Steel wire rope insertion plaited rope sling and manufacturing method thereof

A manufacturing method and technology for wire ropes are applied in the field of wire rope slings, which can solve the problems of inconvenient hoisting operation, low hoisting weight, hidden safety hazards, etc., and achieve the effects of improving structural integrity, improving mechanical performance, and increasing bearing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0028] Below in conjunction with preferred embodiment and accompanying drawing, the present invention will be further described:

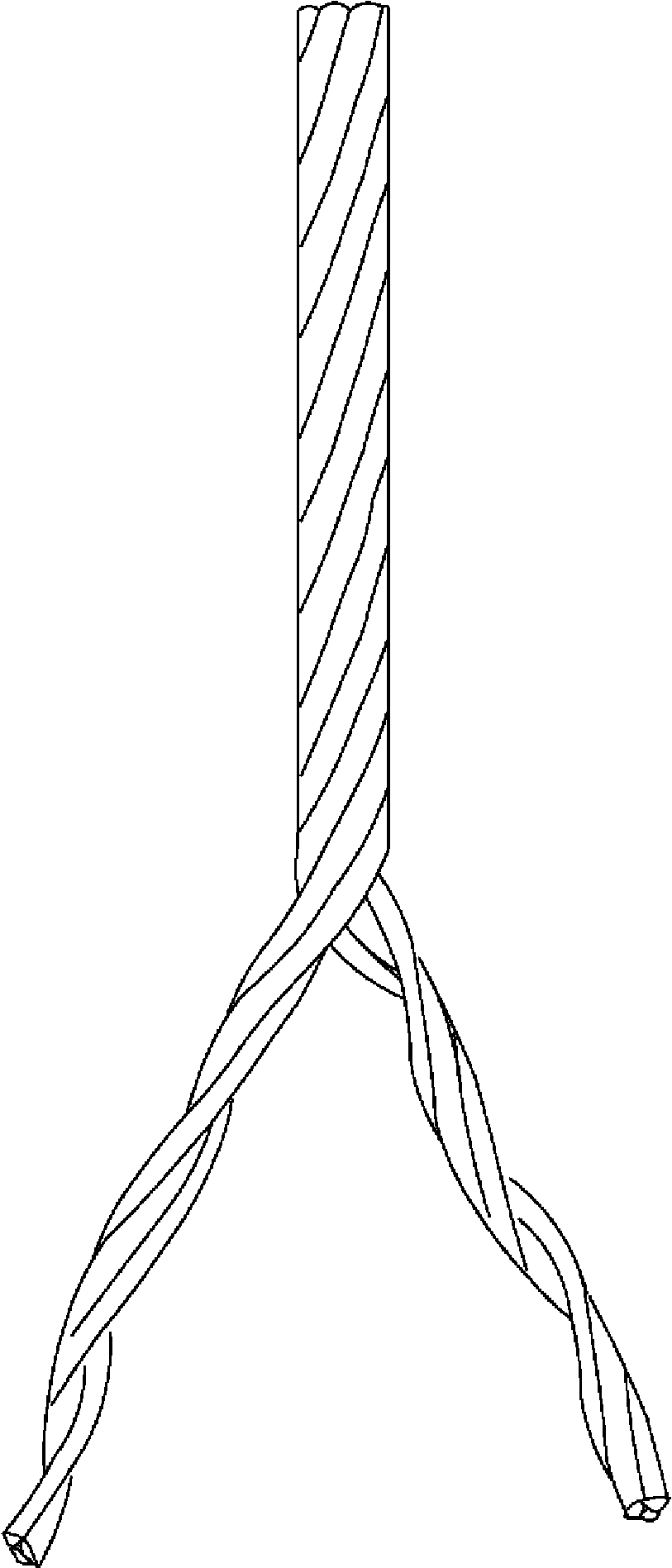

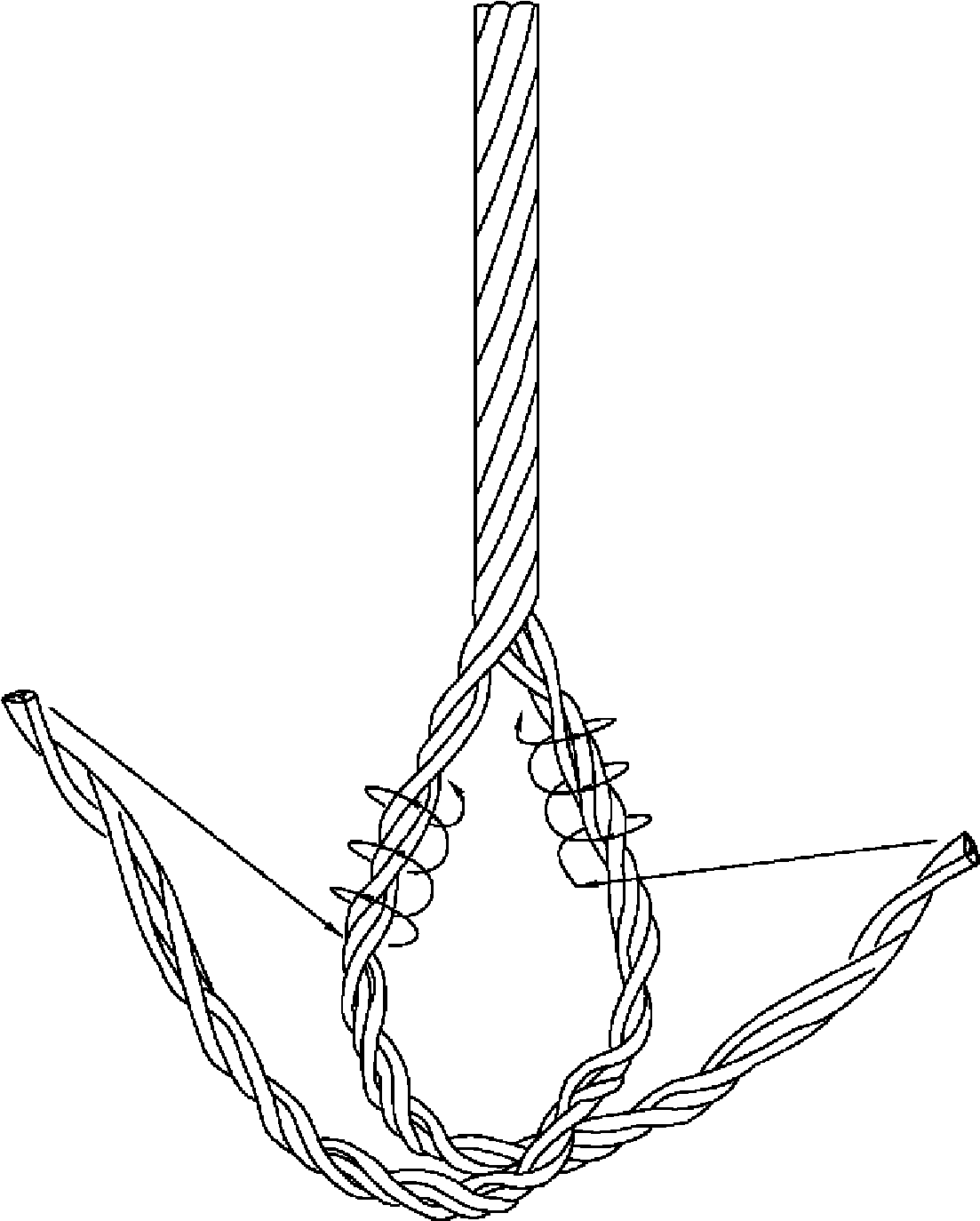

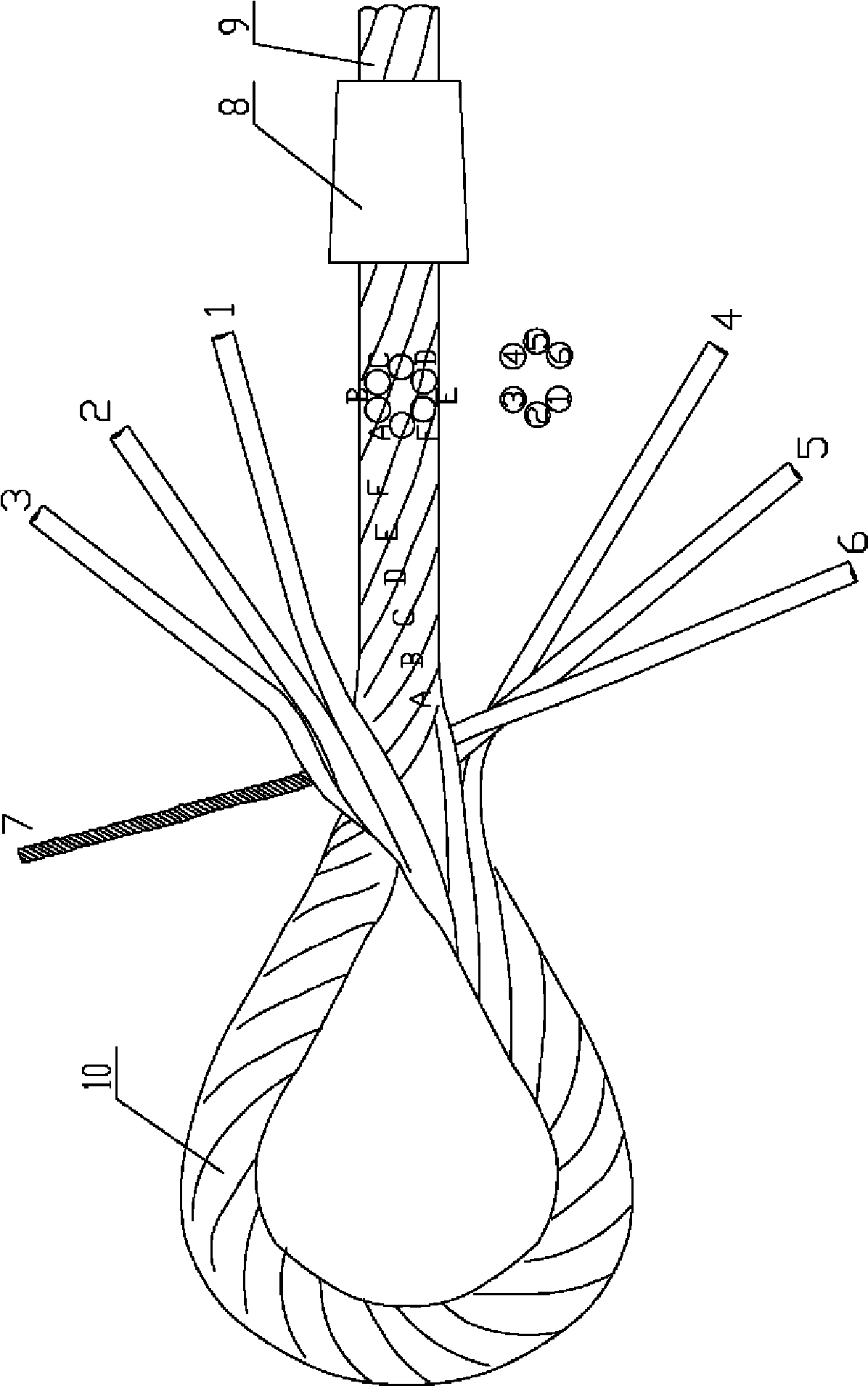

[0029] as attached figure 1 to attach Figure 11 As shown, the steel wire rope insertion rope cover includes alternately twisted six-strand steel wire ropes, which can be obtained by the following steps:

[0030] The first step is to split the end of the alternately twisted six-strand steel wire rope into two pieces, each with three strands and keep the original three strands wound together;

[0031] In the second step, the two separated branches are looped, and the ends on both sides are respectively wound on the other side along the curved shape of the steel wire rope to form the noose 10;

[0032] In the third step, the ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com