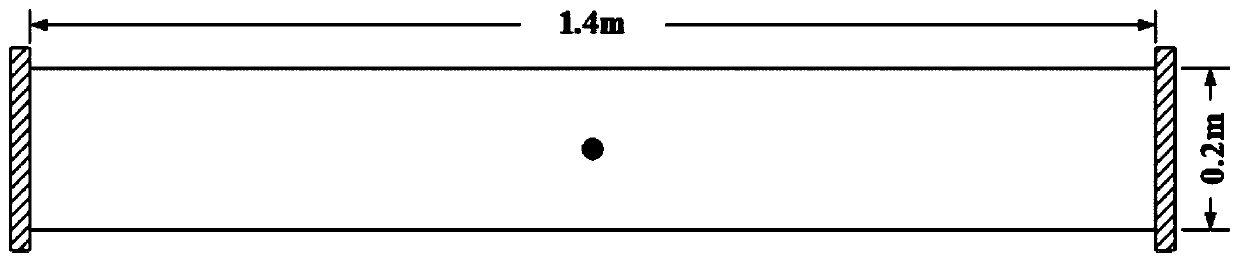

Multi-scale topology optimization method based on an agent model

InactiveCN109871574AFirmly connectedReduce computing costSpecial data processing applicationsVariable thicknessMacroscopic scale

The invention belongs to the technical field of structural optimization design, and discloses a multi-scale topology optimization method based on an agent model. The method comprises the following steps: (1) optimizing by adopting a topological optimization method based on a parameterized level set to obtain optimal topological configurations of various prototype microstructures; (2) carrying outinterpolation on the optimized level set function of the prototype microstructure to obtain equivalent attributes of the non-uniform microstructure, and then constructing a prediction model by takingthe non-uniform microstructure as a sample point to predict the equivalent attributes of all macroscopic units in a macroscopic structure domain; and (3) optimizing material distribution in the macrostructure domain by adopting a variable thickness method, so that the performance of the macrostructure is optimal. By means of the method, the geometric and pointwise macroscopic unit configurations of the macroscopic structure and the joint optimization of the positions of the macroscopic unit configurations in the macroscopic structure domain are achieved, the material potential is brought intoplay to the maximum extent with the low calculation cost, material consumption is saved, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

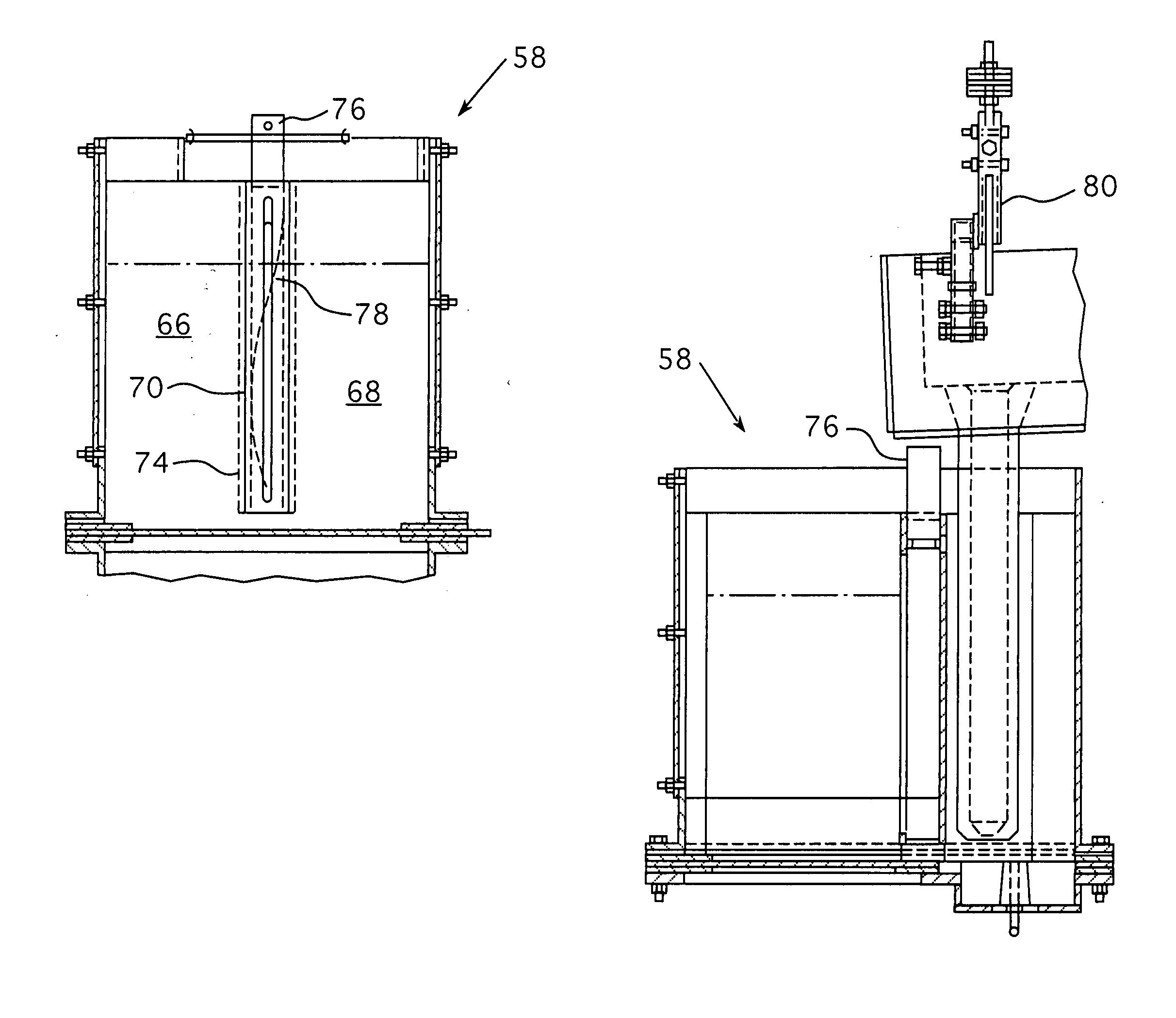

Method of unidirectional solidification of castings and associated apparatus

InactiveUS7264038B2Simple methodConstant rateMelt-holding vesselsMolten metal pouring equipmentsHomogeneous microstructureMolten metal

Owner:ARCONIC INC

Method of unidirectional solidification of castings and associated apparatus

InactiveUS20070012417A1Reduce stressReduce probabilityMelt-holding vesselsMolten metal pouring equipmentsMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

Polycrystalline watch jewels and method of fabrication thereof

InactiveUS20020135108A1Economic and simple and energyEconomic and simple and and materialMaterial nanotechnologyTransportation and packagingMetallurgyNet shape

A method to produce polycrystalline sapphire or ruby watch jewels is disclosed. Green watch jewels are formed from a mixture of fine ceramic powders with a thermoplastic binder. Following extraction of the binder the parts are sintered to net shape and full density. The method obviates the inefficient and labor intensive technique of monocrystalline watch jewel manufacturing. The purity of the raw materials and processing conditions result in sintered polycrystalline rubies or sapphires with homogeneous microstructures, small grain size and hardness similar to that of their synthetic monocrystalline counterparts.

Owner:BILLIET ROMAIN L +1

Method of unidirectional solidification of castings and associated apparatus

InactiveUS20070012416A1Reduce stressReduce probabilityMelt-holding vesselsMolten metal pouring equipmentsHomogeneous microstructureMolten metal

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting.

