Composite foam glass self-heat-preservation veneer-free outer wall board

A composite foam and self-insulation technology, which is applied in insulation, building components, fire prevention, etc., can solve the problems of poor heat resistance and aging resistance of the insulation layer, and easy to burn, so as to reduce construction links, save energy and prevent fire, and meet the requirements of solar energy utilization desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

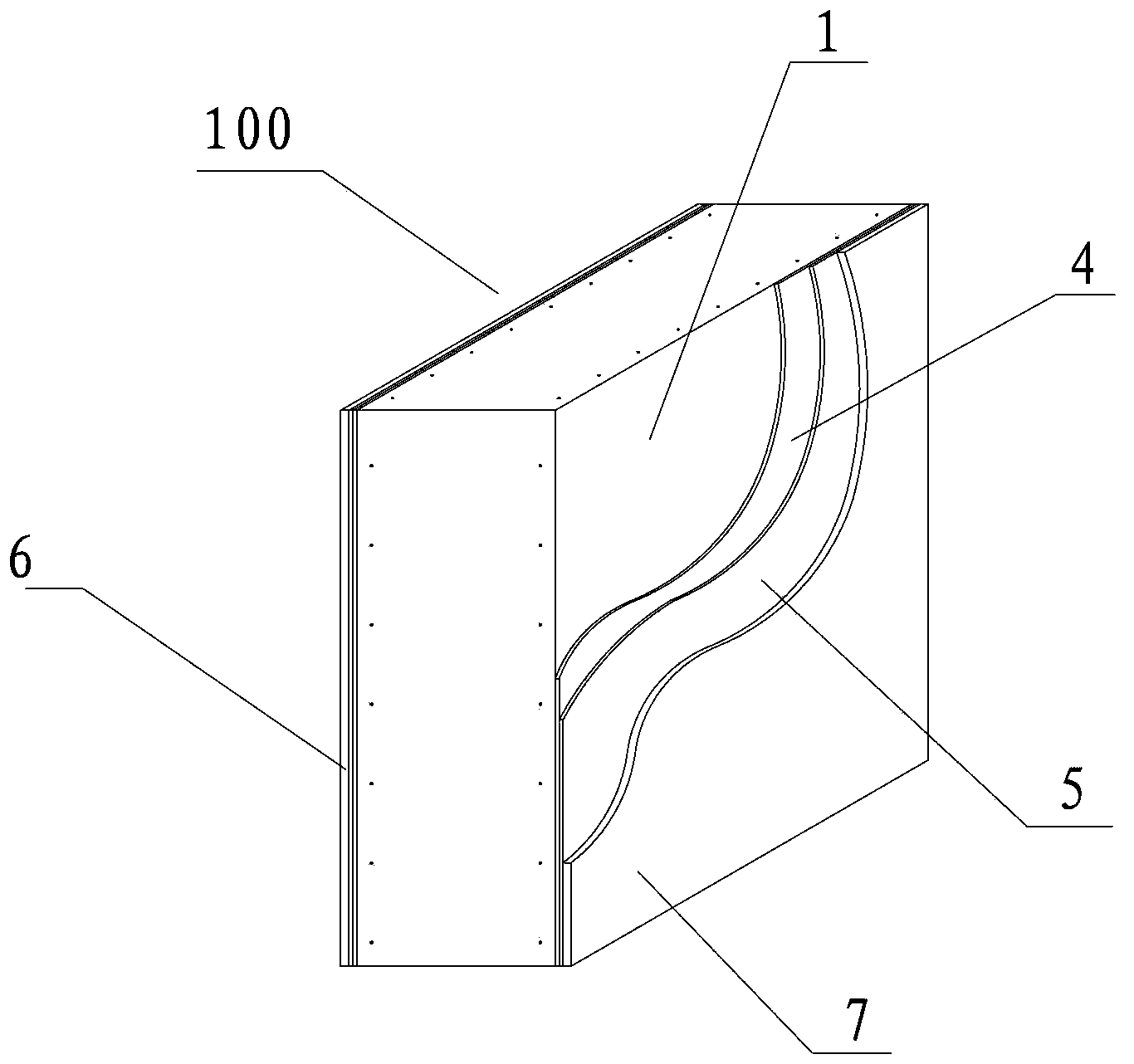

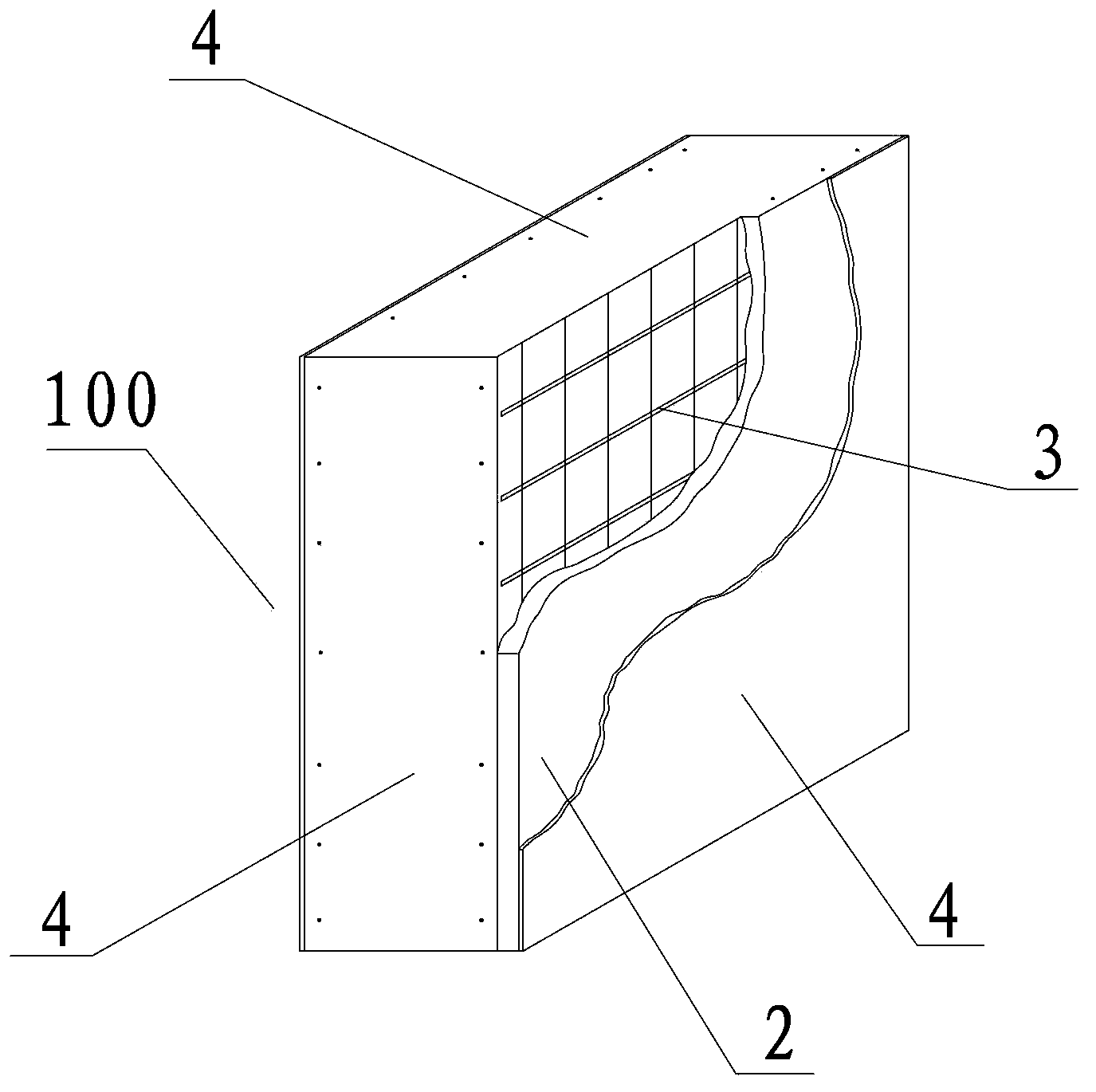

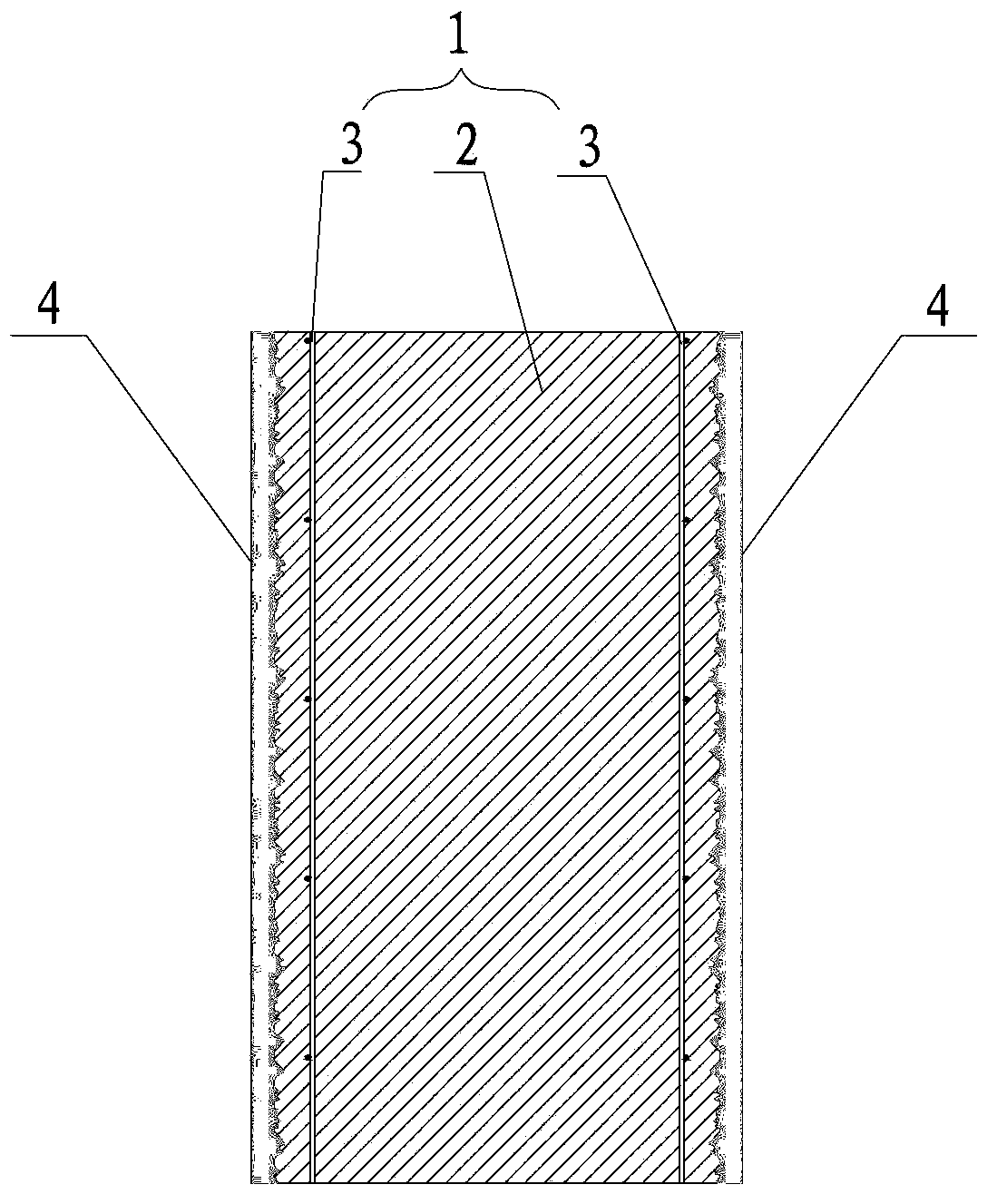

[0028] like Figure 1 to Figure 8 As shown, the composite foam glass self-insulation-free exterior wall panel 100 is composed of a slab 1, a FRP protective layer 4, a carbon fiber reinforcement layer 5, an exterior wall finish layer 6, an interior wall finish layer 7 and is installed on the slab 1. Composed of panel edge components, the FRP protective layer 4 is installed on the outside of the slab 1, and the panel edge components include flat steel bars 11, connecting substrates 10, waterproof rubber strips 12 and stainless steel clips 13. The connection substrate 10 is packaged inside the carbon fiber reinforced layer 5 , and the FRP protective layer 4 has h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com