Prefabricated T beam and construction method

A construction method and longitudinal beam technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to guarantee construction quality, high construction equipment requirements, poor shrinkage and creep internal force, etc., to solve the problem of longitudinal cracks, The effect of reducing construction difficulty and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment (accompanying drawing).

[0036] In the present invention, unless stated otherwise, the used orientation words such as "longitudinal" refer to the length direction of the bridge, and "transverse" refers to the width direction of the bridge.

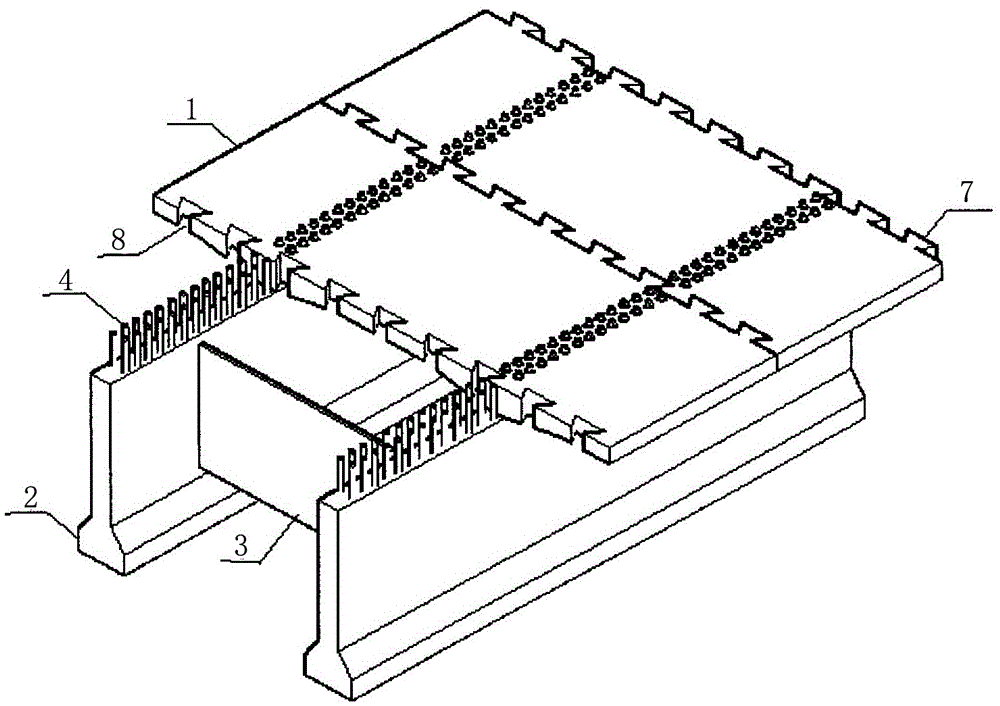

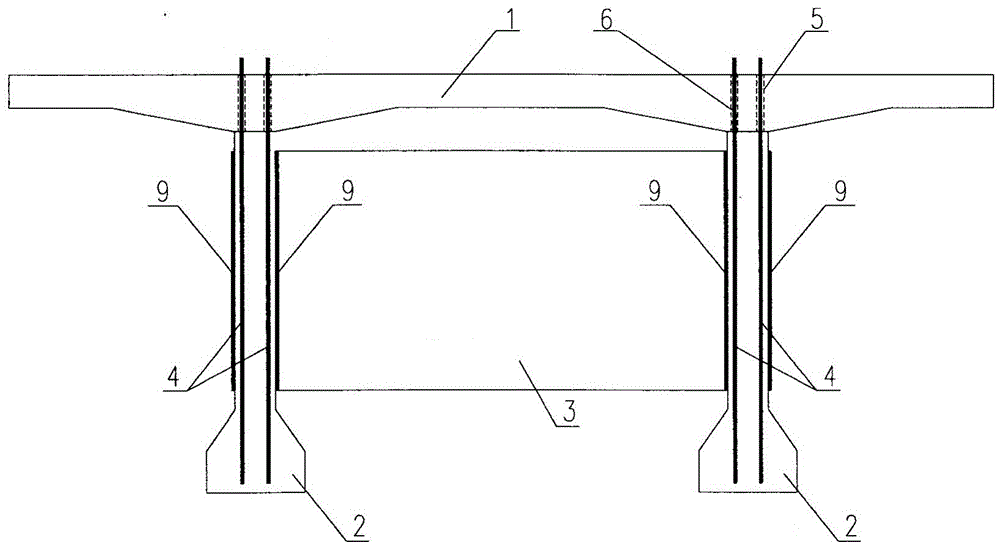

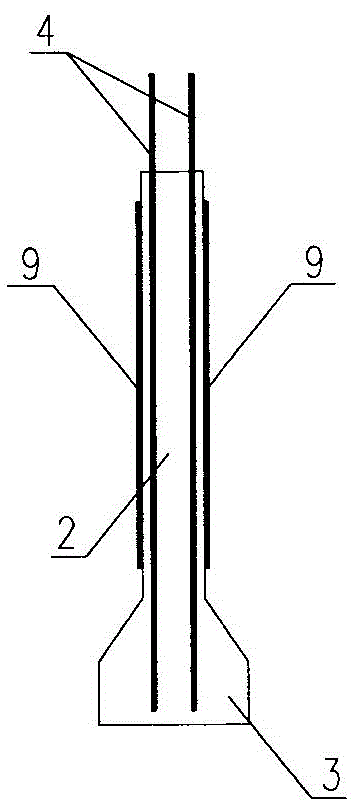

[0037] Such as figure 1 , 2 As shown, the new prefabricated T-beam described in this embodiment includes a bridge deck 1, a longitudinal beam 2, a shear connector and a steel diaphragm 3, and the bridge deck and the longitudinal beam are prefabricated components; the transverse prefabricated width of the bridge deck is The surface width and the longitudinal prefabricated width can be determined according to the transportation conditions. It is recommended to be between 1-2 meters, and the longitudinal prefabricated width is one meter for the convenience of transportation. It can also be increased or decreased according to the transportation condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com