Rotary untwisting rack with double cable reels

A technology of untwisting frame and rotating type, which is applied in the field of double cable reel rotating type untwisting equipment, can solve the problems of high cost of transformation, no room for expansion, increase in length and weight of a single submarine cable, and reduce construction links and construction costs. cost and reduce construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

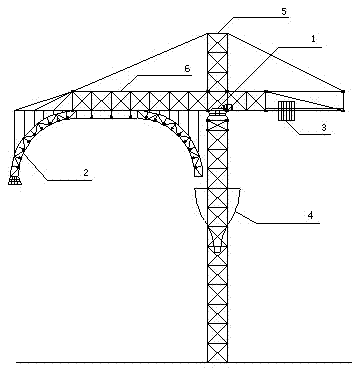

[0011] Such as figure 1 As shown, the double-cable reel rotating type untwisting frame of the present invention includes a slewing mechanism 1, a cable bracket 2, a counterweight device 3, an intermediate cable bracket 4, an untwisting frame column 5, and a rotary type untwisting frame crossbeam 6, Its characteristics are: the top of the back torsion frame column 5 is connected to the rotary back torsion frame beam 6 through the slewing mechanism 1, the rotary back torsion frame beam 6 is provided with a cable bracket 2, and the front end of the rotary back torsion frame beam 6 is equipped with a cable bracket 2 The rotary mechanism 1 rotates along the predetermined trajectory, and is respectively fixed above the two cable storage coils, receives the cables from the two cable reels in turn, and guides the cables into the untwisting frame for continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com