Road bridge variable section hollow high pier slip-form construction method

A construction method and variable cross-section technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as low cost, difficult construction control and safety assurance, and achieve the effect of saving materials, fast construction progress, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

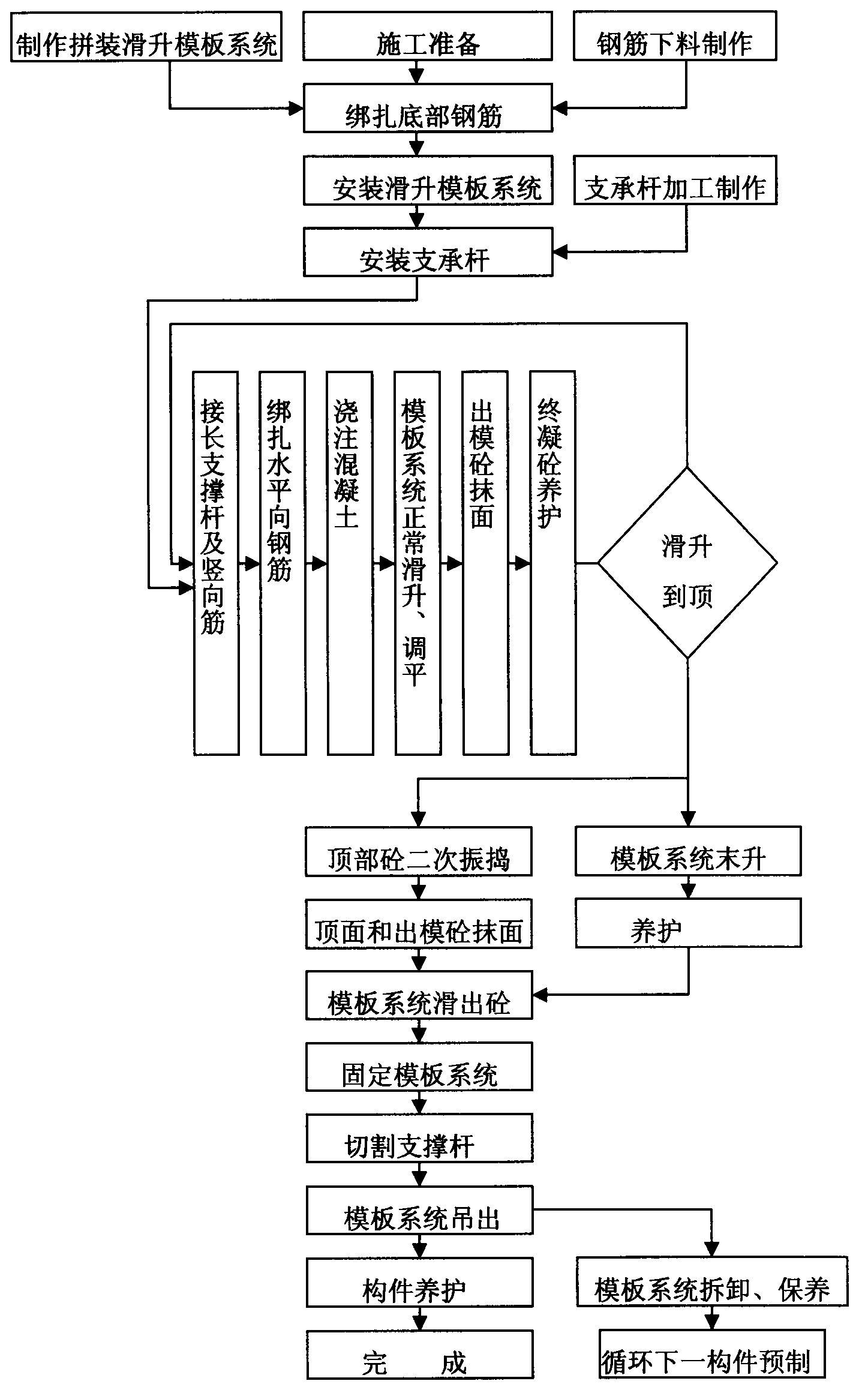

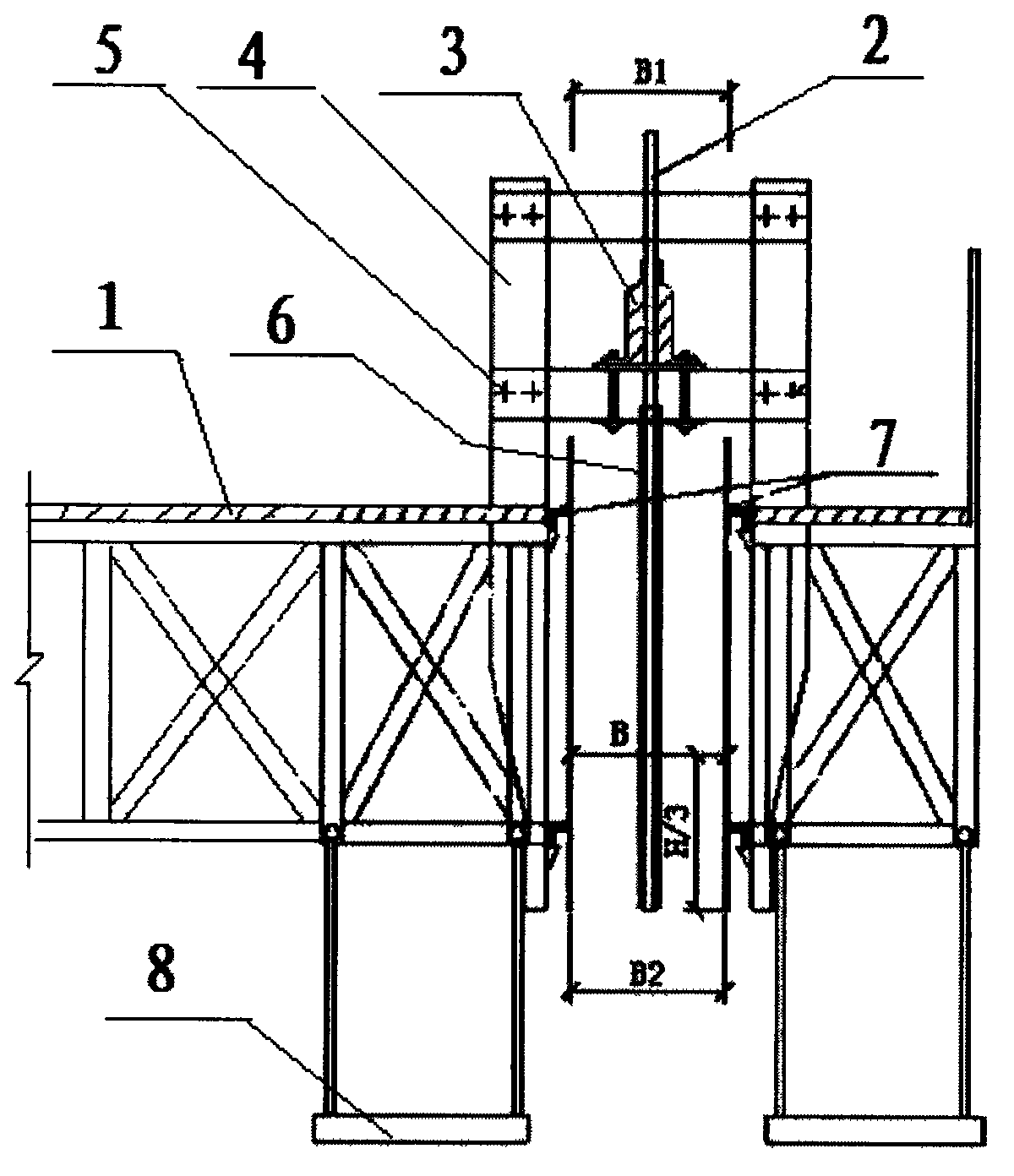

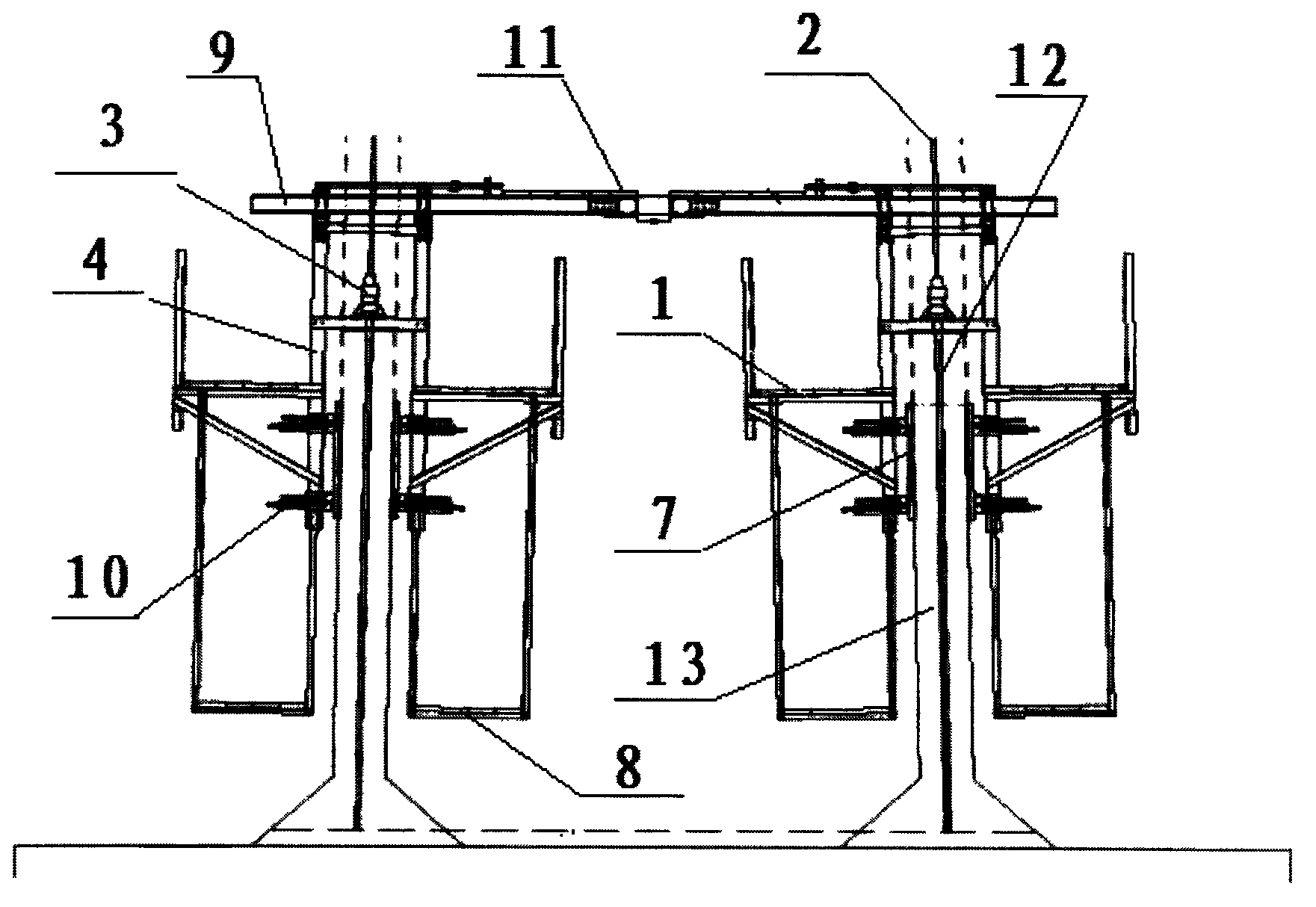

[0022] In the present invention, as attached figure 1 As shown, the specific practical method is as follows: the construction preparation is carried out at the same time to make steel bar blanking and fabricate the assembled sliding formwork system, then bind the bottom steel bars, install the sliding formwork system, and then install the support rod after the processing and manufacture of the support rod 2 2. Then, connect the support rod 2 and the vertical reinforcement, bind the horizontal reinforcement, pour concrete, the formwork system is normally lifted and leveled, the molded concrete is plastered, and the final concrete is cured. Then, slide to the top, and then enter again After connecting the long support rod 2 and the vertical ribs, or, the top concrete is vibrated twice, the top surface and the molded concrete are plastered, and the formwork system slides out of the concrete. In addition, or, directly enter the formwork system after sliding to the top and slide out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com