Grouting-to-stop-water construction method of underwater rubble bed

A construction method and technology of riprap foundation bed, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of insignificant economic and social benefits, prolonged construction period, complicated construction process, etc., and achieve obvious economic and social benefits, Speed up construction progress and reduce the effect of construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

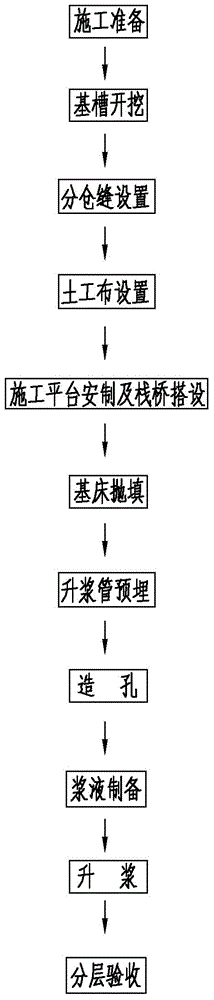

Method used

Image

Examples

Embodiment Construction

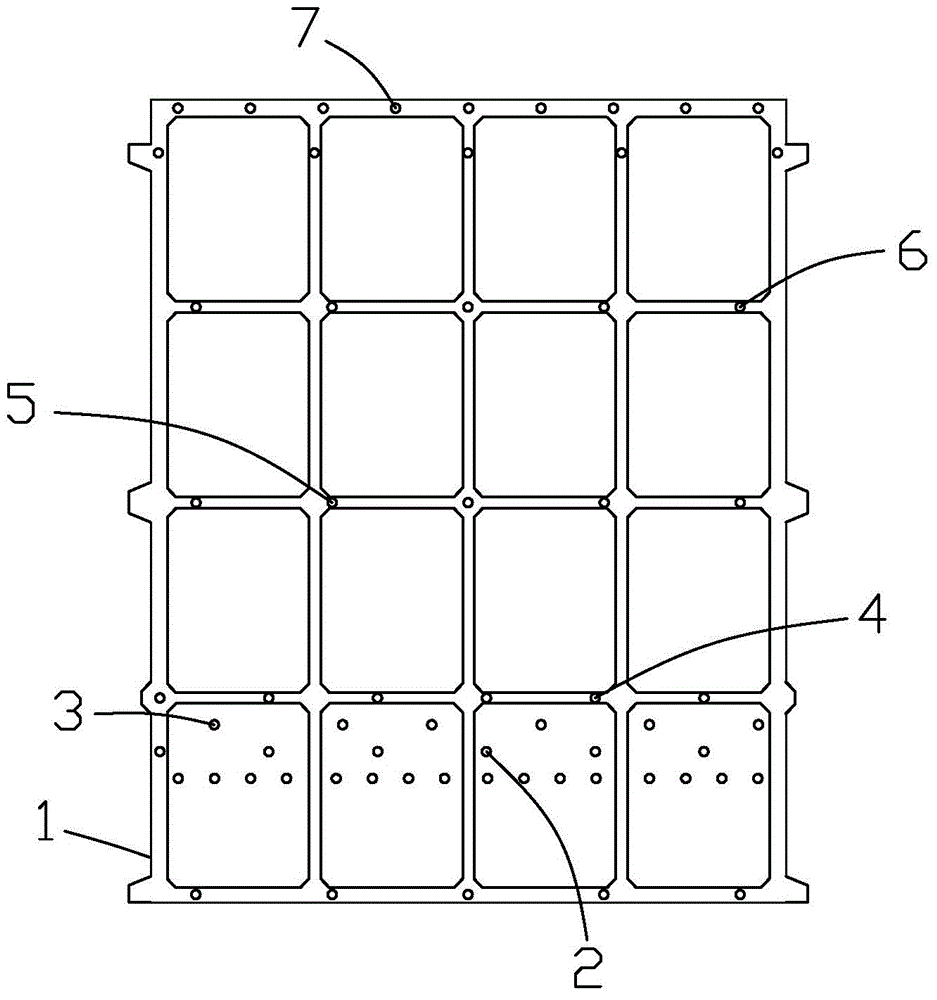

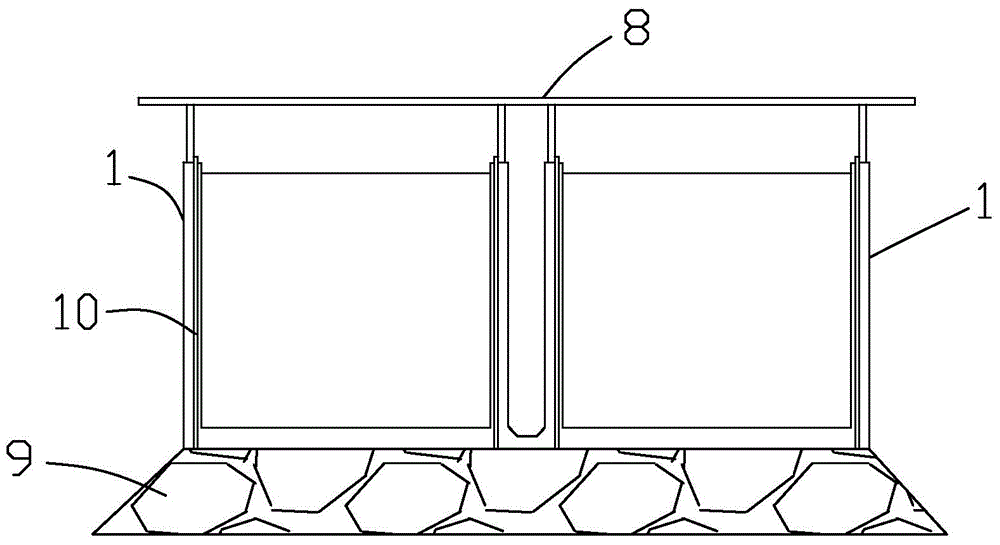

[0036] The present invention adopts the vibrating slurry forming method, the coarse aggregate is directly sunk into the mold by vibrating, and the cement mortar rises relatively to form concrete. , directly affects the smooth progress of subsequent construction projects. The overall strength and function of the raised concrete are gradually formed in water over time, and the entire construction method and operation process are completely in a wet construction state.

[0037] This construction method requires the following materials:

[0038] 1. Cement (the grade is not lower than 32.5, ordinary portland cement), sand (the sand used for pulping is medium-fine sand, the particle size is not more than 2.5mm, and the fineness modulus is 1.6-2.0), water, Additives (water reducer and expansion agent).

[0039] 2. Machinery and equipment: concrete mixing station, mortar pump, slurry storage tank, drilling rig, deep well pump, submersible pump, loader, mixer.

[0040] The inventive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com