Owner:ARCONIC INC

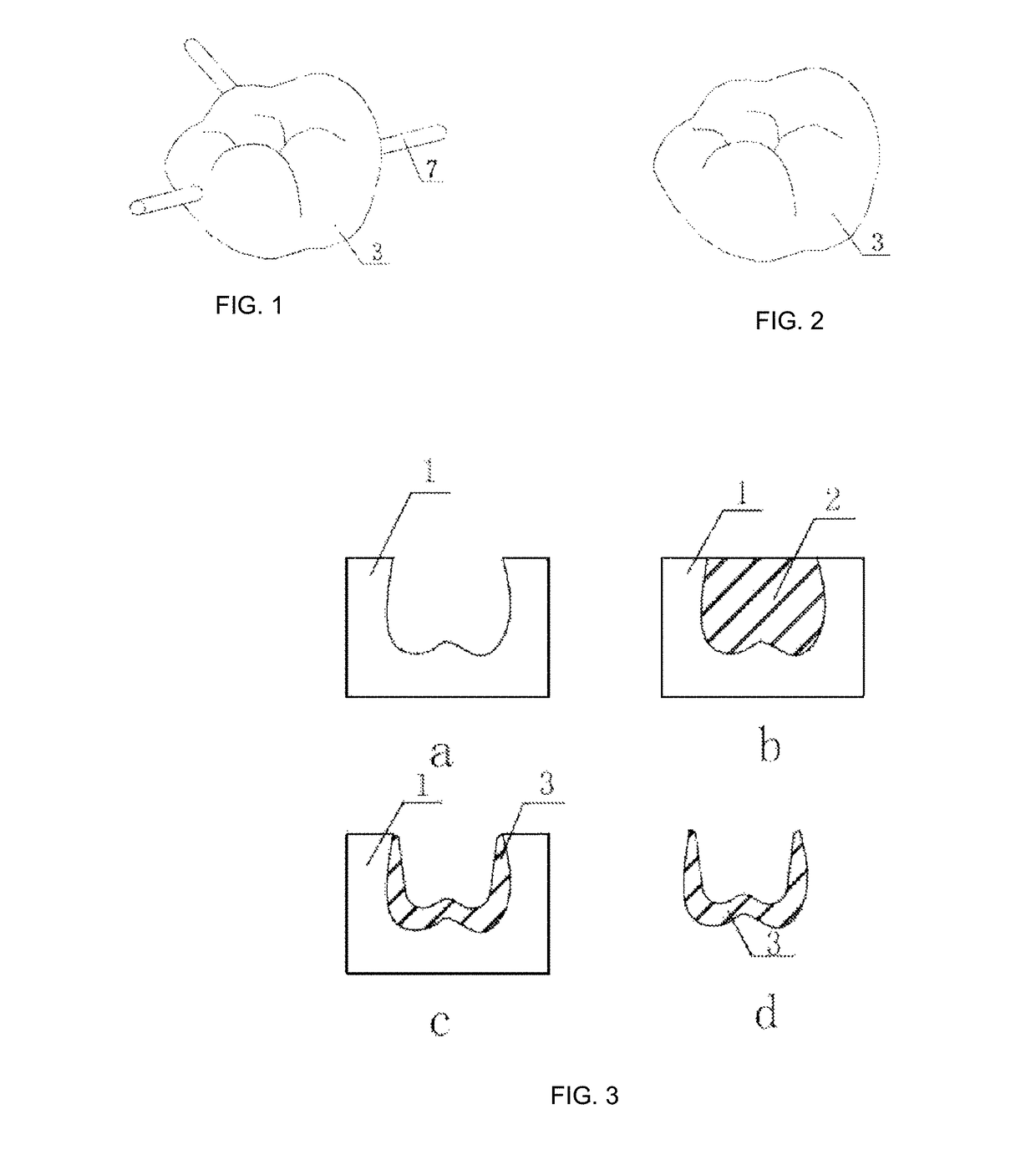

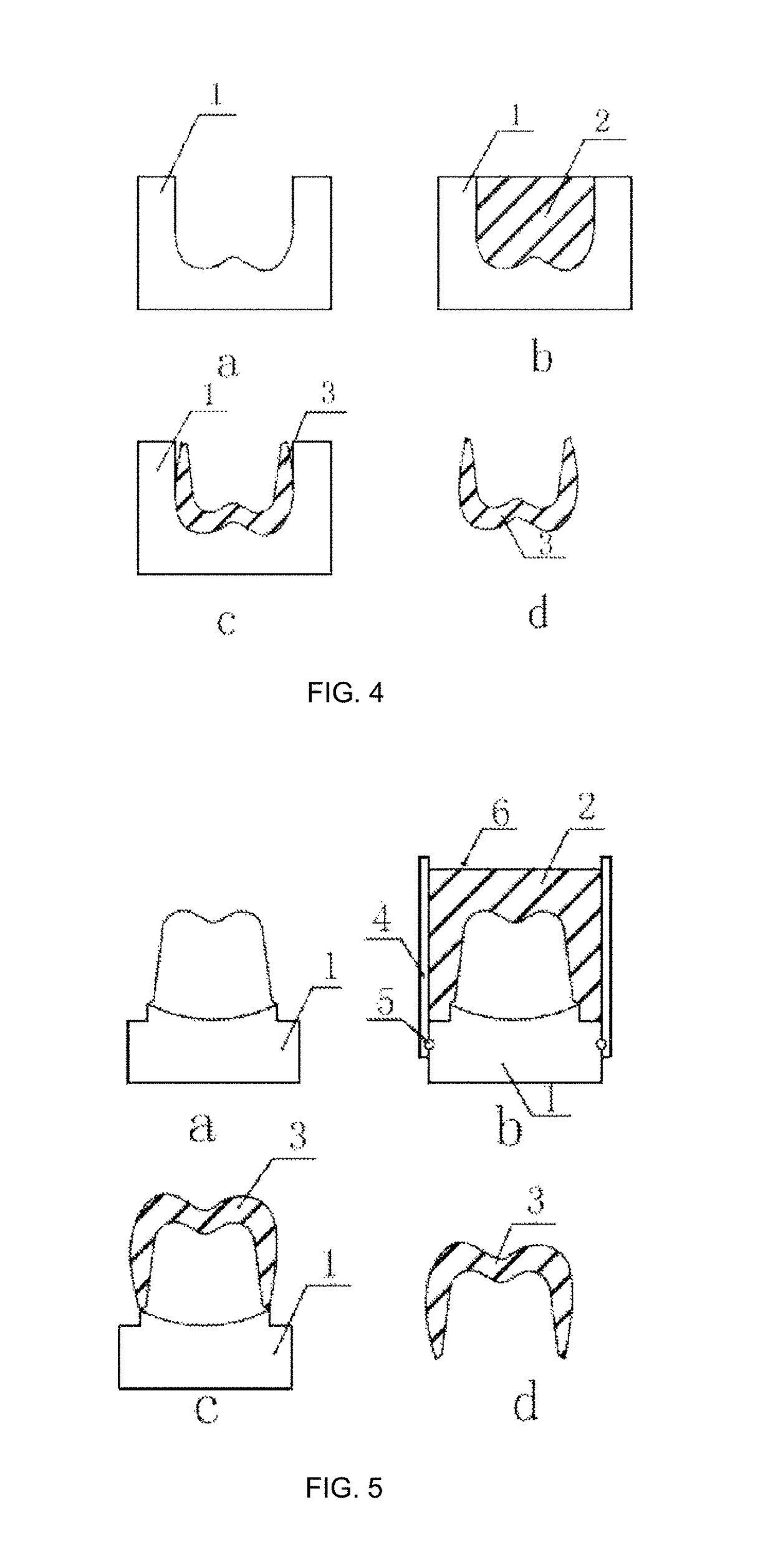

Dental all-ceramic restoration and manufacturing method thereof

ActiveUS20170231730A1Improve surface smoothnessIncrease success rateDental implantsImpression capsSurface finishParticle packing

A dental all-ceramic restoration and manufacturing method thereof; the outer surface of the dental all-ceramic restoration has neither visible marks remaining from the removal of the connecting bars (7) nor local grinding traces and chipping, and is smooth with uniform structure. The manufacturing method thereof is wet-forming or milling. No connecting bars are needed to connect the dental restoration bodies (3) with a surrounding mould blank or ceramic blank. This eliminates the need for manually cutting off the connecting bars (7) to separate the forming body from the surrounding ceramic blank, further grinding and polishing process to treat the excessively rough outer surface, and thereby reducing the risk of chipping and premature failure. In the manufacturing processes thereof, the hardened ceramic green body (2) made by wet-forming technique has more homogenous microstructure and less particle packing defects than the dry-pressed blanks and partially sintered blanks. Furthermore, higher surface smoothness can be obtained by milling unsintered hardened ceramic green body than by milling partially sintered blanks. The dental all-ceramic restoration has a high degree of surface finish, and can be directly used without polishing, veneering or glazing.

Owner:HANGZHOU ERRAN TECH

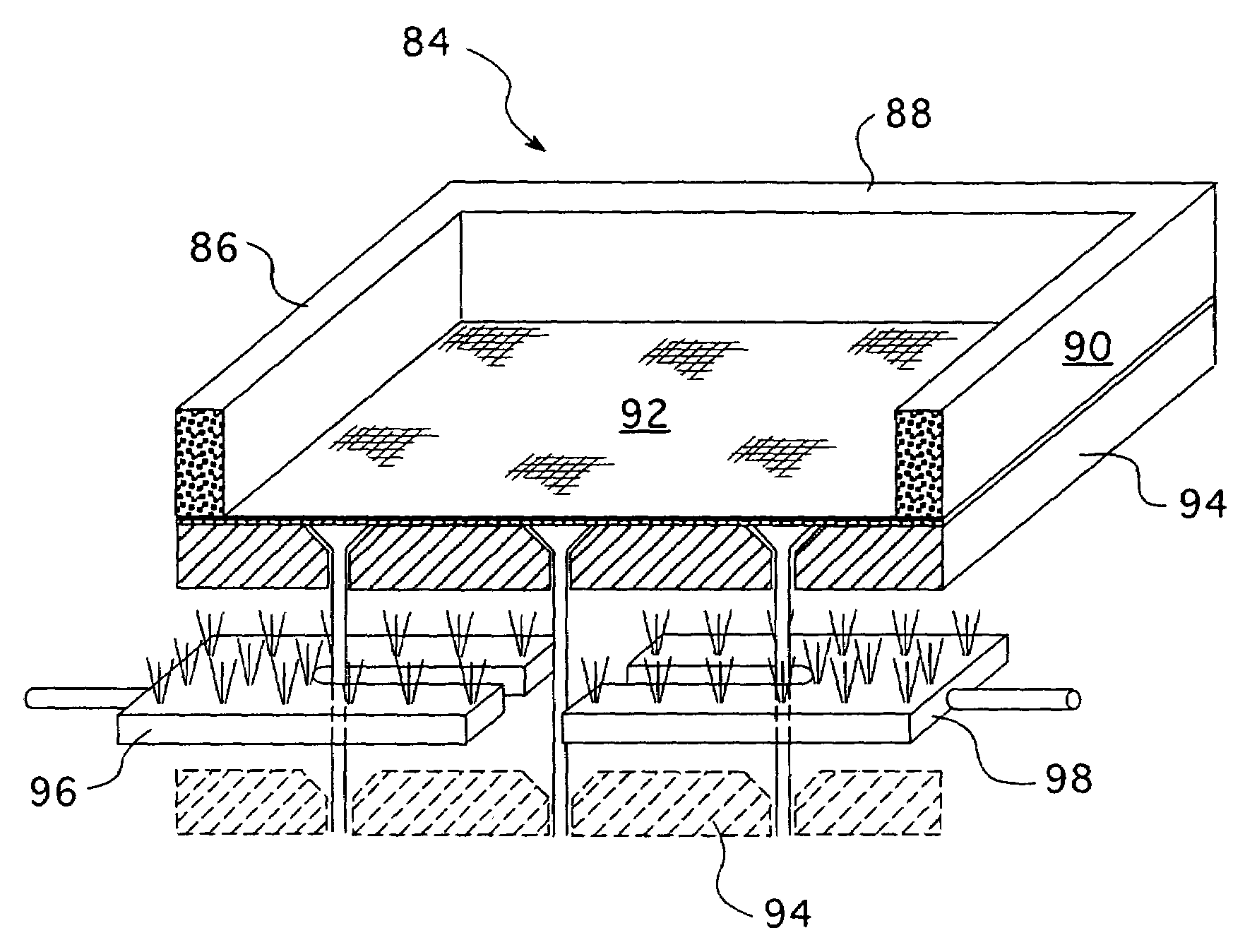

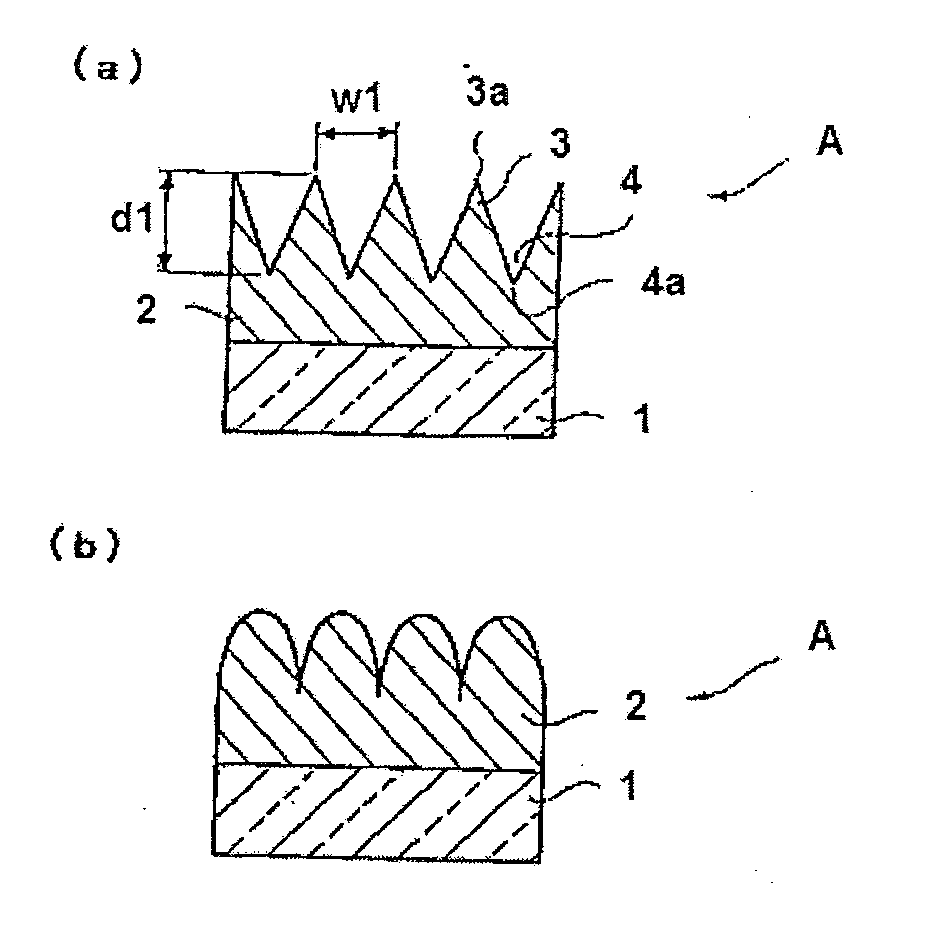

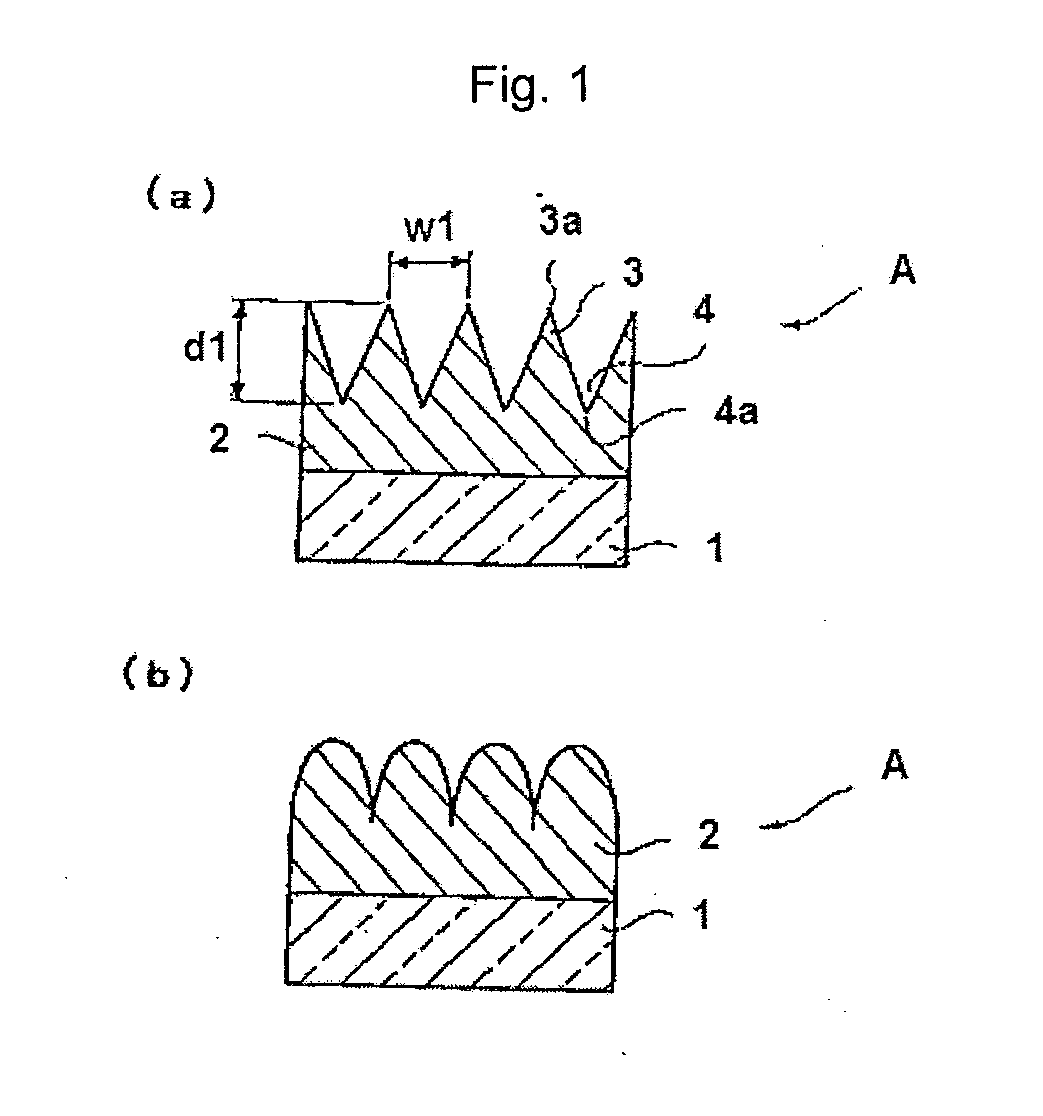

Active energy ray-curable resin composition, product having the uneven microstructure, and method for producing product having the uneven microstructure

