Connecting piece and construction method for mounting building decorative stone panel

A technology for connecting parts and buildings, which is applied to building components, building structures, buildings, etc., can solve the problems of insufficient tightening of bolts and nuts, difficult to grasp the tightening of nuts, and increase the complexity of installation, so as to achieve a simple construction method. The effect of clear, reduced construction links, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

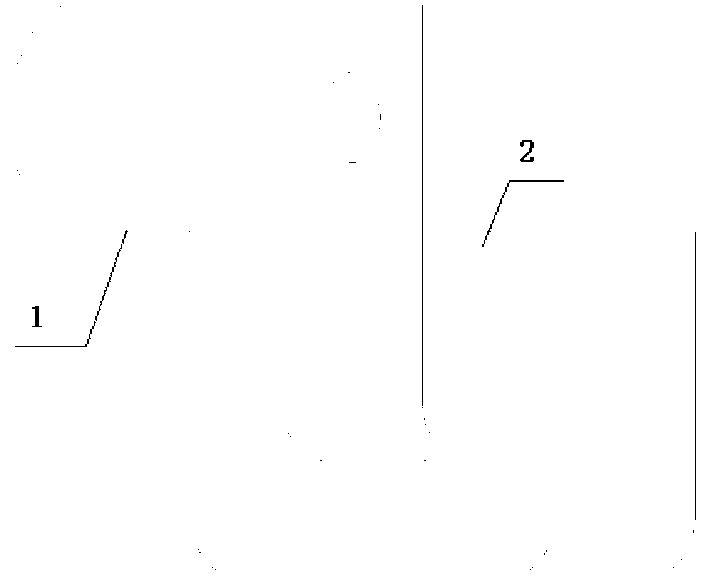

[0038] Such as figure 1 As shown, the present invention is a U-shaped connector for the hanging head 2 . During installation, according to the actual situation, screw the threaded joint 1 into the bolts pre-set on the wall, adjust the distance between the connecting piece and the wall, and realize the positioning of the connecting piece through the positioning pin hole set in the threaded joint 1 to avoid The connecting piece slides circumferentially, and the stone panel which is pre-opened with a vertical notch matched with the hanging joint 2 is hung into the hanging joint 2, usually at the bottom of the stone panel. Before the stone panel is hung into the hanging joint 2, the notch can also be filled with adhesive or structural glue to enhance stability.

Embodiment 2

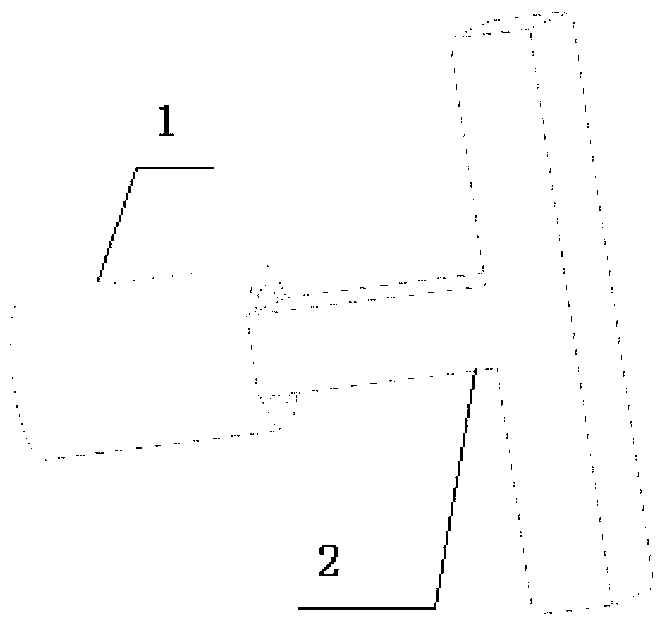

[0040] Such as figure 2 As shown, the present invention is a T-shaped connector for the hanging joint 2 . When installing, as described in Embodiment 1, install the positioning connector first, then hang a stone panel with a matching notch on the bottom into the upper part of the T-shaped hanging joint, and push the other stone panel with a matching notch on the top. The lower part of the T-shaped hook joint. Similarly, before the stone panel is hung into the joint, adhesive or structural glue can be filled into the notch to enhance the stability.

Embodiment 3

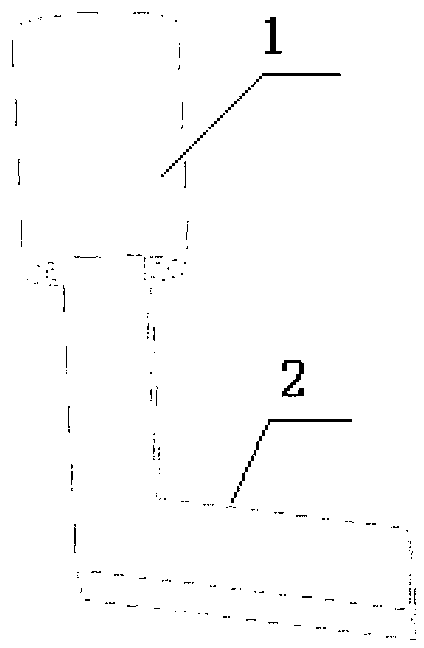

[0042] Such as image 3 As shown, the present invention is a substantially L-shaped connector for the hook joint 2. The hanger joint 2 has a straight plate extending axially along the threaded joint and a slightly upwardly inclined hook plate integrated with the straight plate. The upward-sloping hooking plate can better hook the stone panel, improve the force of the hanging anchor, and make the hanging anchor more stable. Its specific method of installation and use is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com