Method for replacing ground wire by crossing high-speed rail through old wire net sealing

A technology of conducting ground wire and wire, applied in the direction of overhead line/cable equipment, etc., can solve the problems of long construction period and high construction cost, and achieve the effect of reducing construction links, high safety, and easy promotion and implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0059] A method for replacing the ground wire across the high-speed rail by using the old wire to seal the network, the implementation process includes the following steps:

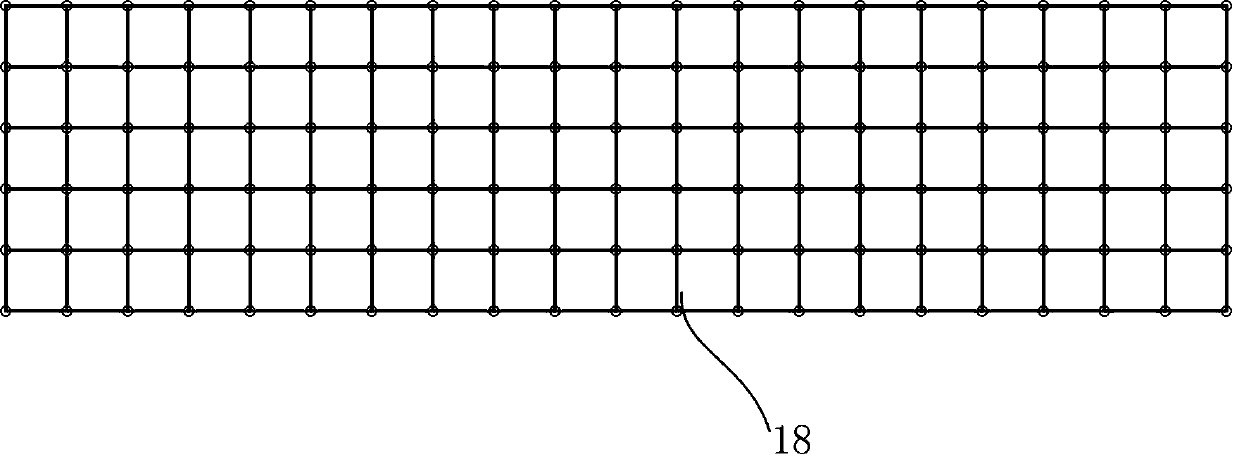

[0060] S1: if figure 1 As shown, weaving capping nets 18 on the ground, each capping net 18 adopts Φ12 nylon ropes in both vertical and horizontal directions, and weaves them into grids at a distance of 2m. The net ropes are knotted and fixed. Determine the length and width of the capping net 18 according to the construction conditions of the crossing point;