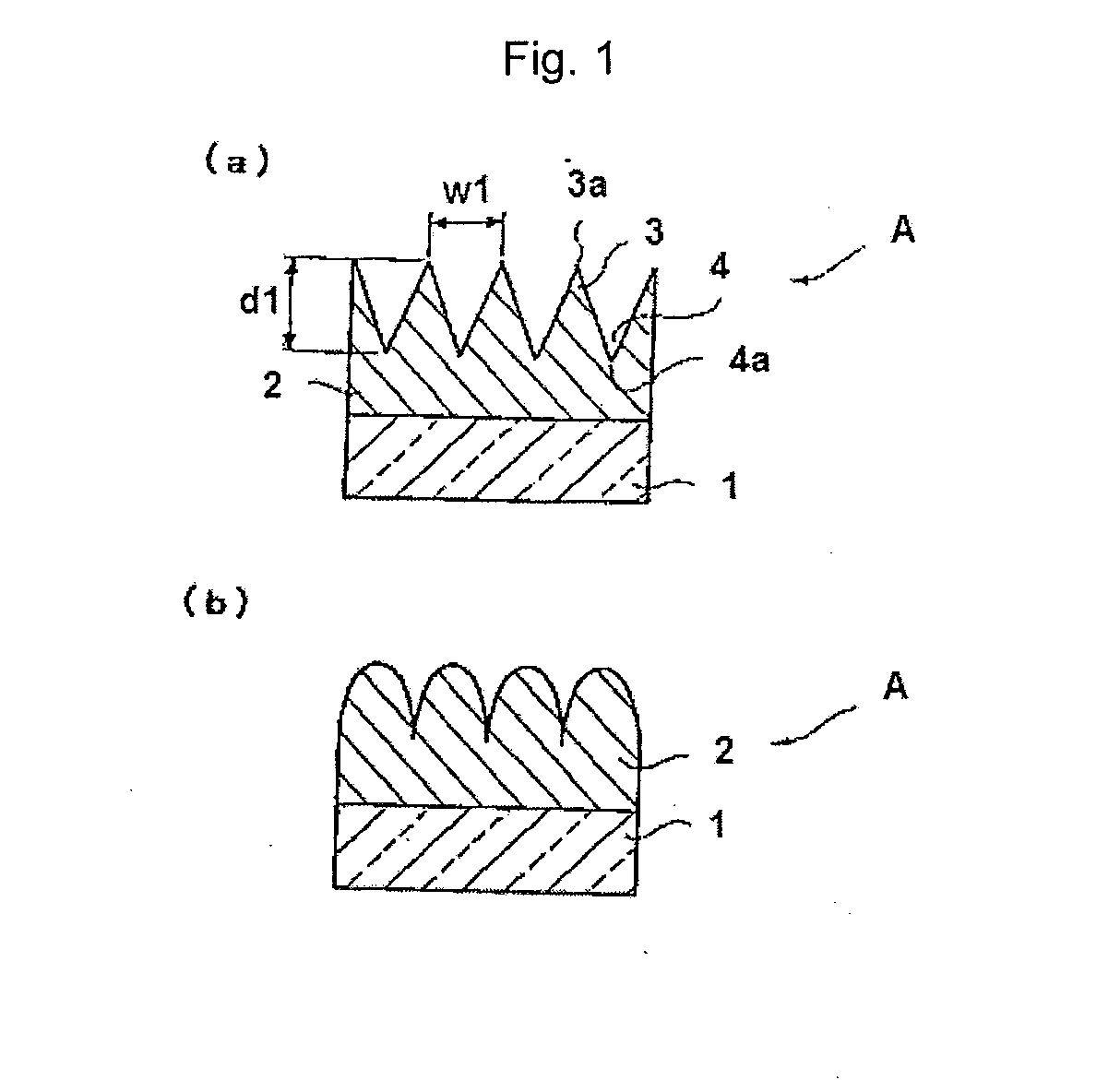

ActiveUS20130302564A1Improve scratch resistanceImprove anti-reflection effectFouling preventionLayered productsOrganic chemistryHomogeneous microstructure

The present invention provides an active energy ray-curable resin composition comprising at least a multifunctional monomer having three or more radical polymerizable functional groups in the molecule in which the cured product of the composition exhibits anti-reflective function because of an uneven microstructure formed on the surface of the cured product, and provides a product having the uneven microstructure having high decontaminating properties such as fingerprint removal properties and high scratch resistance.

Owner:MITSUBISHI CHEM CORP

Method of unidirectional solidification of castings and associated apparatus

InactiveUS7377304B2Simple methodConstant rateMelt-holding vesselsMolten metal pouring equipmentsMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

High purity niobium and products containing the same, and methods of making the same

InactiveUS6863750B2Fine grain structureUniform textureCellsElectrolytic capacitorsNiobiumUltimate tensile strength

High purity niobium metals and alloys containing the same are described. The niobium metal preferably has a purity of at least 99.99% and more preferably at least 99.999%. In addition, niobium metal and alloys thereof are described, which either have a grain size of about 150 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 30 random, or an incremental log ratio of (111):(100) intensity of greater than about −4.0, or any combination of these properties. Also described are articles and components made from the niobium metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity niobium metal which includes the step of reacting a salt-containing niobium and a metal salt along with at least one compound capable of reducing the salt-containing niobium to niobium and in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted niobium. The high purity niobium product preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

Creamy foodstuff and method for production thereof

InactiveUS20050013919A1Uniform microstructureMilk preparationFrozen sweetsBiopolymerContinuous mixing

The invention relates to a foodstuff having creamy to pasty characteristics comprising one or more biopolymers and water and having a homogeneous microstructure wherein the biopolymers are present in a very fine microscopic distribution and without discernible coarse clusters. This foodstuff is produced by mixing the constituents of the foodstuff to form a starting mixture of liquid to pasty consistency; cooling the starting mixture to a product temperature of below 0° C. with simultaneous continuous mixing and without aeration to produce a freeze-texturized homogenous mixture of the constituents of the foodstuff; and allowing the product temperature to rise to a distribution and consumption temperature of 4° C. and above.

Owner:NESTEC SA

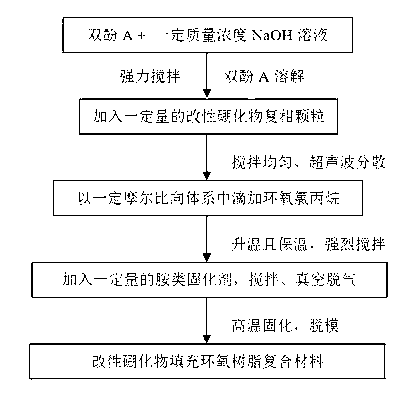

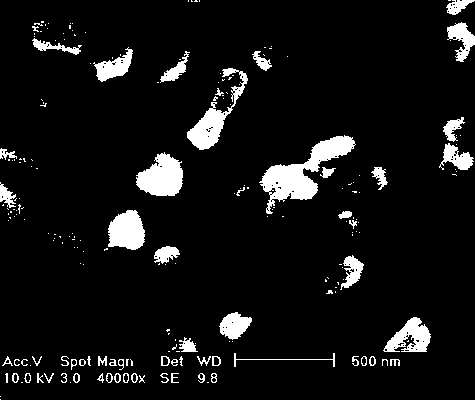

Composite material of modified boride filled with epoxy resin

The invention belongs to the technical field of high-performance composite materials, and specifically relates to a composite material of modified boride filled with epoxy resin, more specifically to a composite material which is obtained by modifying a high-performance ceramic powder surface by an organic functional group and filling organic resin and has homogeneous microstructure and excellent heat resistance and wear resistance. Through an in situ polymerization method for preparation, bisphenol A is firstly dissolved in a NaOH solution completely, the boride powder with the surface modified by the organic functional group is added, ultrasonic oscillation and intense agitation for dispersion are carried out, chloropropylene oxide is then added for polymerization, a curing agent is added, and curing molding is carried out at a high temperature. The prepared composite material of modified boride filled with epoxy resin has structural features of homogeneous material microstructure and excellent heat resistance and wear resistance, and can be applied in high-temperature wear-resistant members required in the industrial fields of aviation, automobile and the like.

