High-speed electroplating method

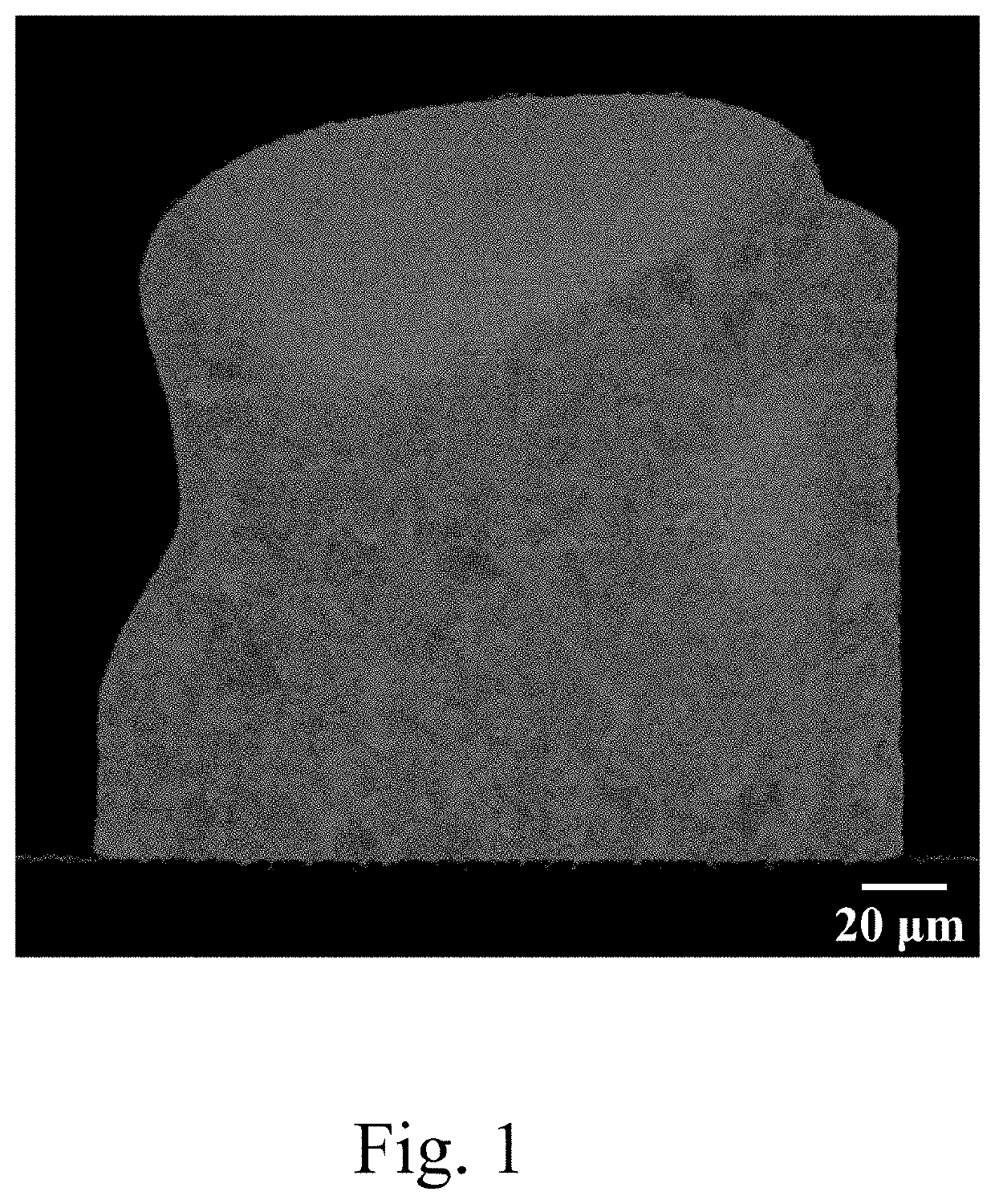

a high-speed electroplating and electrodeposition technology, applied in the field of electroplating methods, can solve the problems of non-uniform electrodeposition and microstructure, such as grain size, non-uniform grain size,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