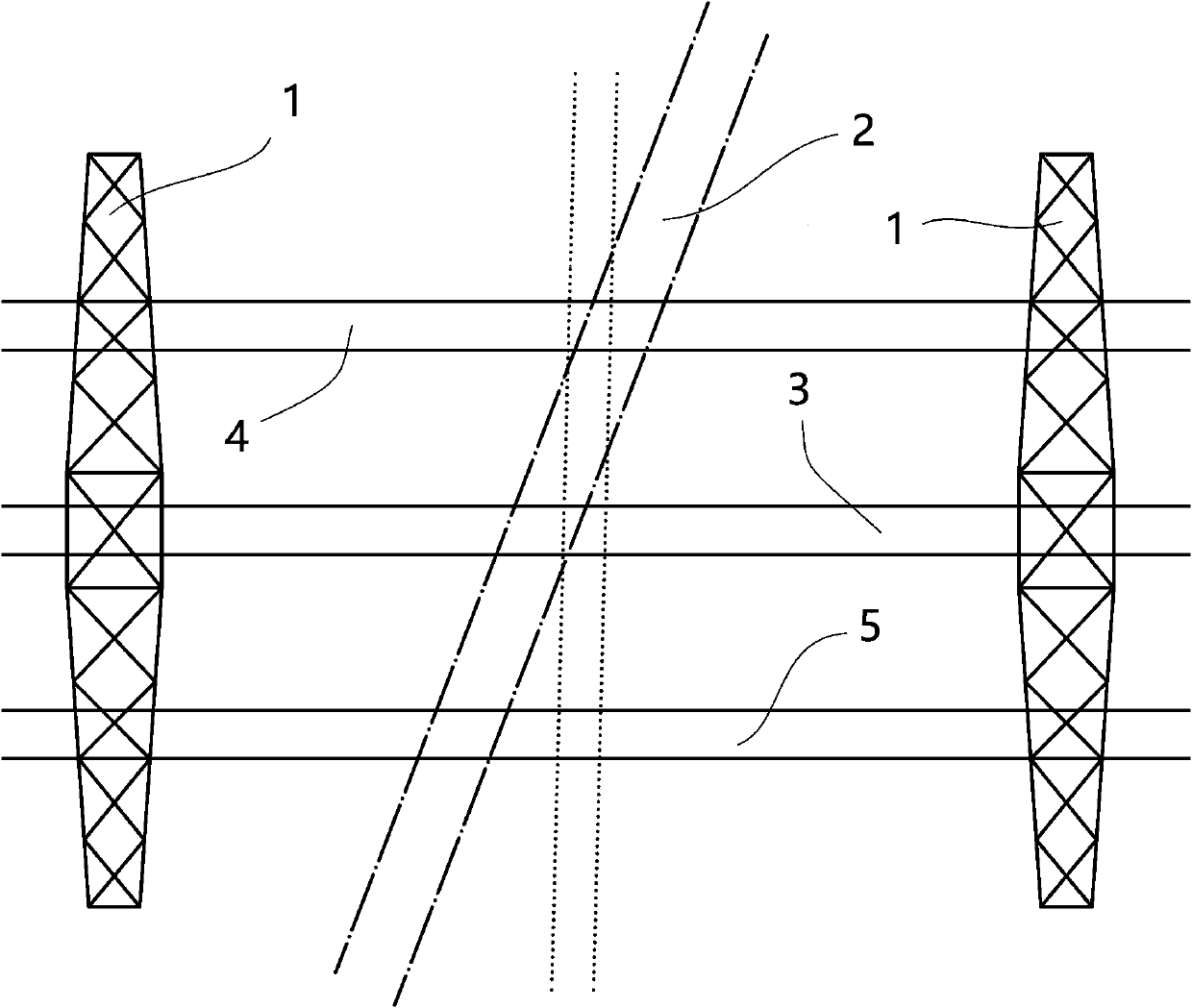

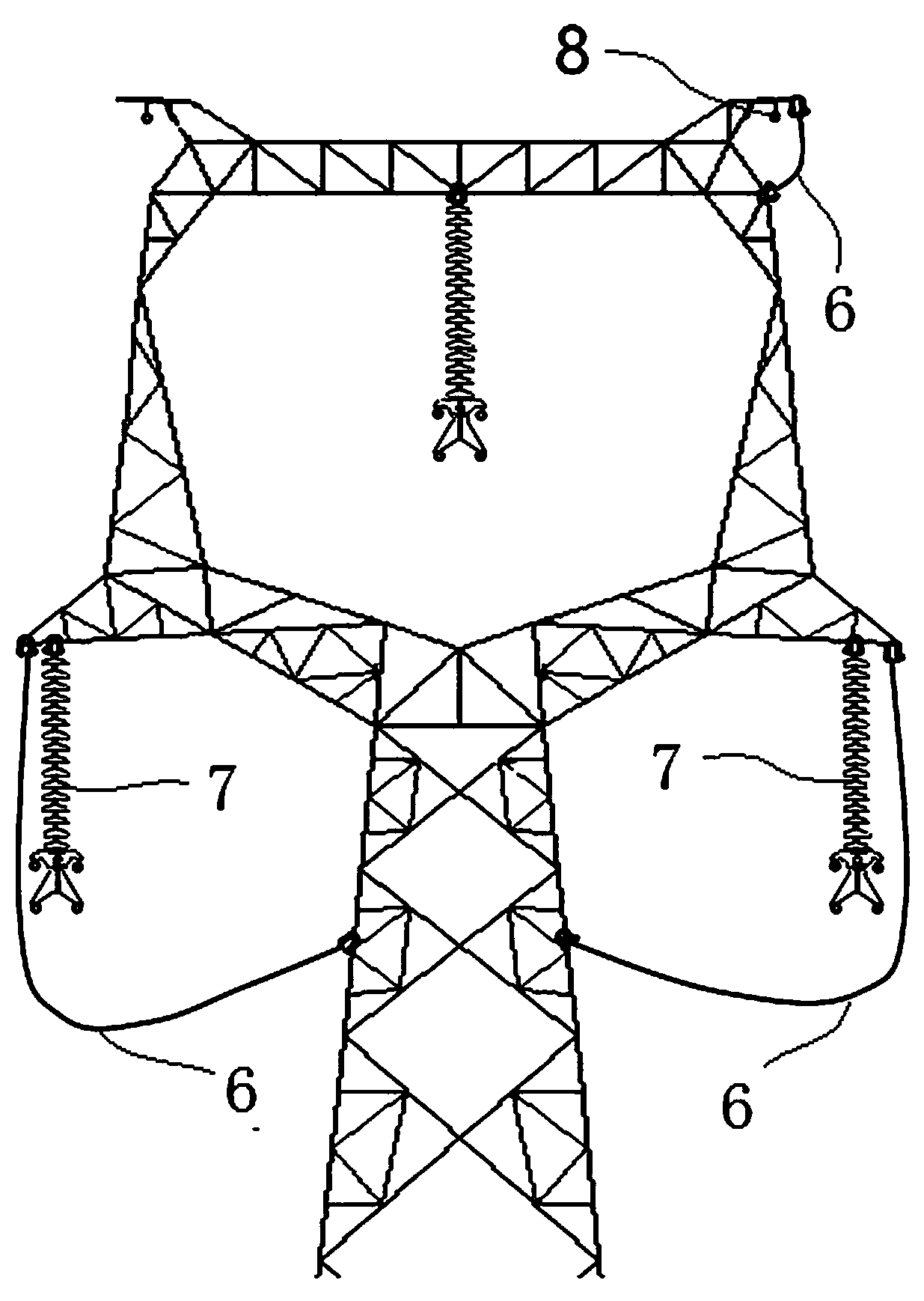

[0061] S2: if figure 2 , 3 As shown, the left-phase conductor 4, the right-phase conductor 5 and the ground wire 8 of the tower 1 on both sides of the high-speed rail 2 are respectively installed with safety wire sleeves 6, the wires adopt Φ17.5×25m safety wire sleeve 6, and the ground wire 8 adopts Φ1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com