Owner:FUDAN UNIV

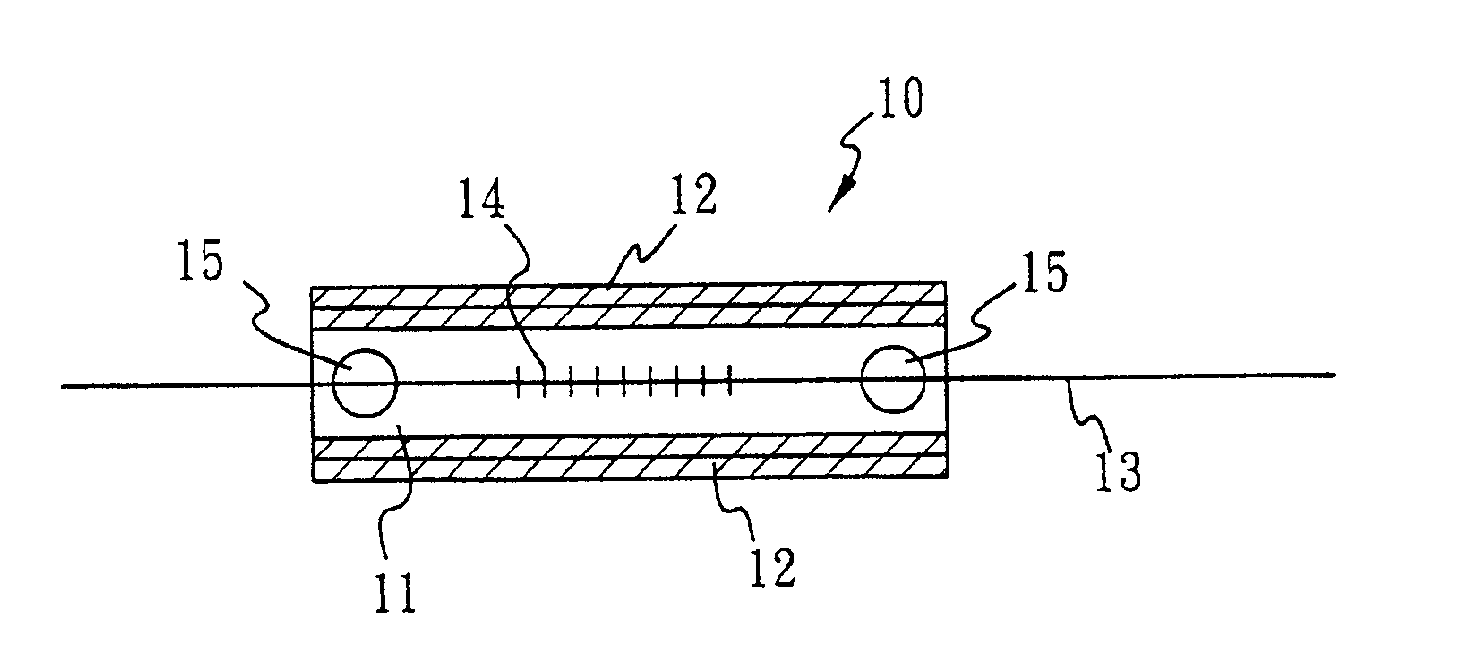

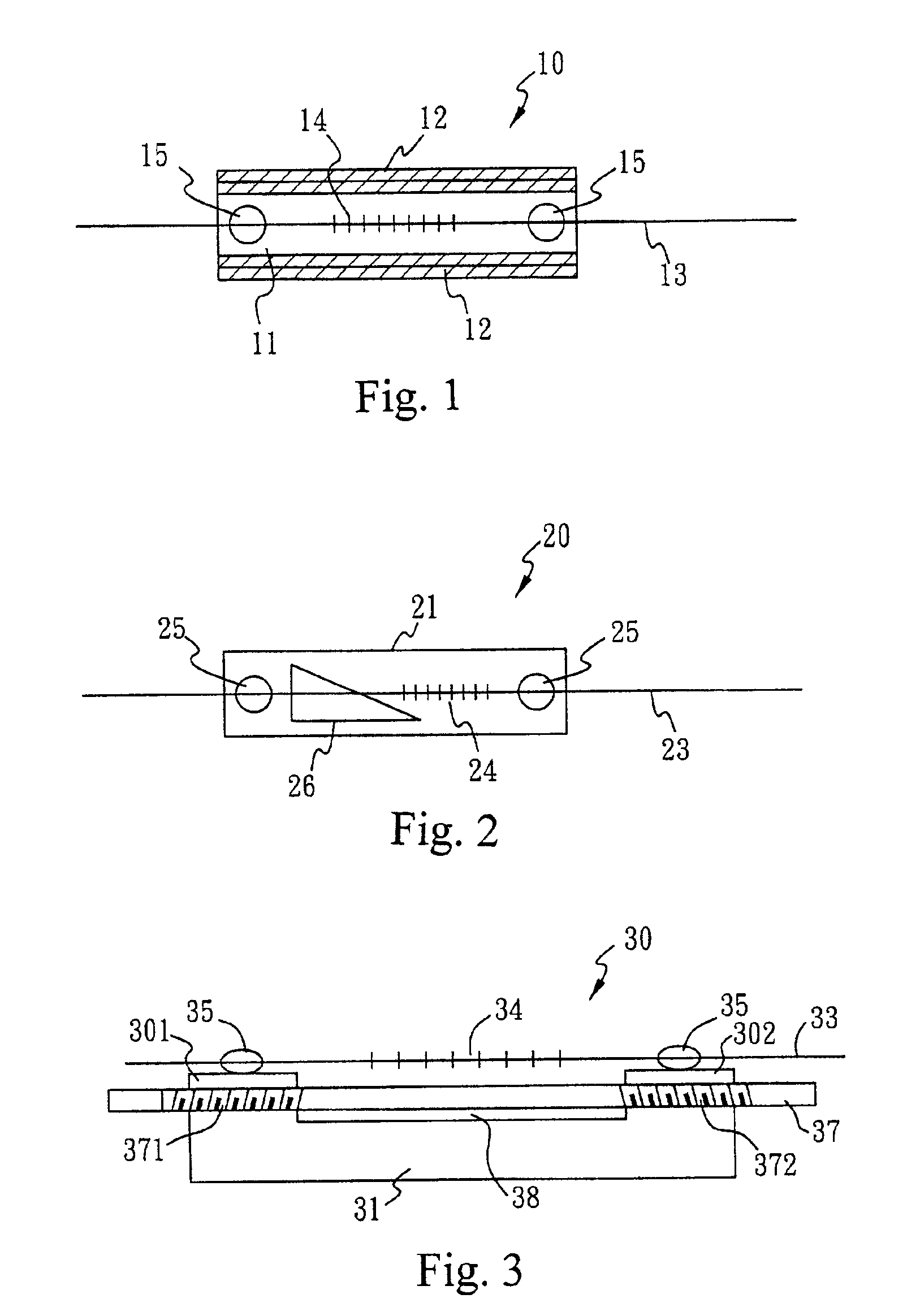

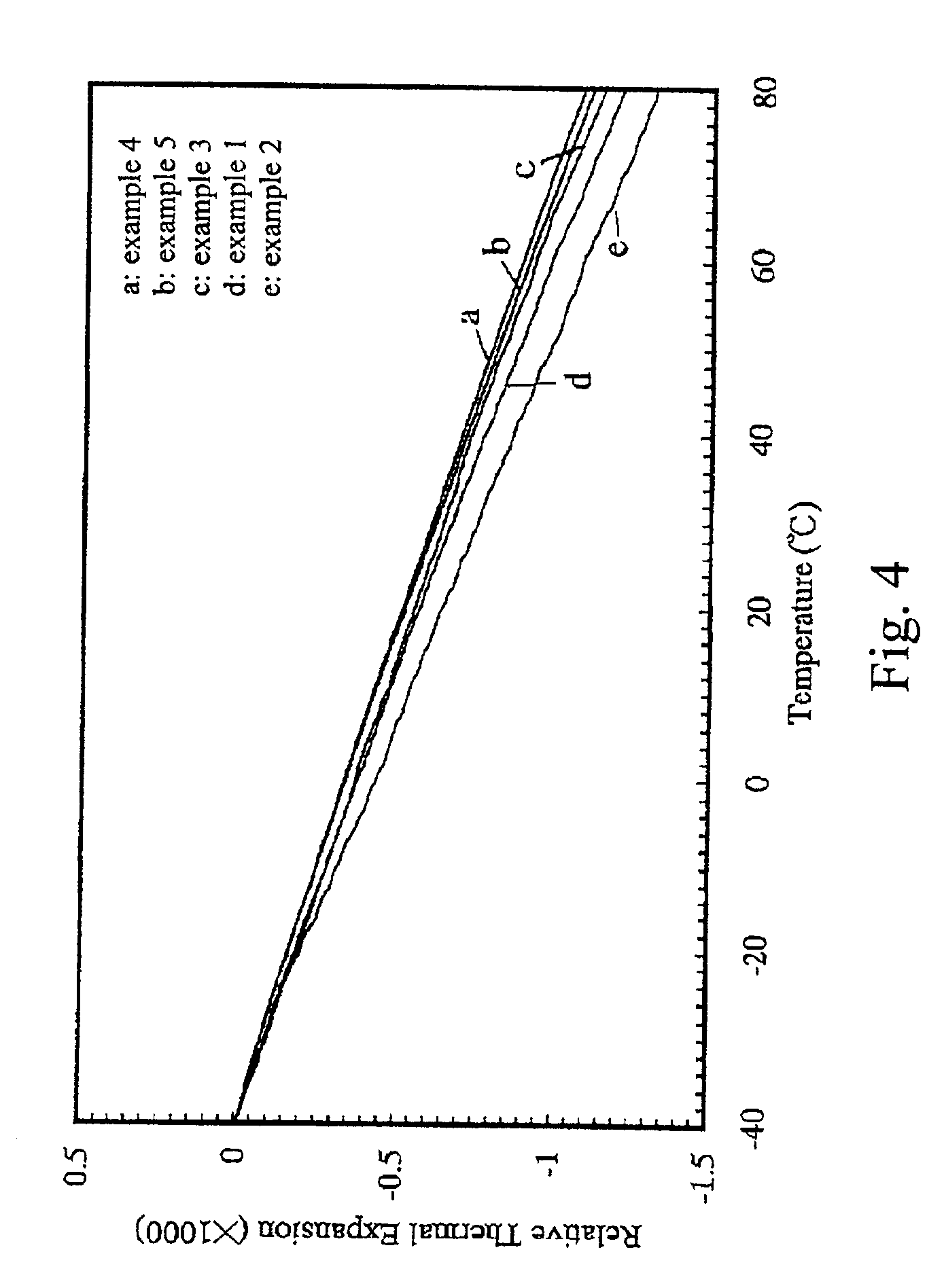

Process for preparation of zirconium tungstate ceramic body, zirconium tungstate ceramic body prepared thereby, and temperature compensated fiber bragg grating device

InactiveUS6936235B2Uniform microstructureSimple procedureCladded optical fibreTungsten oxides/hydroxidesFiberGrating

The present invention discloses a process for the preparation of zirconium tungstate (ZrW2O8) ceramic body, comprising a reactive sintering step to react and sinter powders of the raw materials comprising a Zr-containing compound and a W-containing compound to form a zirconium tungstate ceramic body. The addition of zirconium tungstate powders as the seeds in the process can effectively reduce the steps, shorten the preparation time, lower the sintering temperature and duration, save the cost, and provide the zirconium tungstate ceramic body with uniform microstructure. Also, a process for the preparation of modified zirconium tungstate ceramic body is disclosed, by forming a second phase in the zirconium tungstate ceramic body to tune the thermal expansion coefficient of the zirconium tungstate ceramic body. The present invention also relates to the use of the modified zirconium tungstate ceramic body to provide a temperature compensated fiber bragg grating (FBG) device.

