Double-deck concrete faced rock-fill dam and construction method thereof

A face rockfill dam and rockfill technology, which is applied in the field of double-layer face rockfill dam and its construction, can solve the problems that various filling indexes cannot be fully mastered, the construction process of composite material faceplates is complicated, and the construction conditions are required to be high. Suitable for promotion and application, simple construction and few construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

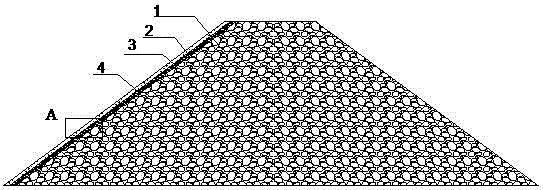

[0023] Such as Figure 1~4 As shown, a double-face rockfill dam includes a rockfill accumulation body 1, a concrete face plate 2, a geomembrane 3 and a polymer composite face plate 4, and the polymer composite face plate 4 is covered on the upstream side of the rockfill accumulation body 1, A geomembrane 3 is covered on the polymer composite panel 4 , and a concrete panel 2 is covered on the geomembrane 3 .

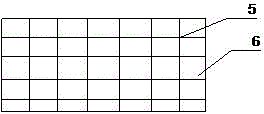

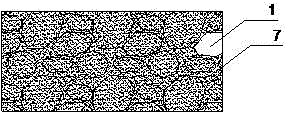

[0024] Among them, the cross-section of the rockfill body 1 is trapezoidal, and the concrete panel 2 is poured from steel bars 5 and self-compacting concrete 6; the reinforcement rate of the concrete panel is 60-100kg / m3. The high polymer composite panel 4 is composed of high polymer 7 and rockfill filled in the pile; the thickness of the high polymer composite panel 4 is not less than 50cm.

[0025] The construction method of a double-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com