An ultra-thin 3-freedom degree plane motor

A planar motor, degree of freedom technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of high speed, large load, high dynamic characteristics, poor structural integrity, and high center of mass of lithography equipment, and achieve a compact structure. , excellent linearity, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

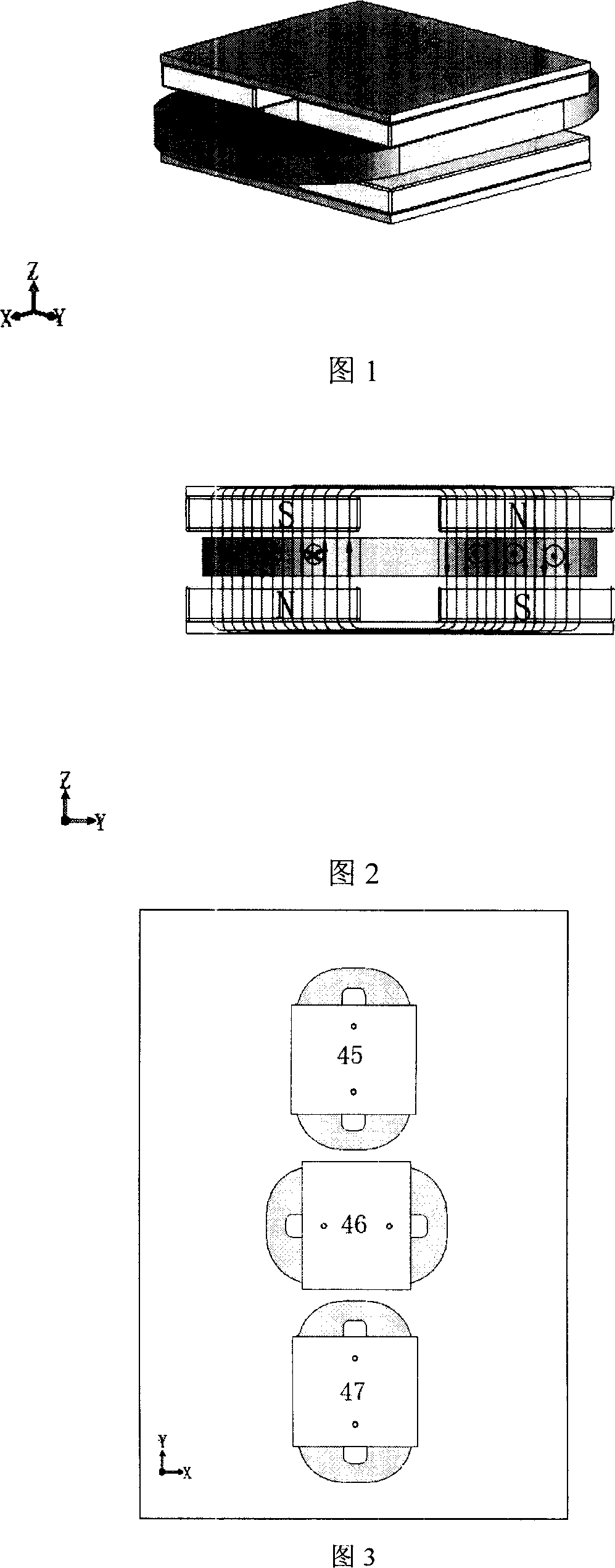

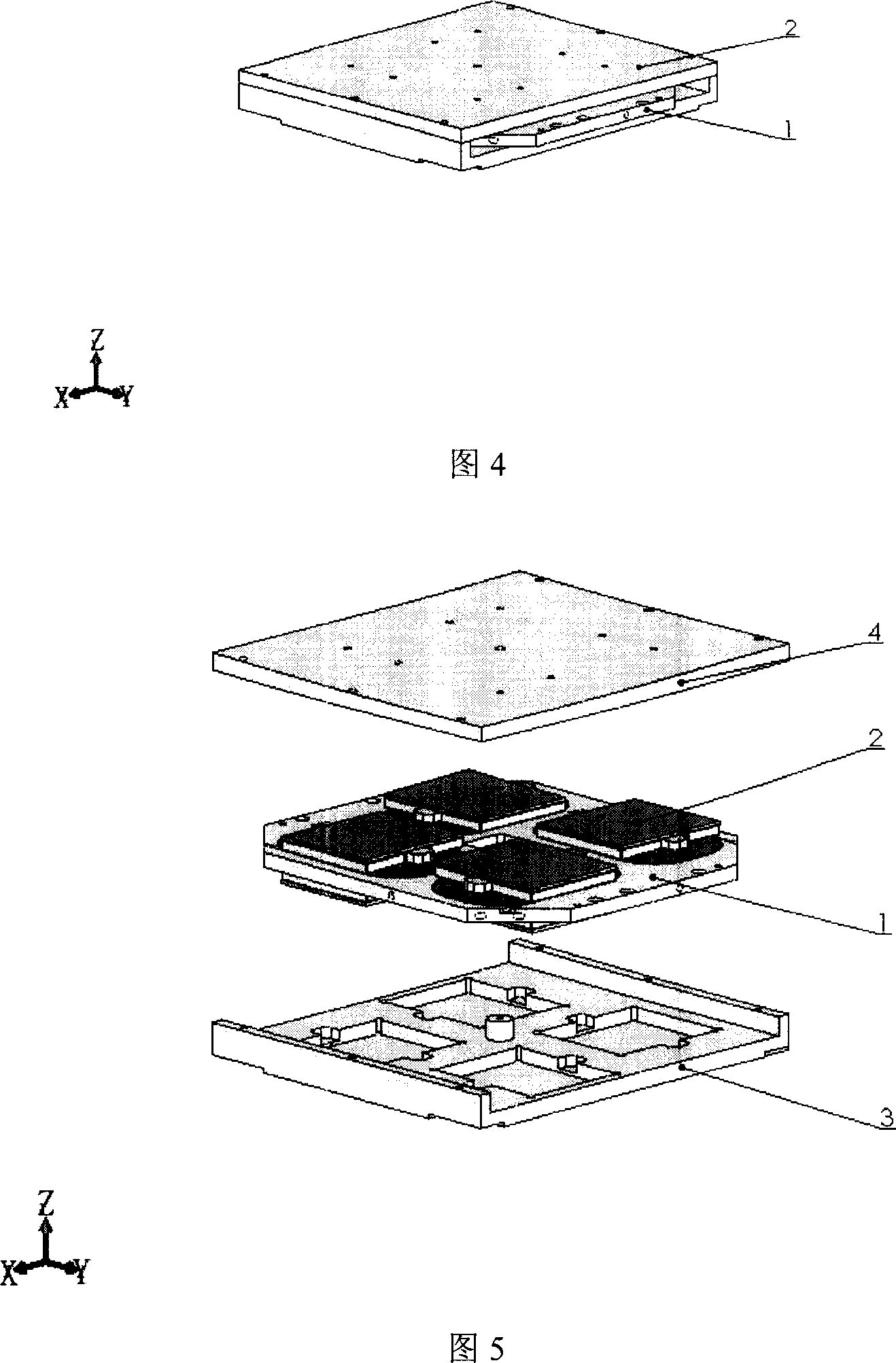

