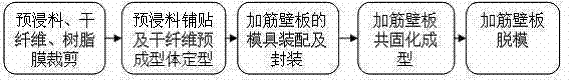

Prepreg/resin film infiltration co-curing forming method for composite stiffened wallboards

A technology of reinforced wall panels and composite materials, applied in the field of composite materials, can solve the problems of long operation time of prepreg blanks, reduce the forming efficiency of parts, increase manufacturing costs, etc., achieve high application value, low manufacturing cost, shorten The effect of manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

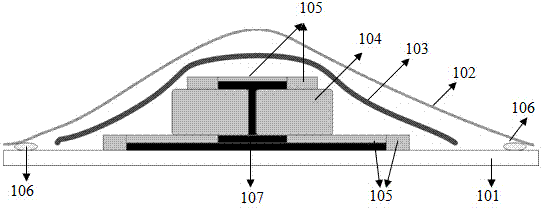

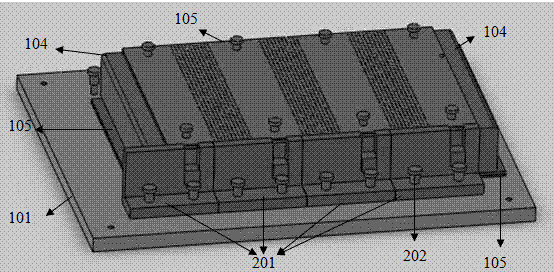

Embodiment 1

[0028] The prepreg / resin film infiltration co-curing process was used to prepare I-shaped reinforced wall panels. Dry fibers are used to prepare the I-shaped rib preform, which is T700 unidirectional carbon fiber cloth, the type of resin film is epoxy resin, and the skin is prepared with T300 carbon fiber / epoxy prepreg. The layering method of skin and ribs is unidirectional layering. During the molding process, the vacuum is greater than 0.095MPa, and the pressure is 0.4MPa, and the temperature is raised to 180°C at 1-2°C / min and kept for 2 hours to complete the curing.

Embodiment 2

[0030] The prepreg / resin film infiltration co-curing process was used to prepare L-shaped reinforced wall panels. Dry fibers are used to prepare L-shaped rib preforms, which are unidirectional glass fiber cloth, the type of resin film is benzoxazine resin, and the skin is made of glass fiber / benzoxazine resin prepreg. The layering method of skin and ribs is ribs: [45 / 0 / -45 / 90 / 45 / 0 / -45 / 0 / 45 / -45], skin: [-45 / 0 / 45 / 90 / -45 / 0 / 0 / 45 / 90 / -45 / 0 / 45]s. During the molding process, the vacuum is greater than 0.098MPa, and the pressure is 0.6MPa, and the temperature is raised to 180°C at 1-2°C / min for 3 hours to complete the curing.

Embodiment 3

[0032] The prepreg / resin film infiltration co-curing process was used to prepare J-shaped reinforced wall panels. The J-shaped rib preform is prepared by dry fiber, which is T800 carbon fiber plain weave cloth, the resin film type is Shuangma resin, and the skin is prepared by T800 carbon fiber / Shuangma resin prepreg. The layering method of skin and ribs is

[0033] Rib: [45 / 0 / -45 / 90 / 0 / 45 / 0 / -45 / 90 / 0 / 45 / 0 / -45 / 0 / 45 / -45]

[0034] Skinning: [-45 / 0 / 45 / 90 / -45 / 0 / 45 / 90 / -45 / 0 / 45 / 90 / -45 / 0 / 45]. During the molding process, the vacuum is greater than 0.095MPa, and the pressure is 0.7MPa, and the temperature is raised to 210°C at 1-2°C / min for 5 hours to complete the curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com