Owner:BROPTICS TECHNOLOGY LTD

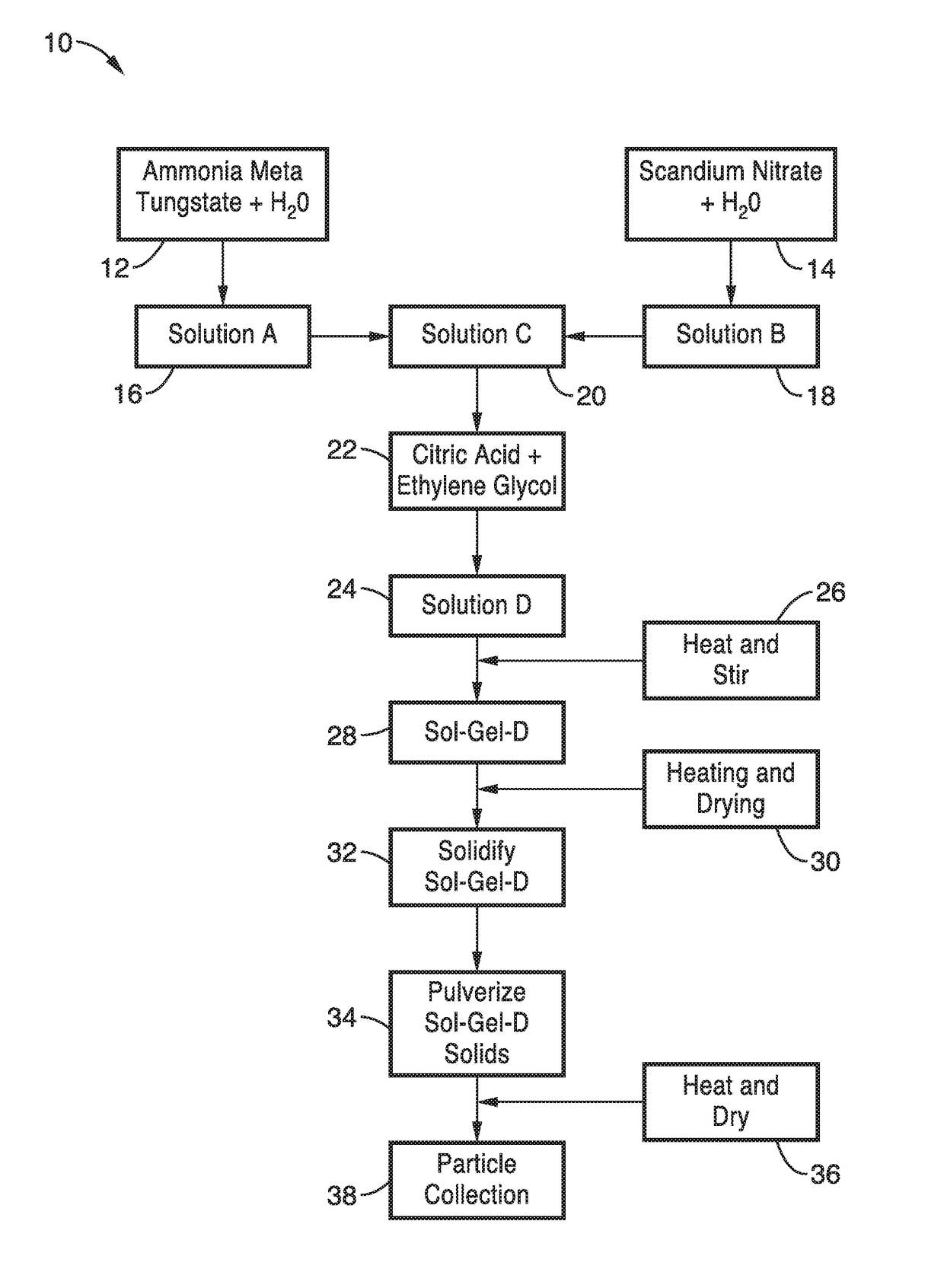

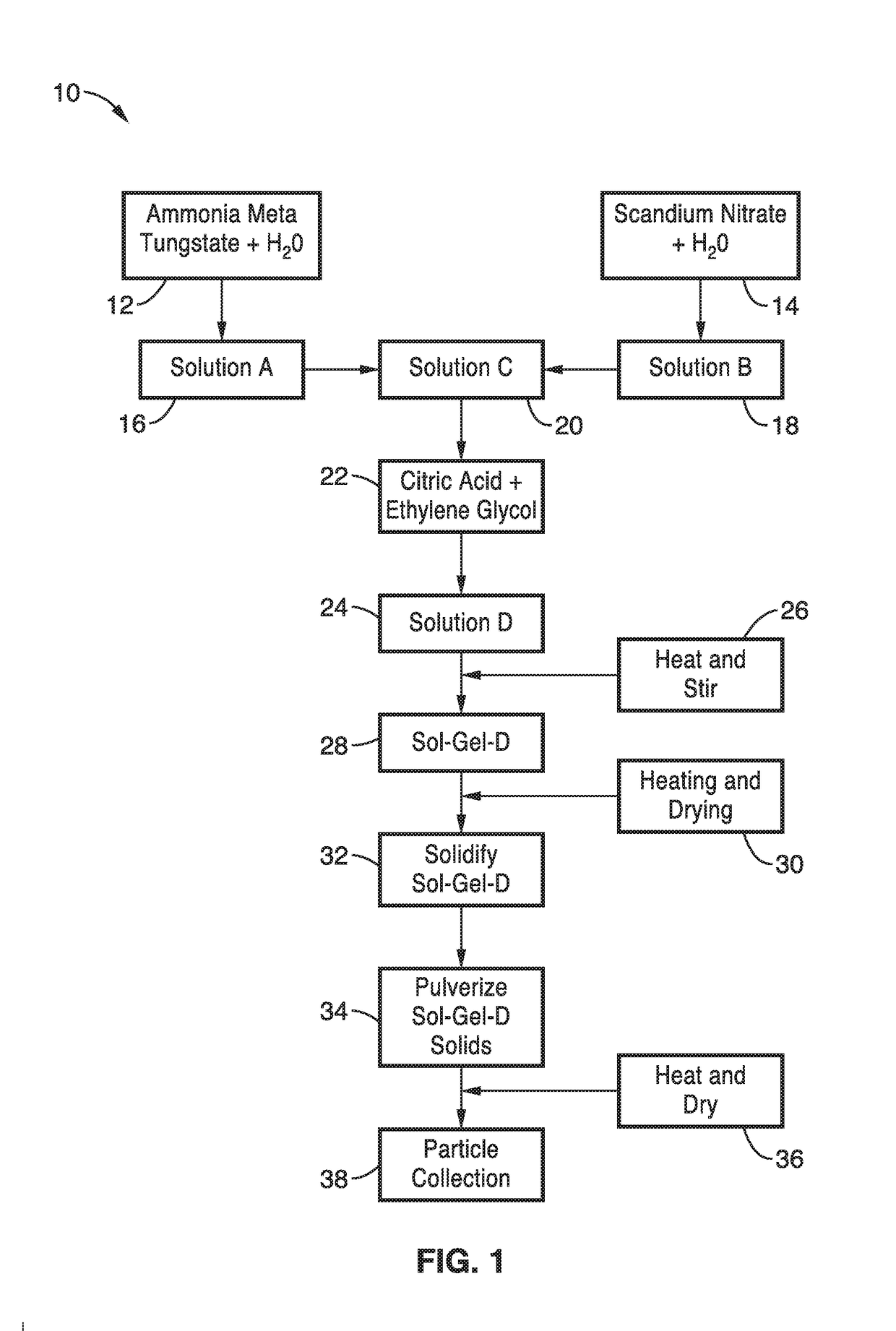

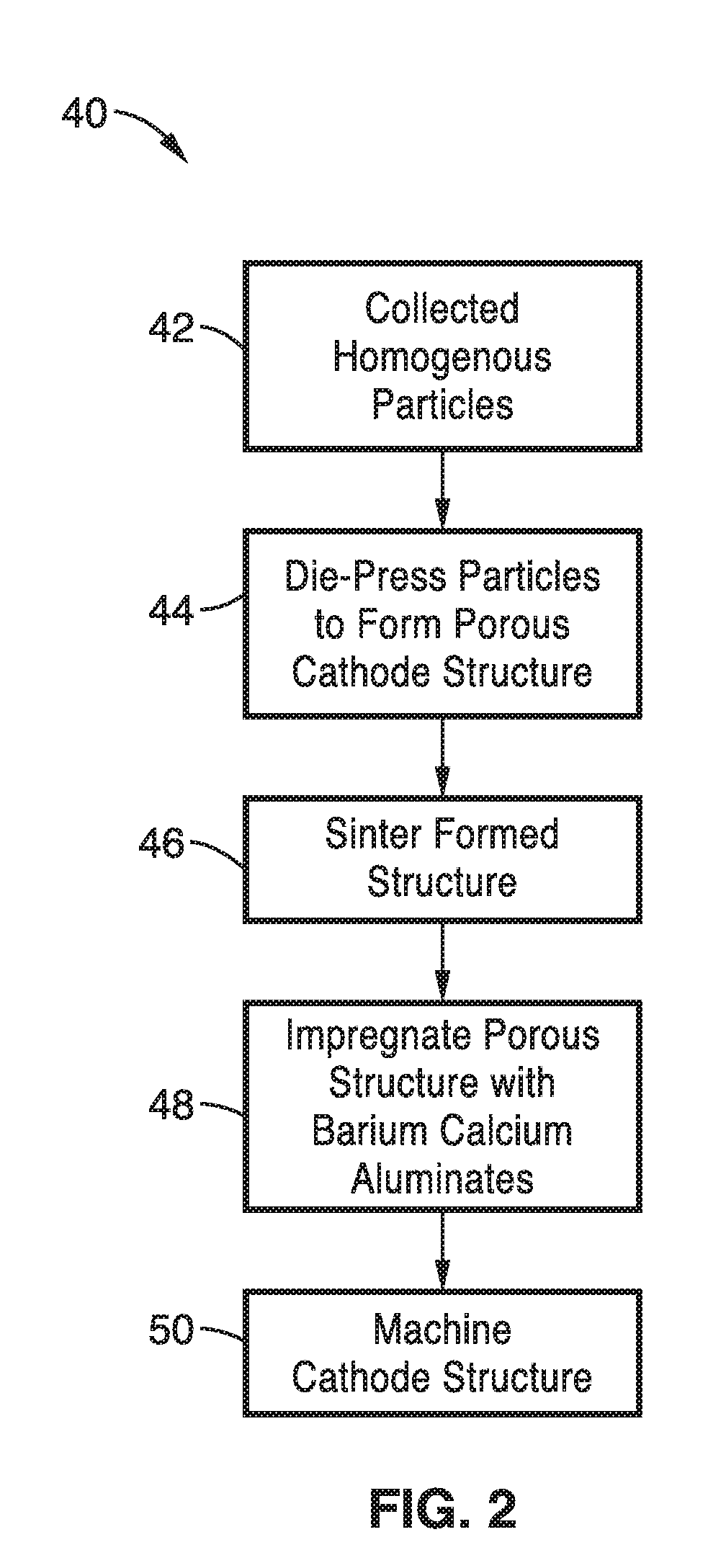

Method of fabricating tungsten scandate nano-composite powder for cathodes

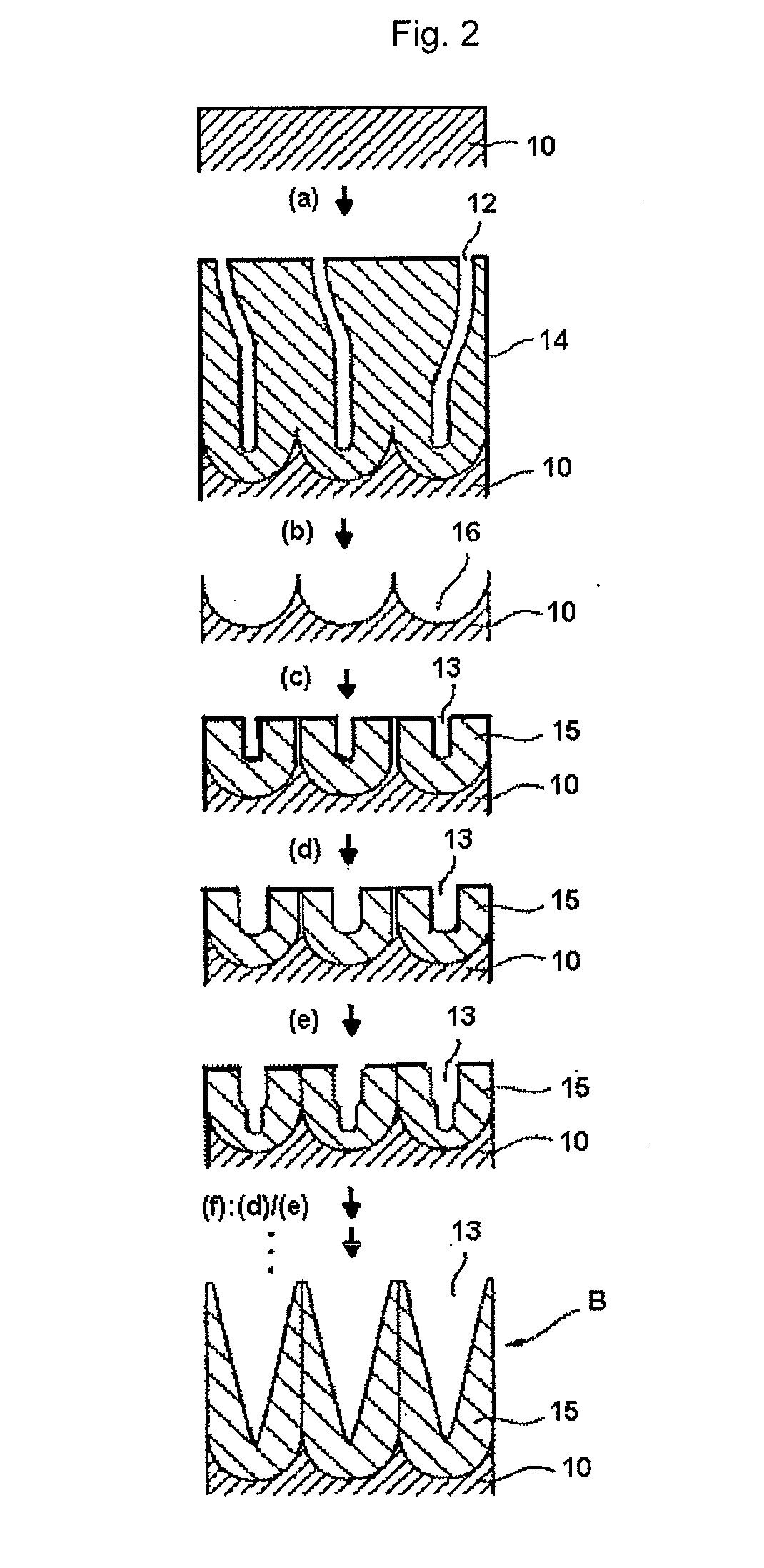

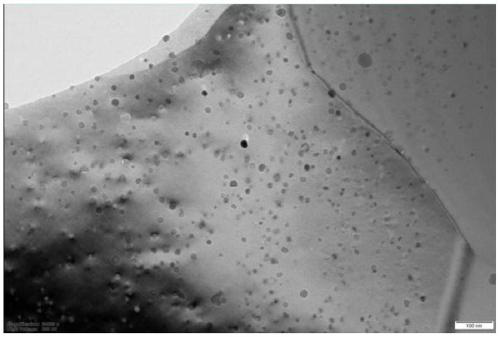

ActiveUS20170358419A1High porosityNarrow distributionDischarge tube/lamp detailsThermionic cathode manufactureHigh current densityParticle composition

Methods for fabricating refractory metal scandate nanocomposite powders with homogeneous microstructured refractory metal grains and a uniform nanosized dispersion of scandia are provided. The powders prepared by the sol-gel methods have a spherical morphology, a narrow distribution of particle sizes and a very uniform dispersion of nanosized scandia particles joined to the tungsten grains. The powder particle sizes can range from nanometers to micrometers. The powders can be pressed into porous cathode structures that can be impregnated with emissive materials to produce high current density and long life cathodes for high-power terahertz vacuum electron devices. The sol-gel fabrication methods allow control over the materials, particle size, particle composition and pore size and distribution of the cathode structure by manipulation of the process parameters.

Owner:RGT UNIV OF CALIFORNIA

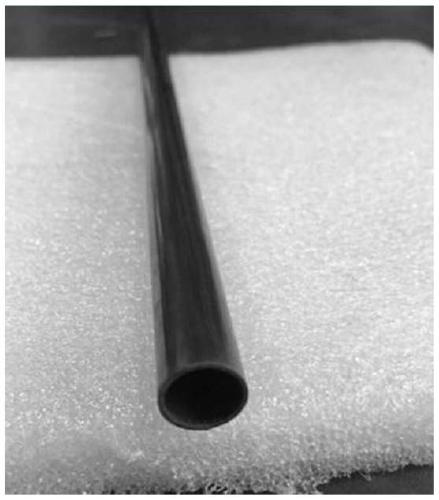

Preparation method for oxide dispersion strengthened FeCrAl alloy pipe

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

Preparation method for resin binder and diamond grinding tool with homogeneous microstructure

InactiveCN109202753AEasy chip removalConducive to debrisAbrasion apparatusGrinding devicesMicrosphereSharpening

The invention discloses a preparation method for a resin binder and diamond grinding tool with a homogeneous microstructure and belongs to the technical field of abrasives, grinding tools and grinding. The preparation method comprises the main steps that a resin binder and a diamond abrasive are treated with surfactant and then are mixed, and then the mixture is mixed with glass hollow microspheres or ceramic hollow spheres evenly coated with a layer of coal ash; filler is put in; die filling is conducted, and hot press molding is adopted; and finally with-die solidification is conducted, andthe resin binder and diamond grinding tool with the homogeneous microstructure is obtained. The preparation method has the beneficial effects that the grinding tool is provided with homogeneous air holes, and chip removal and chip holding are facilitated for the grinding tool; and the grinding tool is high in holding force, good in sharpness and high in grinding efficiency and has a good blade sharpening effect, and workpiece surface machining precision is high.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Hydraulic engineering anti-cracking concrete and preparation method thereof

InactiveCN107021702AHarmful Porosity ReductionImprove compactnessSolid waste managementFiberPorosity

The invention relates to hydraulic engineering anti-cracking concrete and a preparation method thereof, and relates to the field of durability of concrete. The hydraulic engineering anti-cracking concrete is prepared from the following raw materials in percentage by weight: 9.5 to 13.5 percent of P.O42.5 cement, 40 to 50 percent of cobblestone, 25.5 to 30 percent of region II medium sand, 5 to 15 percent of mineral admixture, 0.1 to 0.15 percent of nano mineral fiber, 0.009 to 0.075 percent of an air entraining agent, and 6.5 to 8 percent of water. The hydraulic engineering anti-cracking concrete has the beneficial effects that all components form a uniform microscopic structure by closest packing of concrete, the deleterious porosity in the concrete is reduced, the compactness of the concrete is increased, and the durability of the concrete is improved; the adopted nano mineral fibers belong to natural clay minerals, the storage quantity is large, and the nano mineral fibers are easily obtained; the water absorbing capacity in the concrete is strong, more space is easily provided for cement hydration, the pore structure of the concrete can be refined, the tensile capacity of the concrete is increased, and the early shrinkage of the concrete is reduced; moreover, compared with common concrete, the raw materials adopted in the hydraulic engineering anti-cracking concrete are low in cost and convenient to transport, thereby greatly improving the economical efficiency.

