Concrete panel void repairing method

A technology of concrete slabs and voids, applied in dams, buildings, barrages, etc., can solve the problems of large investment and low construction efficiency, and achieve the effect of reducing project investment, reducing construction links, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

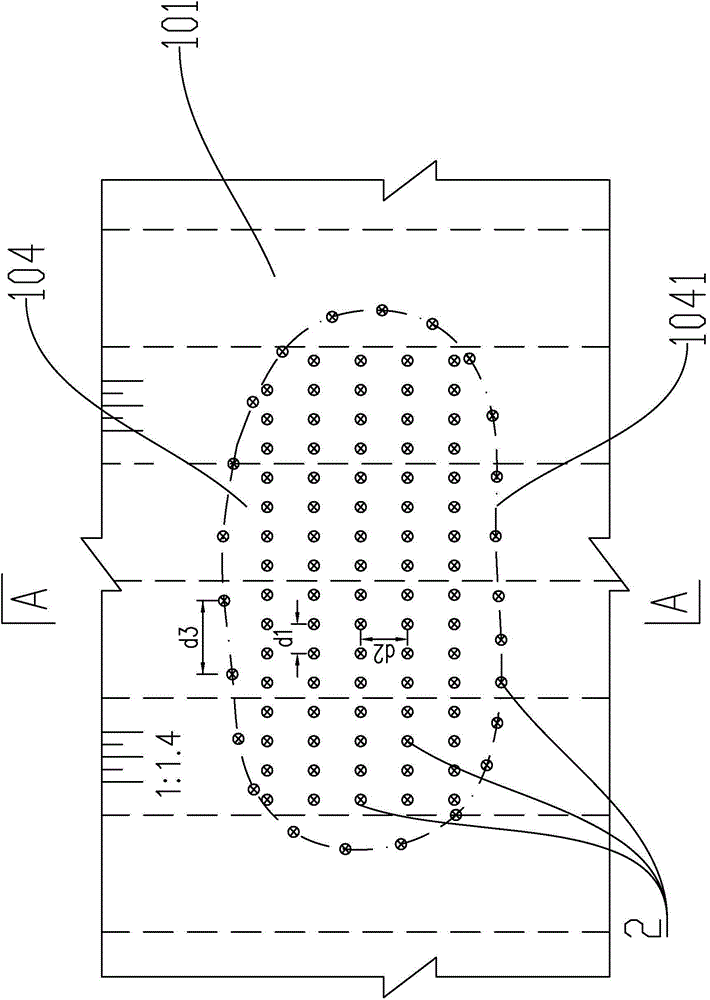

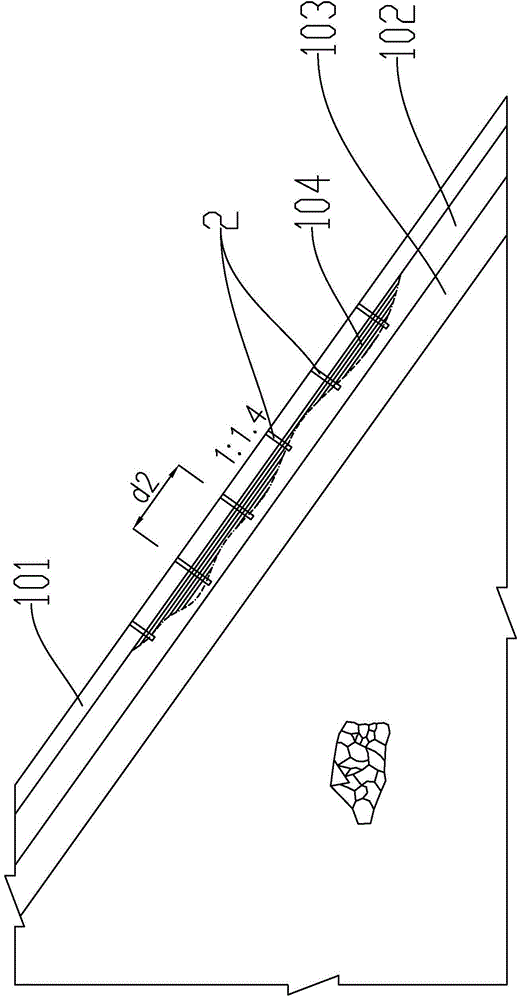

[0019] Such as figure 1 , figure 2 As shown, the dam surface of a concrete face rockfill dam consists of a transition layer 103, a cushion layer 102, and a face plate 101 from bottom to top. This embodiment provides a method for repairing voids in a concrete face face, and the steps are as follows:

[0020] a, void area detection: use LTD ground penetrating radar to detect the panel void area 104 below the panel 101, determine the panel void range, collect information such as the depth of void, and use it for scheme design decision-making; in addition, in The above determined panel void area 104 is subjected to drilling and coring inspection, and the above information is reviewed and corrected to obtain the final panel void area, void depth and other information.

[0021] b. Arrangement of 2 grouting holes: 2 grouting holes are arranged in the hollow area of the panel, and several rows are arranged horizontally. The distance between grouting holes 2 in the same row is d1=2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com