A method for replacing ground wires across high-speed railways by using old wires to seal the network

A technology of conducting ground wires and wires, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high construction cost and long construction period, and achieve the effect of reducing construction links, reducing construction costs, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0059] A method for replacing the ground wire across the high-speed rail by using the old wire to seal the network, the implementation process includes the following steps:

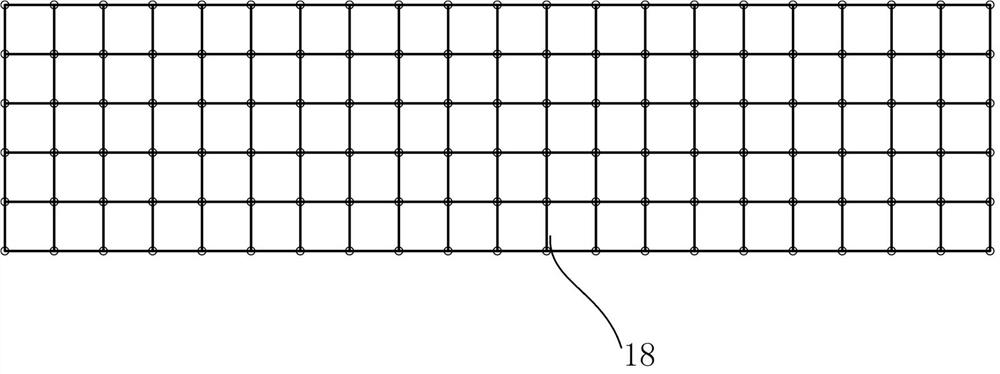

[0060] S1: if figure 1 As shown, weaving capping nets 18 on the ground, each capping net 18 adopts Φ12 nylon ropes in both vertical and horizontal directions, and weaves them into grids at a distance of 2m. The net ropes are knotted and fixed. Determine the length and width of the capping net 18 according to the construction conditions of the crossing point;

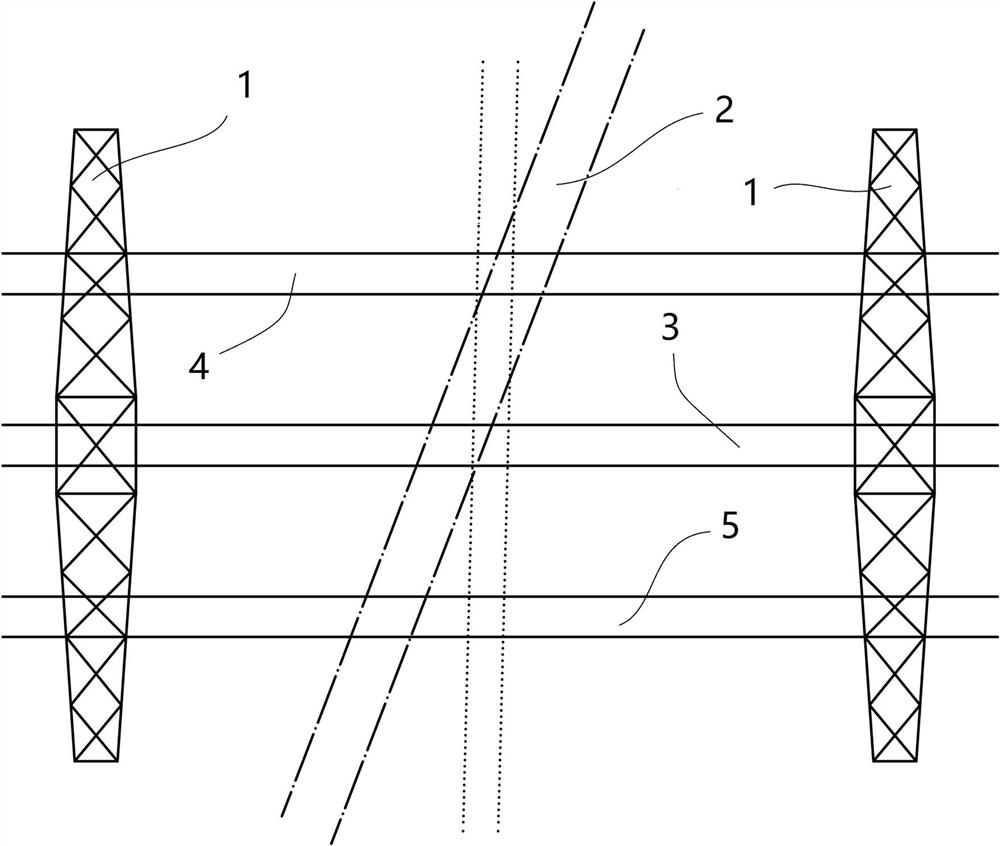

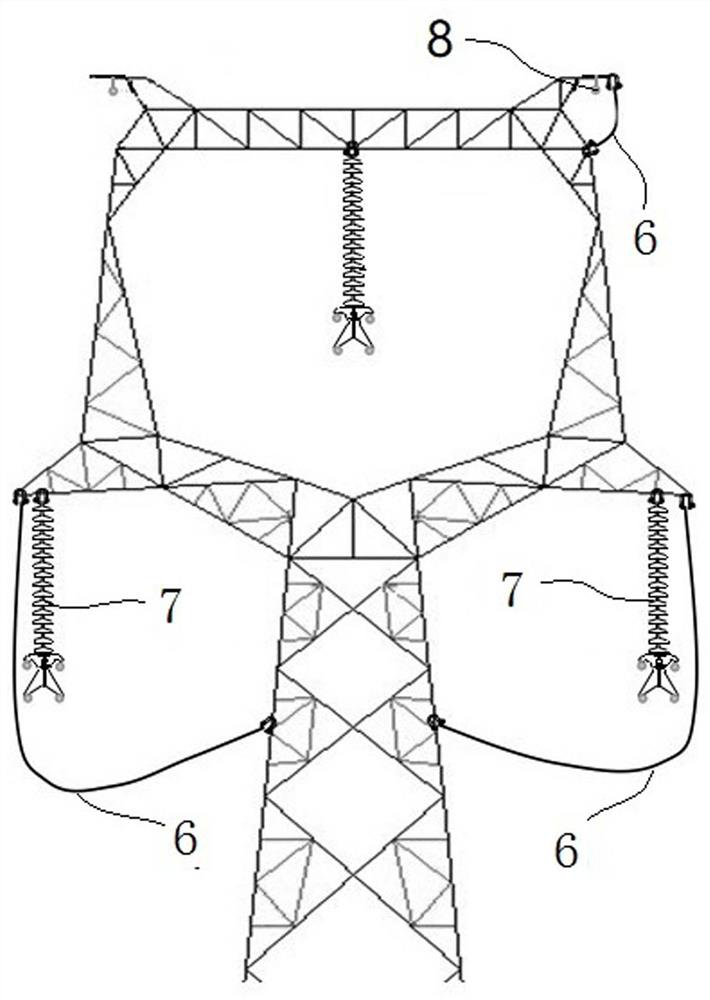

[0061] S2: if figure 2 , 3 As shown, the left-phase conductor 4, the right-phase conductor 5 and the ground wire 8 of the tower 1 on both sides of the high-speed rail 2 are respectively installed with safety wire sleeves 6, the wires adopt Φ17.5×25m safety wire sleeve 6, and the ground wire 8 adopts Φ1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com