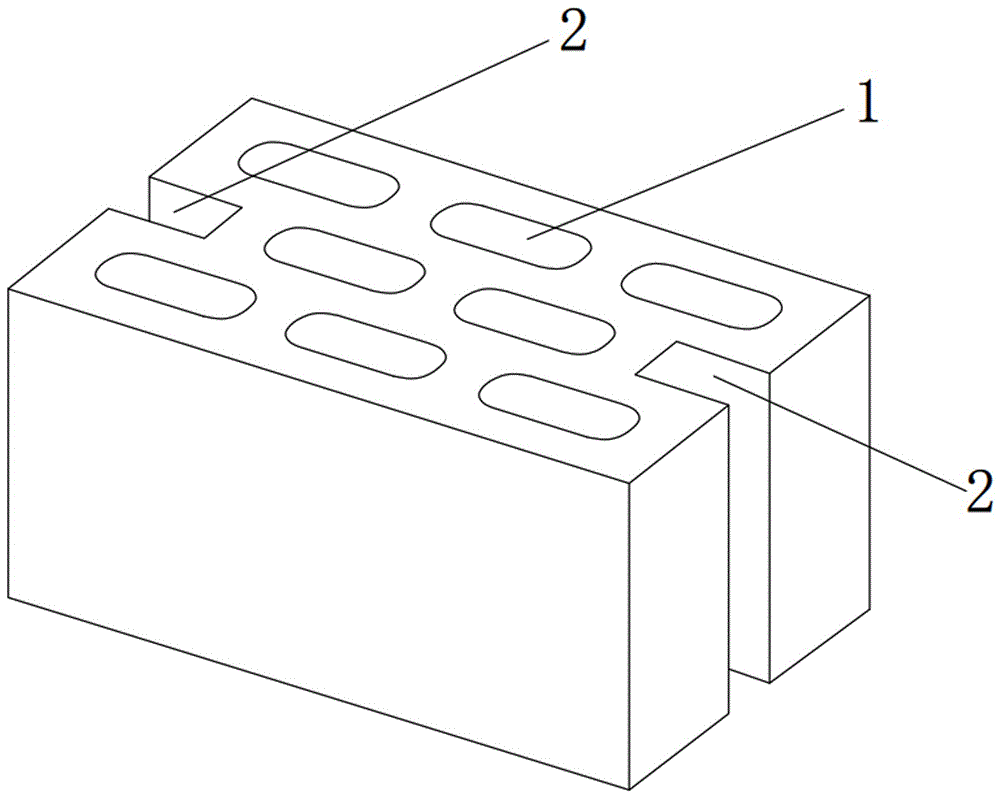

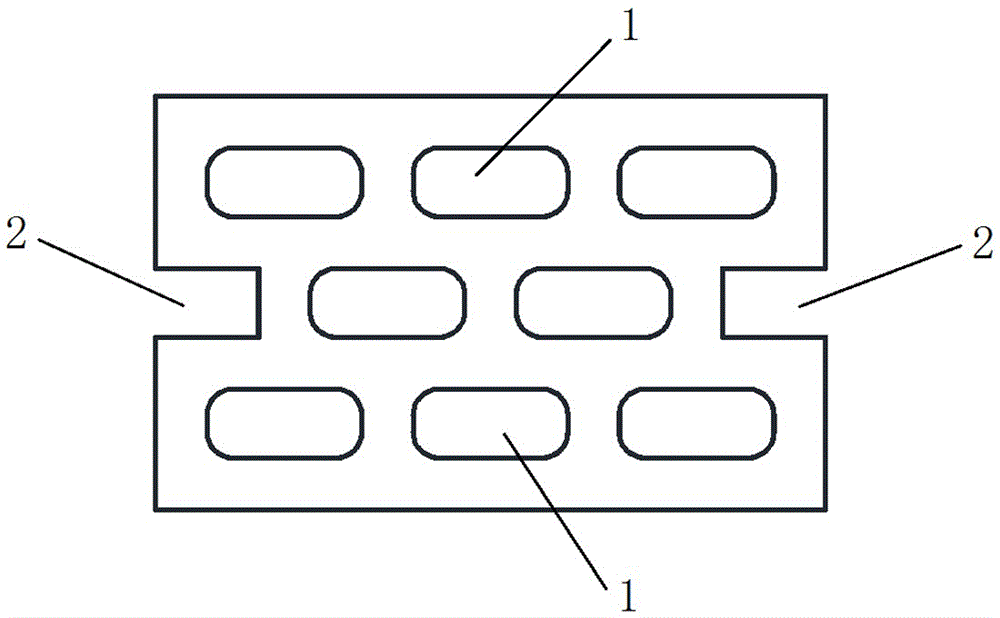

Environment-friendly heat-preserving hollow building block and preparation method thereof

A hollow block and environmental protection technology, applied in the field of building materials and hollow bricklaying, can solve the problems of increasing construction period and cost, harming people's life and property, damage to ground objects, etc., so as to save construction links, enrich output and reduce cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, block raw material is as follows according to quality ratio:

[0036] 1 part of cement;

[0037] 0.35 parts of fly ash;

[0038] 1.465 parts of pumice coarse aggregate;

[0039] Iron tailings sand and pumice sand mixed fine aggregate 1.366 parts;

[0040] Admixture 0.004 parts;

[0041] 0.45 parts of water.

[0042] Iron tailings sand and pumice sand The mass ratio of iron tailings sand and pumice sand in the fine aggregate is 4:6.

[0043] After testing, the dry density of the new environmentally friendly material insulation hollow block produced by this ratio is 890kg / m 3 , the thermal resistance is 1.21m 2 ·K / W, the average compressive strength is 4.7MPa.

Embodiment 2

[0044] Embodiment 2, block raw material is as follows according to quality ratio:

[0045] 1 part of cement;

[0046] 0.4 parts of fly ash;

[0047] 1.515 parts of pumice coarse aggregate;

[0048] Iron tailings sand and pumice sand mixed fine aggregate 1.537 parts;

[0049] Admixture 0.005 parts;

[0050] 0.35 parts of water.

[0051] Iron tailings sand and pumice sand The mass ratio of iron tailings sand and pumice sand in the fine aggregate is 6:4.

[0052] After testing, the dry density of the new environmentally friendly material insulation hollow block produced by this ratio is 1030kg / m 3 , the thermal resistance is 1.18m 2 • K / W, the average compressive strength is 5.7MPa.

Embodiment 3

[0053] Embodiment 3, block raw material is as follows according to quality ratio:

[0054] 1 part of cement;

[0055] 0.366 parts of fly ash;

[0056] 1.382 parts of pumice coarse aggregate;

[0057] Iron tailings sand and pumice sand mixed fine aggregate 1.496 parts;

[0058] Admixture 0.006 parts;

[0059] 0.4 parts of water.

[0060] Iron tailings sand and pumice sand The mass ratio of iron tailings sand and pumice sand in the fine aggregate is 5:5.

[0061] After testing, the dry density of the new environmentally friendly material insulation hollow block produced by this ratio is 920kg / m 3 , the thermal resistance is 1.09m 2 ·K / W, the average compressive strength is 5.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com