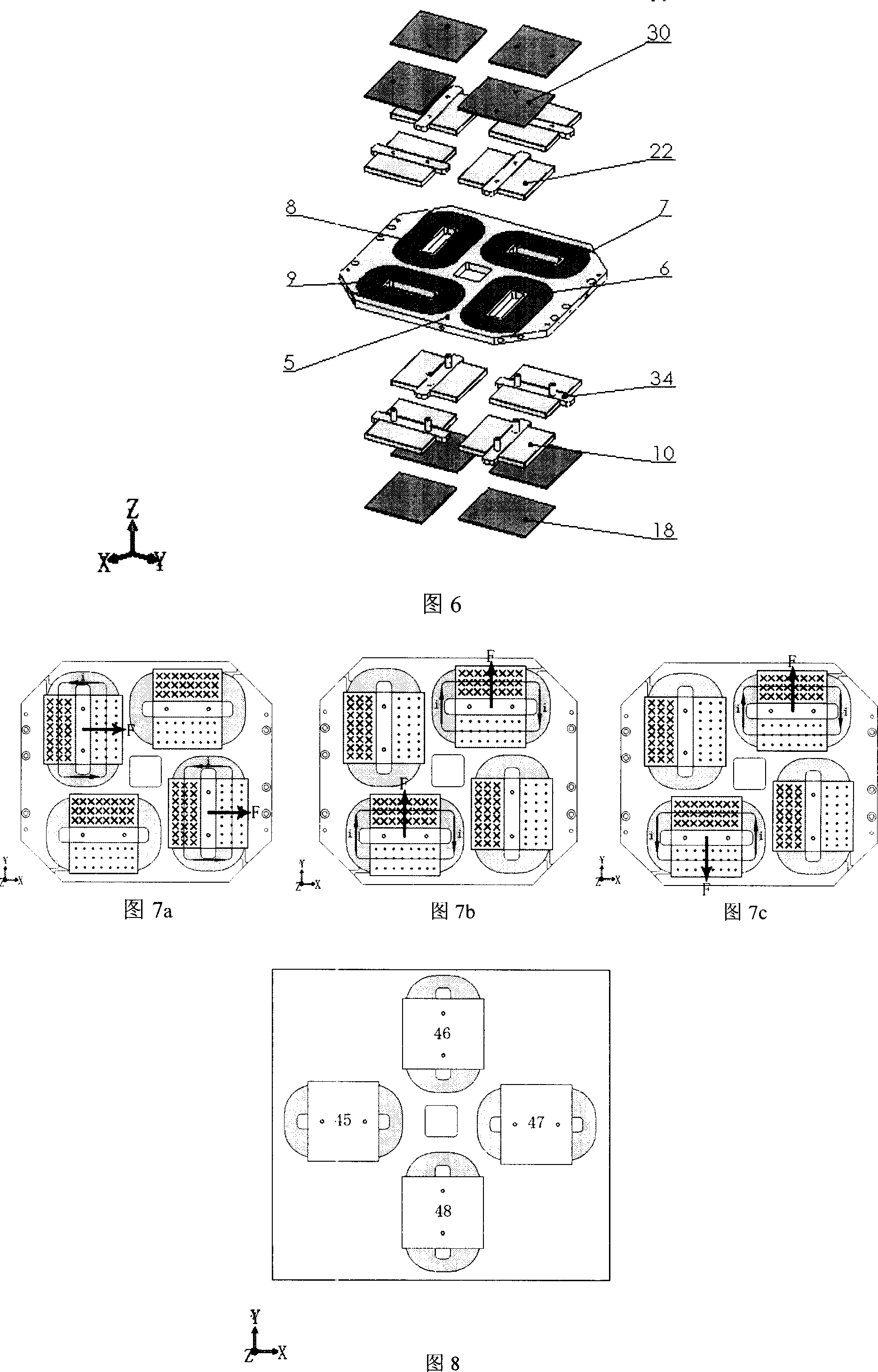

[0029] As shown in FIGS. 1 to 6 , the ultra-thin 3-DOF planar motor of the present invention consists of a coil assembly 1 and a permanent magnet assembly 2 . In the present invention, all the coils are embedded in a single planar frame as the coil assembly 1 . The permanent magnet assembly 2 includes upper and lower planar skeletons, which are connected into one body, and the upper and lower planar skeletons are embedded with permanent magnets and iron yokes in directions corresponding to the coils. The coil assembly 1 is located between the upper and lower plane frames of the permanent magnet assembly 2, and an appropriate gap is ensured. In practical applications, according to the structure of the micro-motion table, the coil assembly can be selected as the stator or as the mover. The planar motor includes three sets of drive units, which realize three degrees of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com