Owner:STATE GRID CORP OF CHINA +3

Active energy ray-curable resin composition, product having the uneven microstructure, and method for producing product having the uneven microstructure

ActiveUS20140314993A1Improve scratch resistanceImprove anti-reflection effectFouling preventionLayered productsOrganic chemistryHomogeneous microstructure

The present invention provides an active energy ray-curable resin composition comprising at least a multifunctional monomer having three or more radical polymerizable functional groups in the molecule in which the cured product of the composition exhibits anti-reflective function because of an uneven microstructure formed on the surface of the cured product, and provides a product having the uneven microstructure having high decontaminating properties such as fingerprint removal properties and high scratch resistance.

Owner:MITSUBISHI CHEM CORP

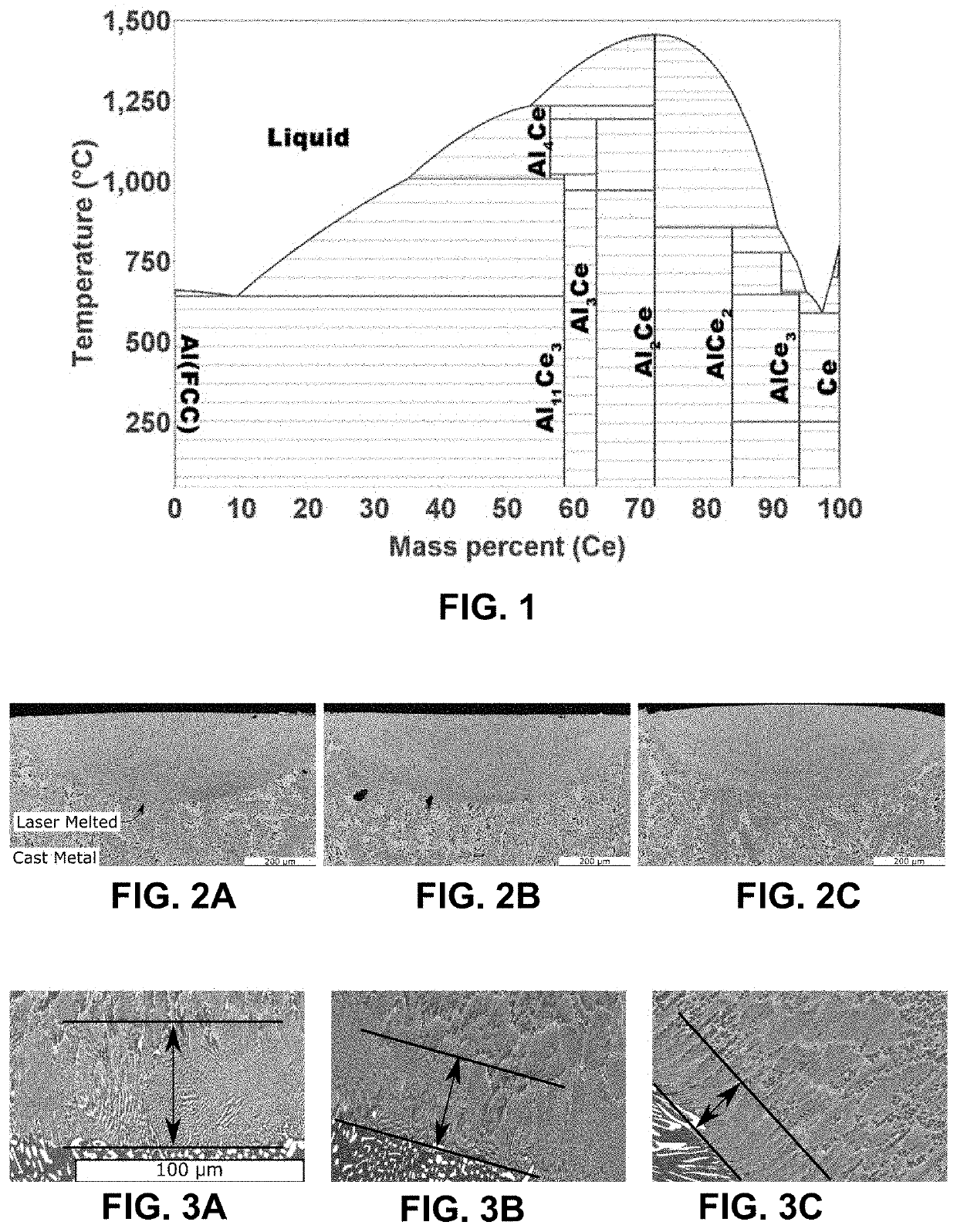

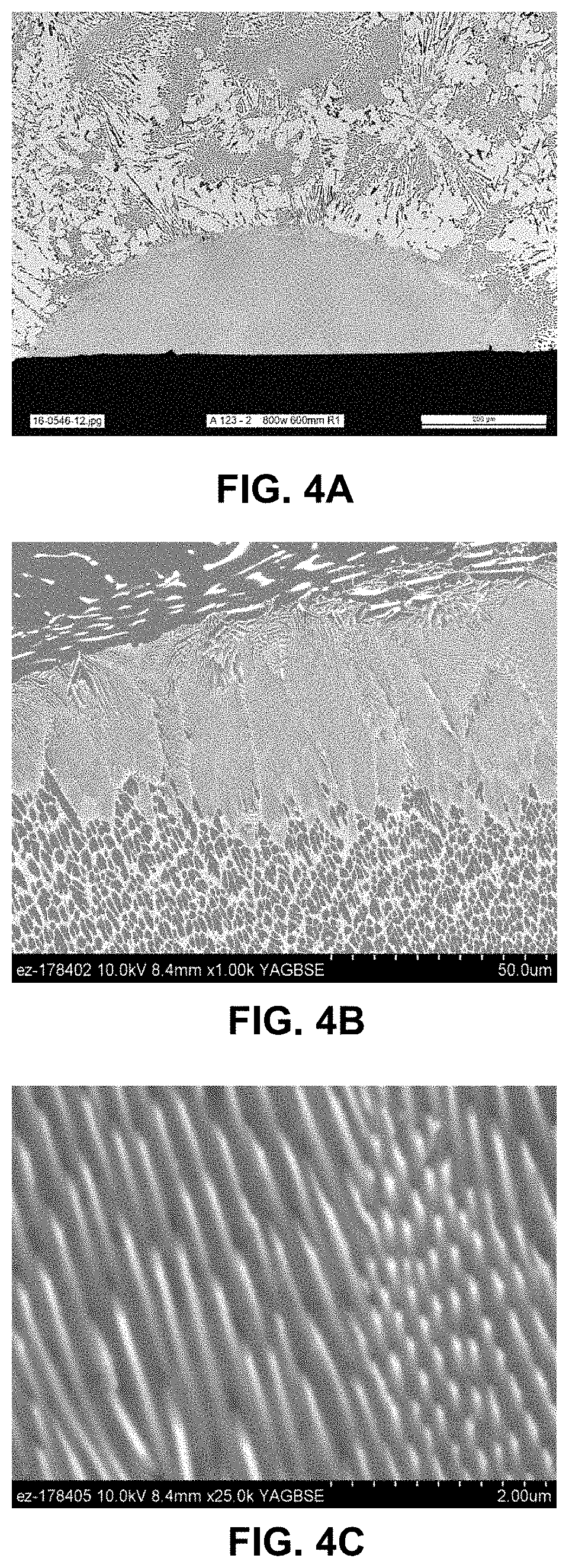

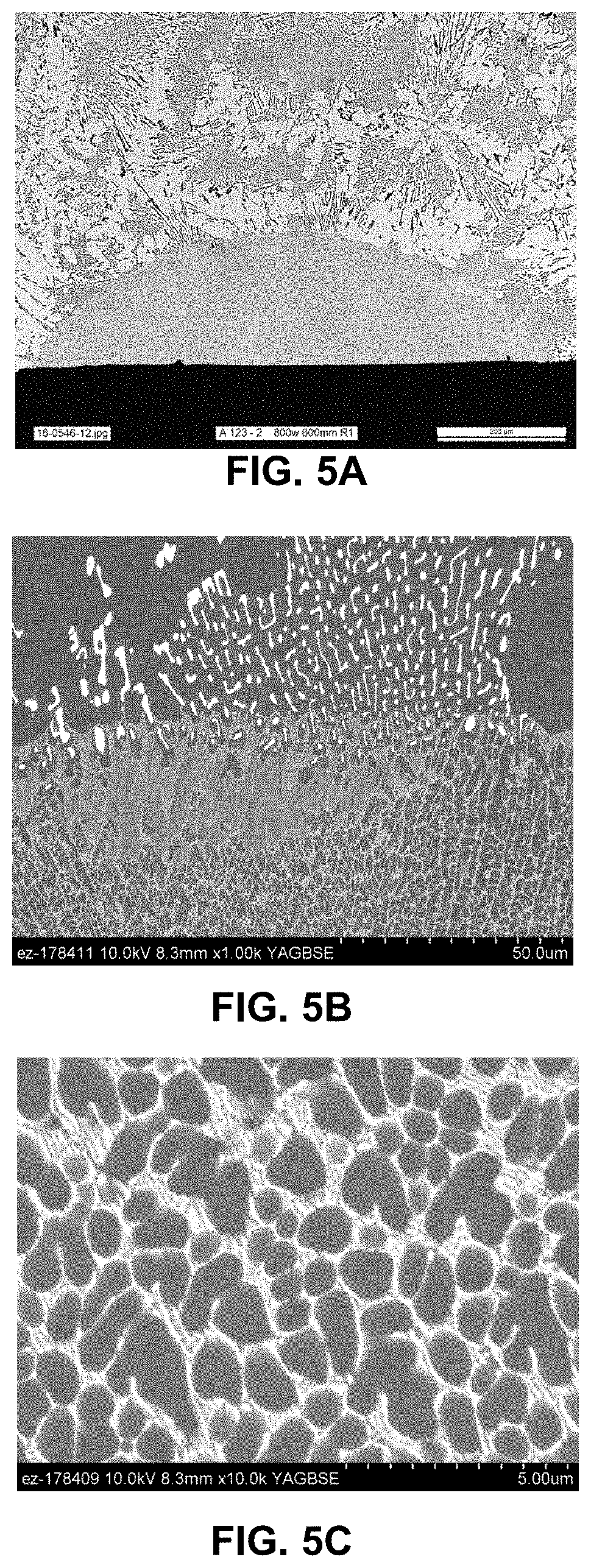

Additive manufacturing methods using aluminum-rare earth alloys and products made using such methods

ActiveUS10760148B2Additive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strengthHomogeneous microstructure

Described herein are additive manufacturing methods and products made using such methods. The alloy compositions described herein are specifically selected for the additive manufacturing methods and provide products that exhibit superior mechanical properties as compared to their cast counterparts. Using the compositions and methods described herein, products that do not exhibit substantial coarsening, such as at elevated temperatures, can be obtained. The products further exhibit uniform microstructures along the print axis, thus contributing to improved strength and performance. Additives also can be used in the alloys described herein.