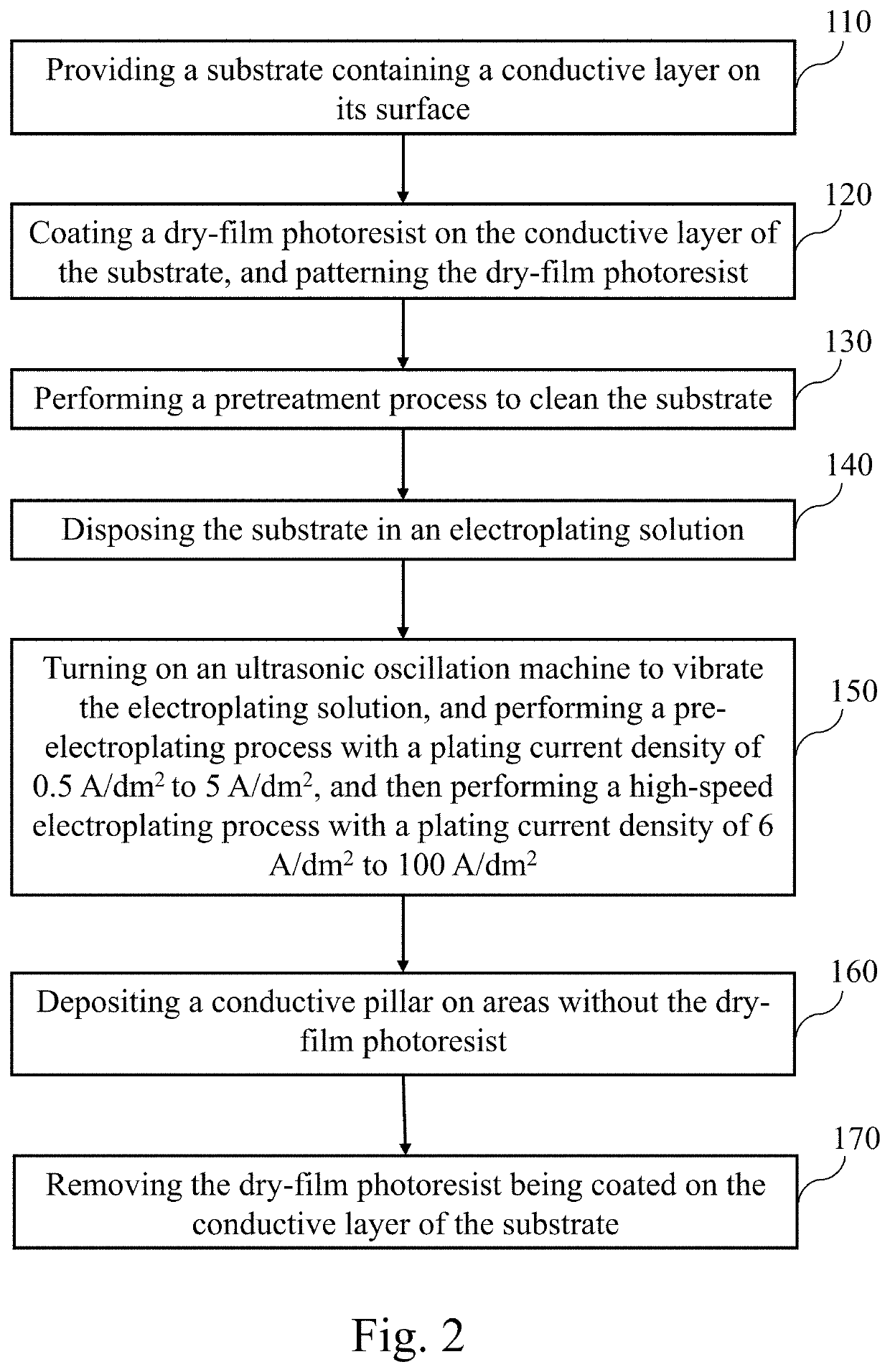

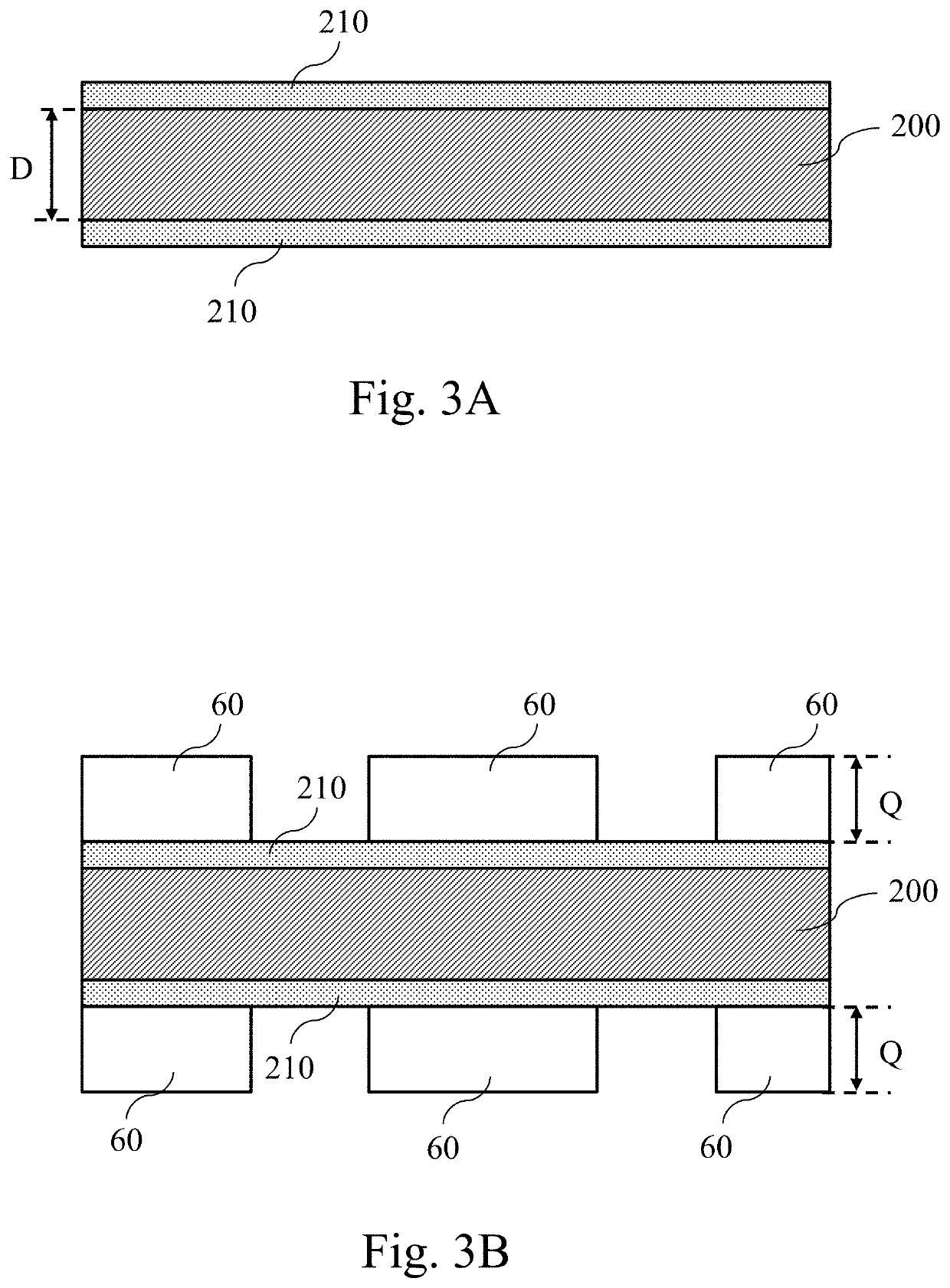

[0040]Please refer to FIG. 2 and FIGS. 3A to 3E, wherein FIG. 2 is a flowchart showing steps for operating a high-speed electroplating method according to the present invention, and FIGS. 3A to 3E are schematic drawings of an embodiment of steps 110, 120, 140 and 150, 160, and 170 of the high-speed electroplating method of FIG. 2. In this embodiment, the high-speed electroplating method includes the following steps: providing a substrate containing a conductive layer on its surface (step 110); coating a dry-film photoresist on the conductive layer of the substrate, and patterning the dry-film photoresist (step 120); performing a pretreatment process to clean the substrate (step 130); disposing the substrate in an electroplating solution (step 140); turning on an ultrasonic oscillation machine to vibrate the electroplating solution, and performing a pre-electroplating process with a plating current density of 0.5 A / dm2 to 5 A / dm2, and then performing a high-speed electroplating proce...

second embodiment

[0051]Please refer to FIG. 5, which is a flowchart showing steps for operating a high-speed electroplating method according to the present invention, the high-speed electroplating method includes the following steps: providing a substrate containing a conductive layer on its surface (step 110); coating a dry-film photoresist on the conductive layer of the substrate, and patterning the dry-film photoresist (step 120); performing a pretreatment process to clean the substrate (step 