Intelligent-monitored three-dimensional composite material pressure resistant gas cylinder and preparation method thereof

A composite material, intelligent monitoring technology, applied in mechanical equipment, pressure vessels, other household appliances, etc., to achieve the effect of improving integrity, eliminating mechanical weak points between layers, and predicting service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

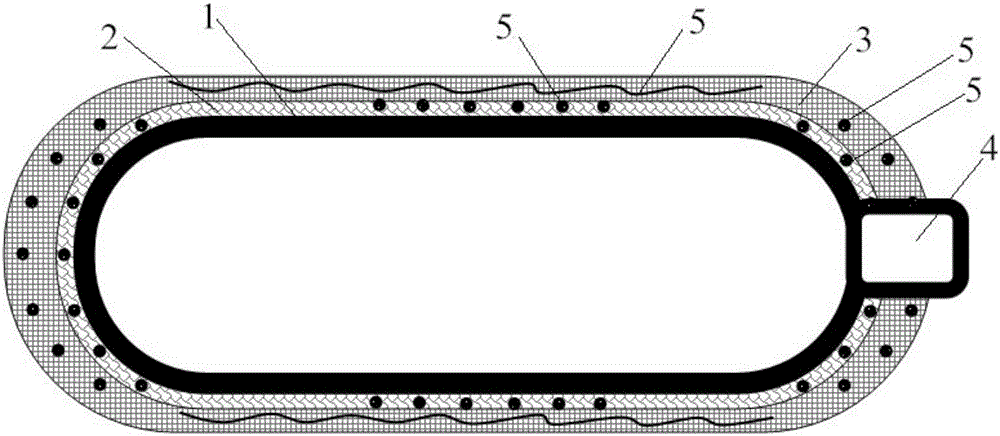

Image

Examples

preparation example Construction

[0036] In the preparation of the metal liner, the metal liner is stamped and formed with a metal material selected from stainless steel, aluminum alloy, and titanium alloy, and then thread-shaped grooves with a depth of 1-3 mm are prepared on the outer surface of the metal liner.

[0037] In the preparation of the plastic interface layer and the pre-embedding of the strain sensing device, the fiber and the resin matrix are mixed and mixed uniformly by mechanical stirring; the plastic interface layer is processed by the injection molding process, and the metal liner layer is fixed in the mold, and at the same time , fix the strain sensing device at a specific position in the mold cavity, inject a uniformly mixed fiber resin melt into the mold cavity by injection molding, cool and mold and demould; wherein, the fiber length is 10-50mm, and the fiber includes the main fiber And auxiliary fiber, main fiber is carbon fiber, auxiliary fiber is a kind of in silicon carbide fiber, alum...

Embodiment 1

[0042] A specific preparation method for an intelligent monitoring three-dimensional composite material pressure-resistant gas cylinder, the steps are as follows:

[0043] (1) Preparation of the metal liner: the metal liner is stamped and formed with stainless steel, and the thickness of the metal liner is 5mm. After the metal liner is formed, a threaded groove with a depth of 1mm is prepared on its outer surface;

[0044] (2) Preparation of the plastic interface layer and pre-embedment of the strain sensing device: use polyurethane resin with a content of 40% as the resin matrix, mix it with the fiber, and mix it evenly by mechanical stirring. The average length of the fiber is 10mm, and the fiber includes The main fiber and auxiliary fiber, the main fiber is carbon fiber, the auxiliary fiber is silicon carbide fiber, the weight ratio of carbon fiber and silicon carbide fiber is 4:1; the plastic interface layer is processed by injection molding technology, and the stainless st...

Embodiment 2

[0048] A specific preparation method for an intelligent monitoring three-dimensional composite material pressure-resistant gas cylinder, the steps are as follows:

[0049] (1) Preparation of the metal liner: the metal liner is stamped and formed with aluminum alloy, and the thickness of the metal liner is 4mm. After the metal liner is formed, a threaded groove with a depth of 1mm is prepared on its outer surface;

[0050] (2) Preparation of the plastic interface layer and embedding of the strain sensing device: 40% polypropylene resin is used as the resin matrix, mixed with the fibers, and mixed evenly by mechanical stirring. The average length of the fibers is 20mm, and the fibers include the main body Fiber and auxiliary fiber, the main fiber is carbon fiber, the auxiliary fiber is alumina fiber, the weight ratio of carbon fiber and alumina fiber is 5:1; the plastic interface layer is processed by injection molding technology, and the aluminum alloy liner is fixed in the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com