Owner:UT BATTELLE LLC +3

Graphene/silicon carbide composite material and preparation method thereof

InactiveCN108751175AUniform microstructureHomogeneous isotropicGrapheneNanotechnologyNano siliconDistilled water

The invention aims to solve the problem existing in the prior art to prepare a graphene coated silicon carbide composite material, provides a graphene / silicon carbide composite material and a preparation method thereof, and belongs to the technical field of graphene composite materials. The method comprises the steps that laminated graphite with the appropriate size is appropriately mixed with nano silicon carbide particle powder, ethyl alcohol and distilled water are added to serve as a grinding medium and a process control reagent, sufficiently ball milling is conducted for a certain periodof time, and the nano composite material with a graphene coated silicon carbide core-shell structure is prepared. Graphene does not need to be prepared firstly, and preparation of the graphene / siliconcarbide composite material is completed under the ball milling condition. In addition, no dangerous reagents is used in the preparation process, and no high temperature and high pressure process exists. The prepared product has the more uniform microstructure and the isotropous performance.

Owner:UNIV OF SCI & TECH LIAONING

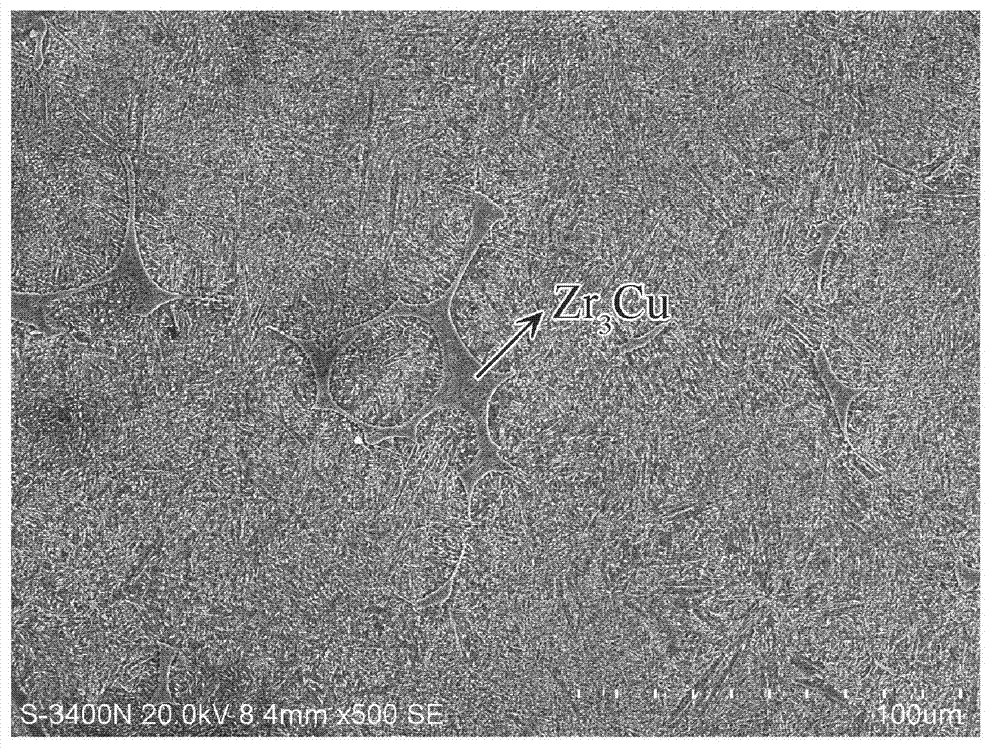

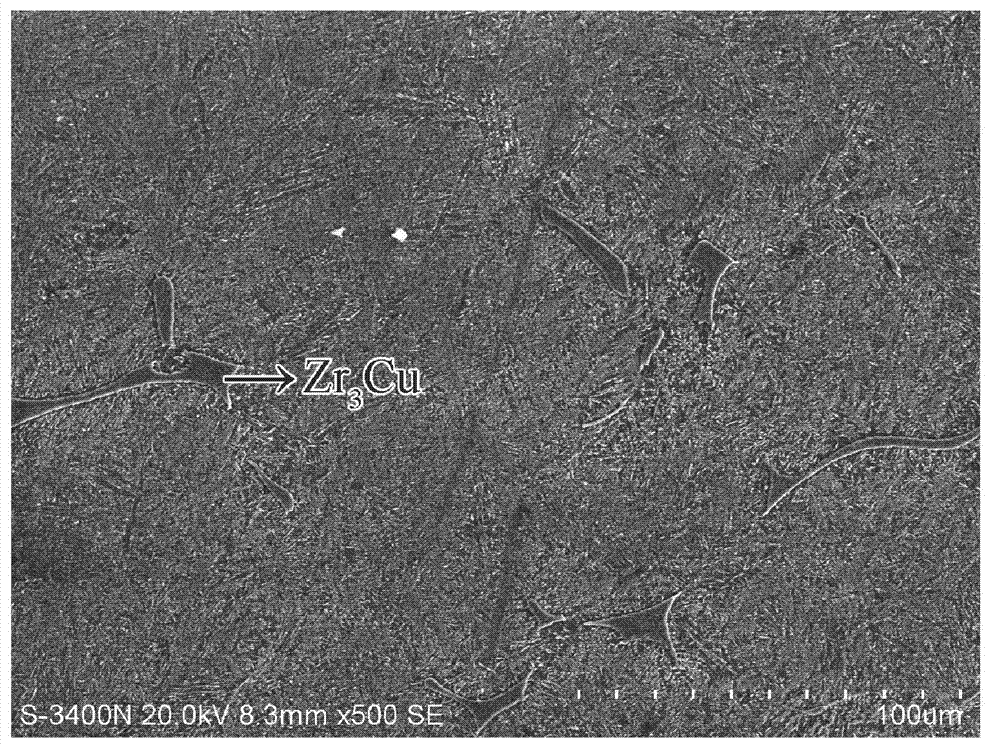

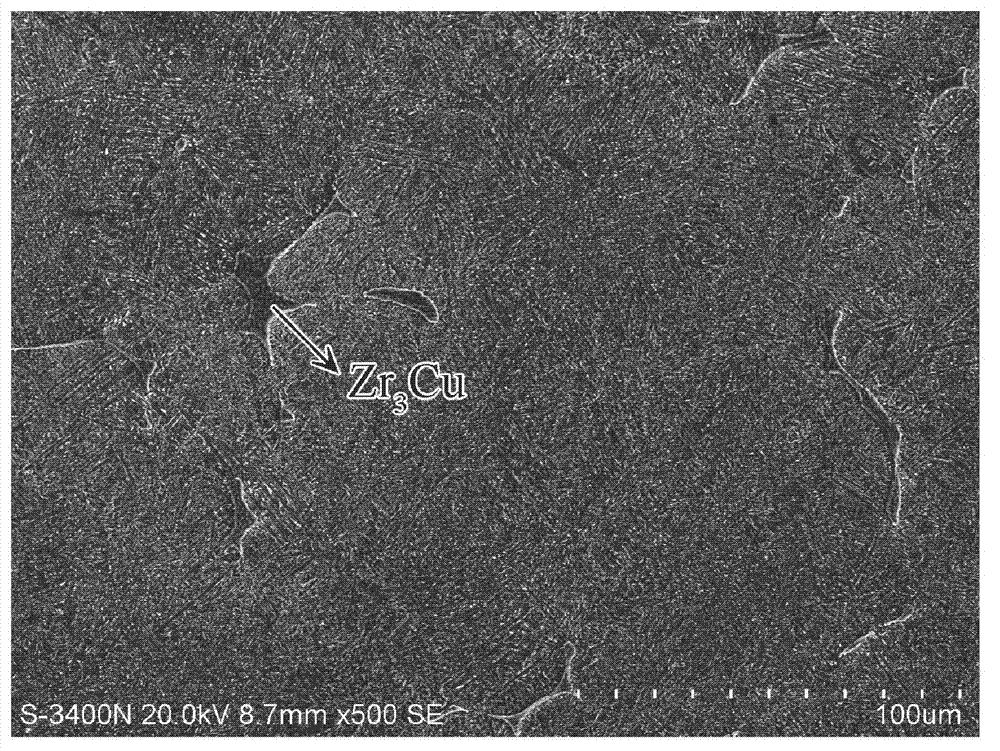

Hard-tissue bio-medical in-situ synthesized zirconium matrix composite material and preparation method thereof

The invention discloses a hard-tissue bio-medical in-situ synthesized zirconium matrix composite material and a preparation method thereof. The hard-tissue bio-medical in-situ synthesized zirconium matrix composite material comprises the following components by weight percent: 3.5-4.5 percent of copper, 0.1-1.20 percent of niobium and the balance of zirconium sponge. According to the preparation method, the raw materials are weighed according to the weight percents of the components, mixed fully, then smelted by using a non-consumable vacuum arc smelting furnace, and cooled to obtain metal ingots with a homogeneous microstructure. The hard-tissue bio-medical in-situ synthesized zirconium matrix composite material has the advantages of traditional medical titanium alloy, and simultaneously solves the problem that the young's modulus of the traditional medical titanium alloy does not match with the natural bones of the human body as well as the problem of damage to human bodies caused by the mismatching mechanical performance of substitute materials; according to the hard-tissue bio-medical in-situ synthesized zirconium matrix composite material and the preparation method thereof, zirconium matrix is strengthened by using in-situ synthesized Zr3Cu as the reinforcing phase and niobium as the alloying element, the compression strength of the zirconium matrix composite material is effectively improved, and meanwhile the compression strength, the plasticity, the young's modulus and the like of the zirconium matrix composite material are changed by adjusting the content of niobium.