130); disposing the substrate in an electroplating solution (step 140); turning on an ultrasonic oscillation machine to vibrate the electroplating solution, and turning on a jet flow device to agitate the electroplating solution, and performing a pre-electroplating process with a plating current density of 0.5 A / dm2 to 5 A / dm2, and then performing a high-speed electroplating process with a plating current density of 6 A / dm2 to 100 A / dm2 (step 350); depositing a conductive pillar on areas without the dry-film...

third embodiment

[0056]The high-speed electroplating method of the present invention may be used to form the above-mentioned conductive pillars, and further used to fill the blind-hole structure or the through-hole structure. For details, please refer to FIG. 8 to FIG. 10B, wherein FIG. 8 is a flowchart showing steps for operating a high-speed electroplating method according to the present invention, FIG. 9A is a schematic drawing of an embodiment of a blind-hole structure of step 420 of FIG. 8, FIG. 9B is a schematic drawing of an embodiment of a through-hole structure of step 420 of FIG. 8, FIG. 10A is a schematic drawing of an embodiment of a blind-hole filling via the blind-hole structure of step 460 of FIG. 8, and FIG. 10B is a schematic drawing of an embodiment of a through-hole filling via the through-hole structure of step 460 of FIG. 8. In the embodiment, the high-speed electroplating method includes the following steps: providing a substrate (step 410); forming a blind-hole structure or a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com