System for material control and management in construction process of ultra-high voltage direct current transmission

A UHV DC and management system technology, which is applied in the field of material control and management system in the UHV DC transmission construction process, can solve the problems of required materials, construction personnel and construction links, long scheduling time, inconsistent quality control, etc. problems, to achieve the effect of promoting the use value, reducing construction links, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

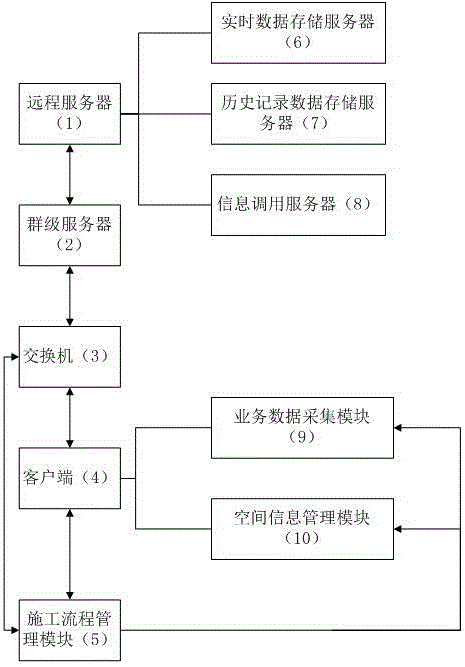

[0023] as attached figure 1 As shown, the material regulation and management system in the UHVDC construction process of the present invention, its structure includes a remote server 1, a group-level server 2, a switch 3, a client 4 and a construction process management module 5, and the construction process management module 5 passes The client 4 is connected to the Internet, and the client 4 and the construction process management module 5 are connected to the group-level server 2 through the switch 3, and the group-level server 2 is connected to the remote server 1 through the Internet; wherein, the remote server 1 is used to store various data and complete various tasks. The calling of class information; remote server 1 comprises real-time data storage server 6, historical record data storage server 7 and information calling server 8, and real-time data storage server 6 is used for storing the various types of data that subordinate server uploads, and historical record data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com