Owner:GUANGXI UNIV

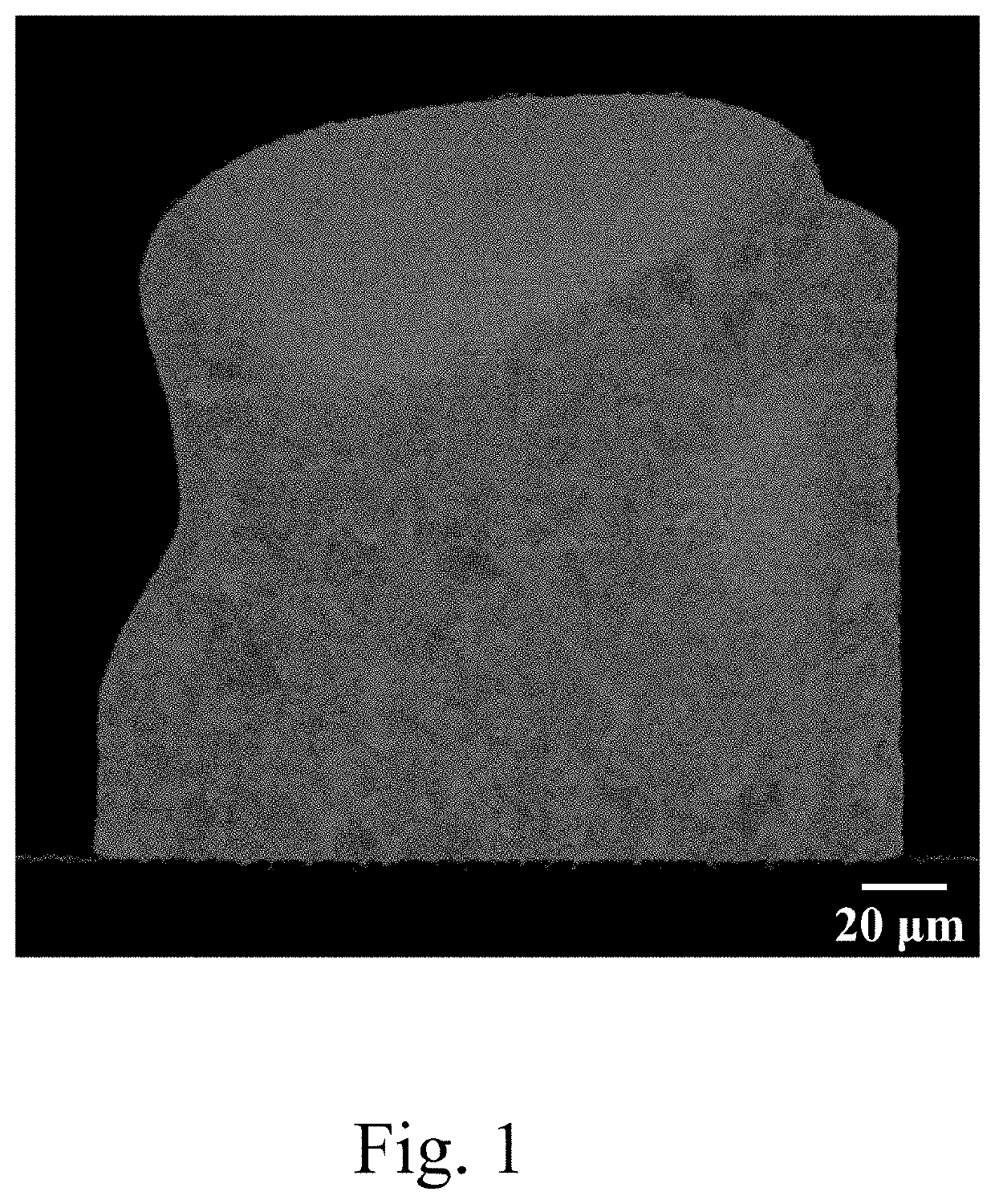

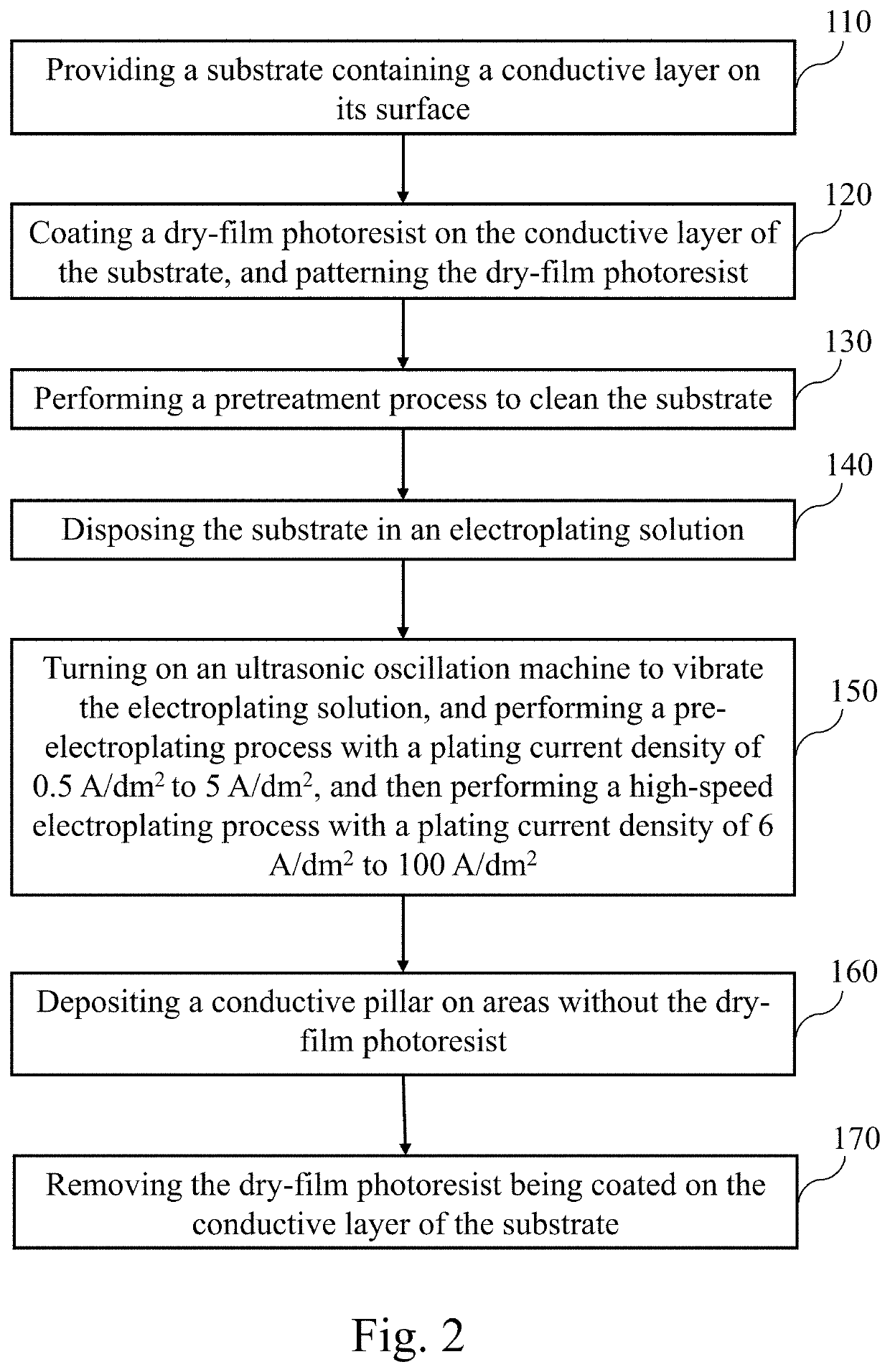

High-speed electroplating method

A high-speed electroplating method is provided. The high-speed electroplating method includes the following steps: providing a substrate containing a conductive layer on its surface; coating a dry-film photoresist on the conductive layer of the substrate, and patterning the dry-film photoresist; performing a pretreatment process to clean the substrate; disposing the substrate in an electroplating solution; turning on an ultrasonic oscillation machine to vibrate the electroplating solution, and turning on a jet flow device to agitate the electroplating solution, and performing a pre-electroplating process with a plating current density of 0.5 A / dm2 to 5 A / dm2, and then performing a high-speed electroplating process with a plating current density of 6 A / dm2 to 100 A / dm2; depositing a conductive pillar on areas without the dry-film photoresist; and removing the dry-film photoresist being coated on the conductive layer of the substrate. Thus, the high-speed electroplating method can achieve high-speed electrodeposition with uniform microstructures.

Owner:YUAN ZE UNIV

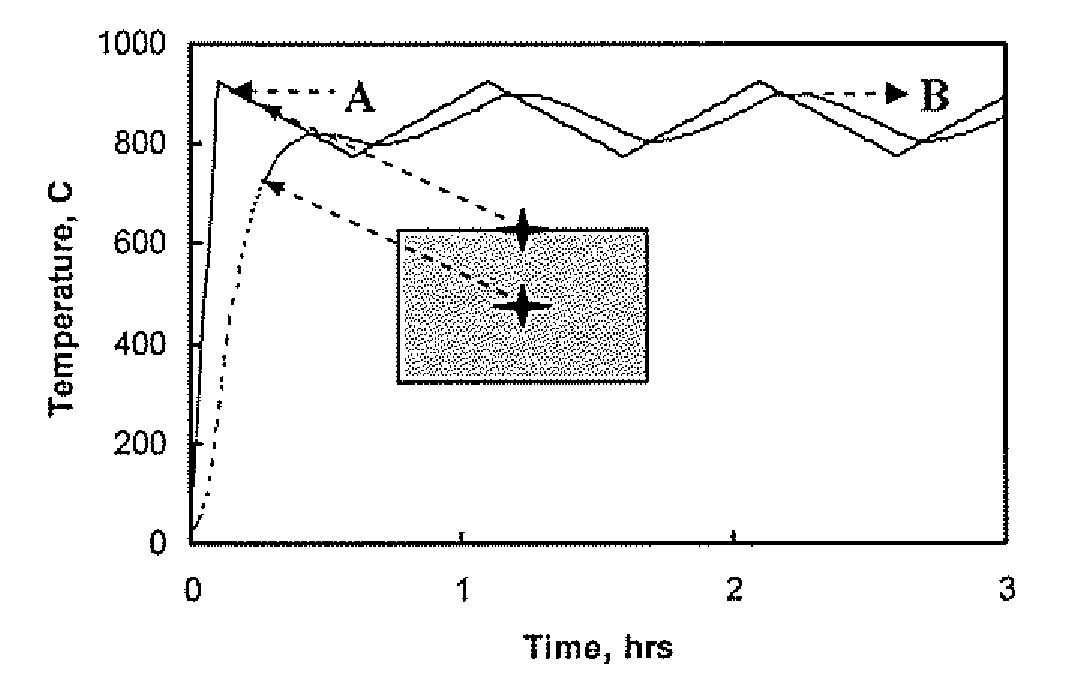

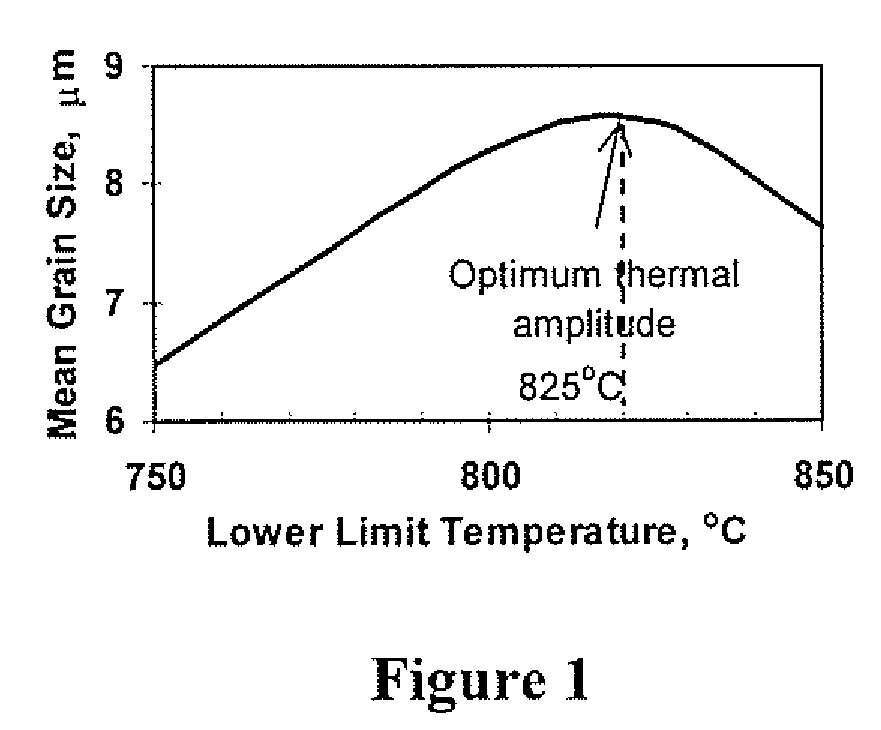

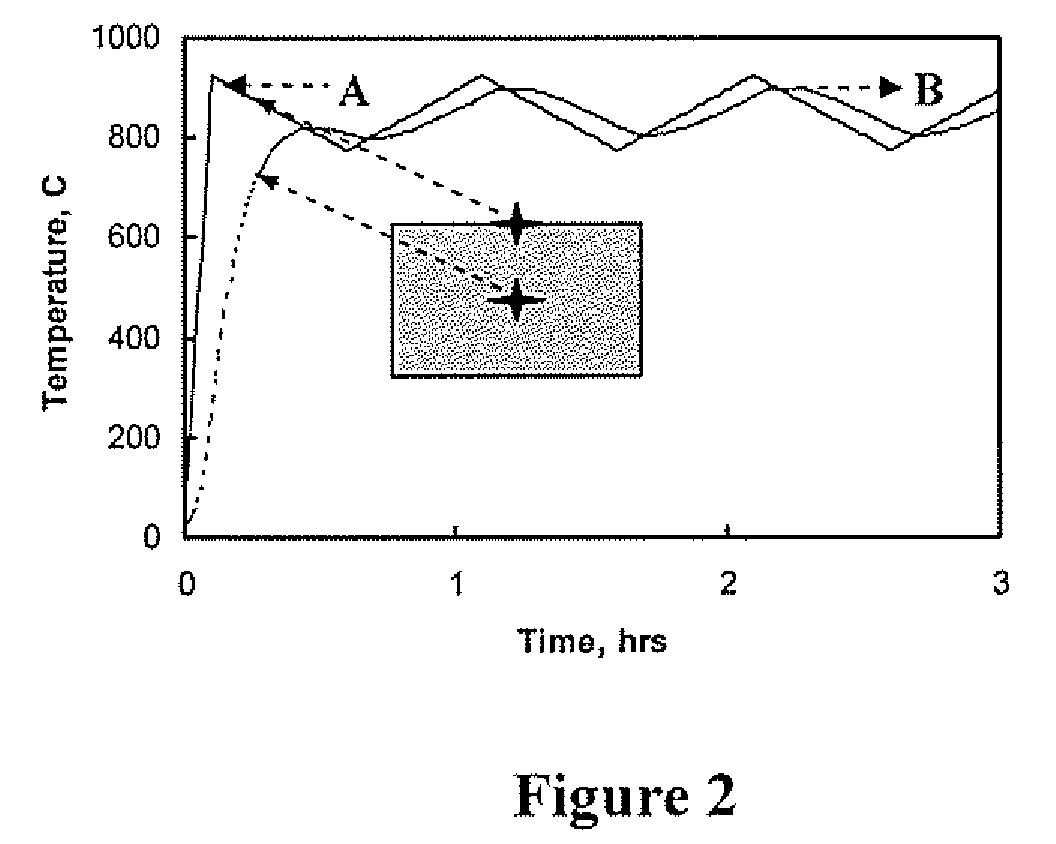

Method of thermal treatment of components

InactiveUS7560669B2Improve performanceShorten treatment timeHigh-frequency/infra-red heating bakingBlast furnace detailsRoom temperatureCooling down

A method of thermal treatment of components. The optimum thermal amplitude of the components at which the phase transformation kinetics of the components is maximum is determined by subjecting samples of the components to cyclic thermal processing at various thermal amplitudes by maintaining the upper temperature constant and varying the lower temperature. A thermal amplitude which is higher than the optimum thermal amplitude is selected. The components are subjected to cyclic thermal processing at the thermal amplitude selected above to achieve near uniform phase transformation kinetics of the components across their crosssection. The components are cooled down to room temperature to obtain components with near uniform microstructure and properties.

Owner:TATA CONSULTANCY SERVICES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com