Roller compacted concrete punching and slurry adding integrated device and roller compacted concrete punching and slurry adding method

A technology of roller compacted concrete and equipment, which is applied in the direction of stone processing equipment, stone processing tools, supply devices, etc., can solve the problems of slow construction progress, increased investment, and increased transportation equipment, and achieve high construction quality assurance and human resource input The effect of low cost and few construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

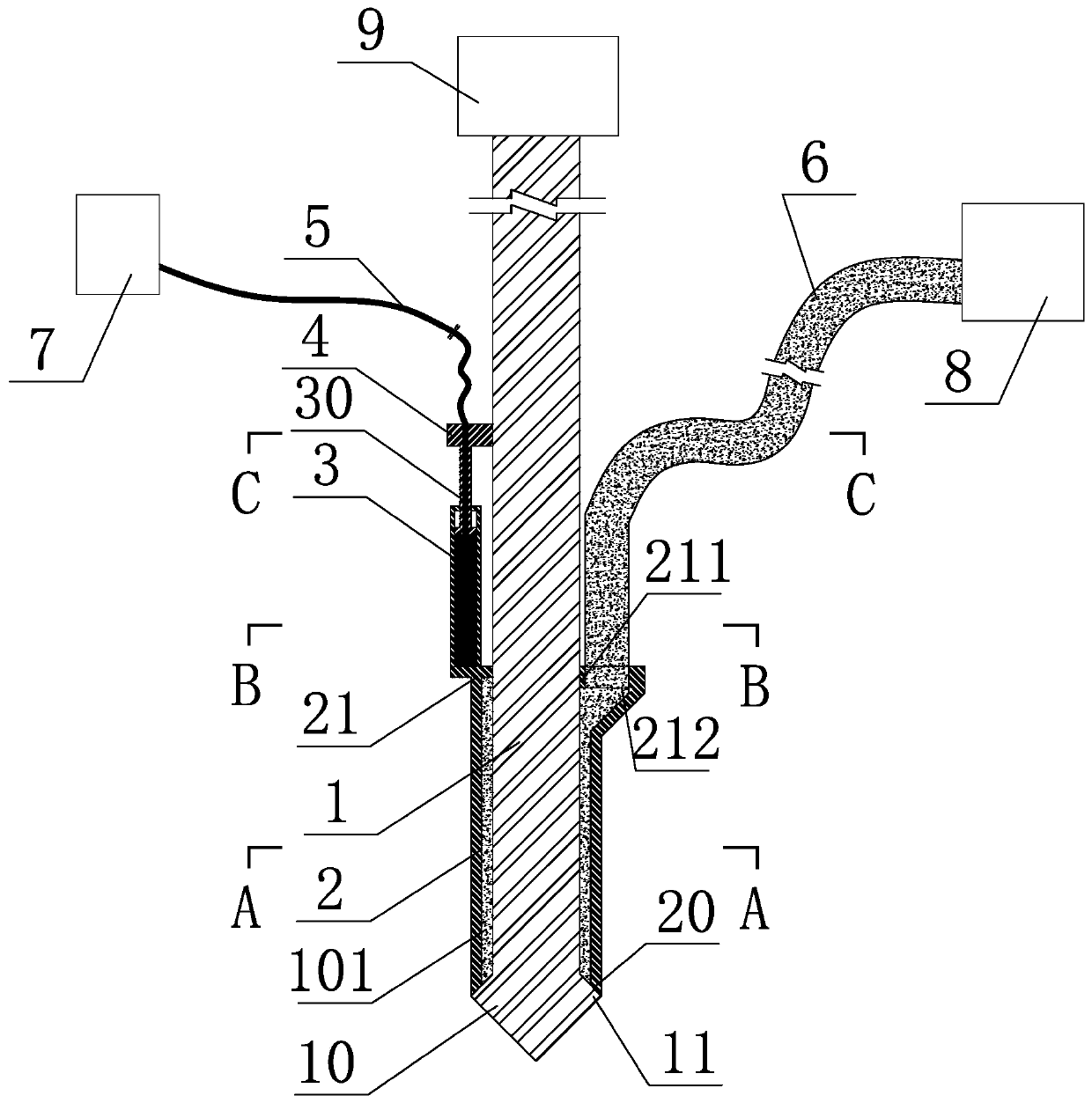

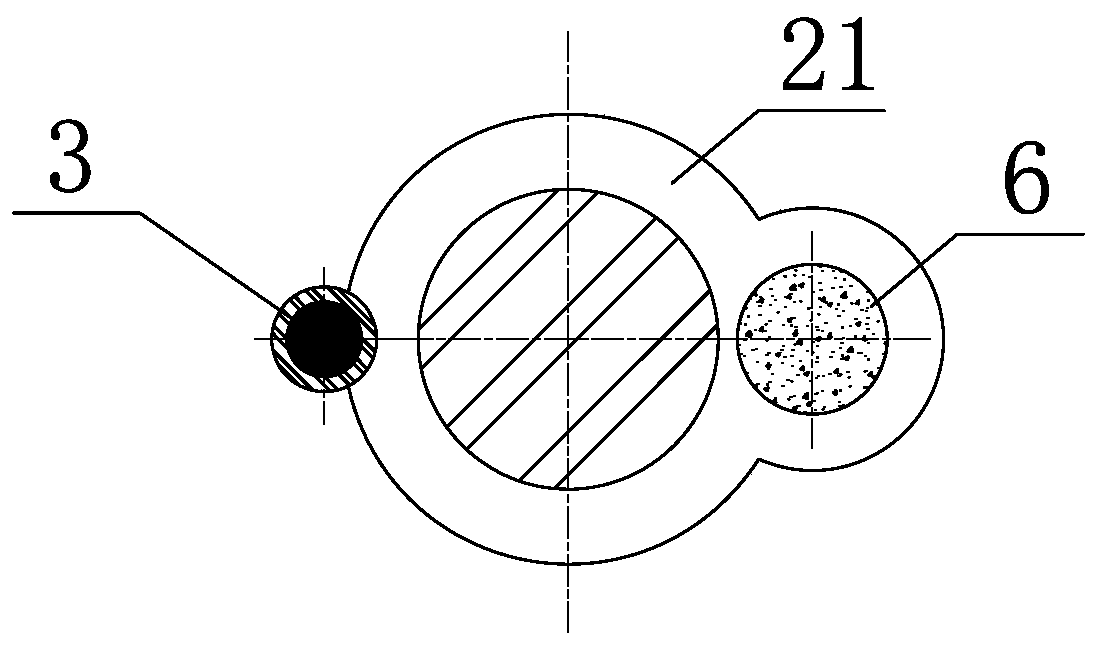

[0023] The invention mainly includes a punching rod 1 with a conical head 10, a grouting nozzle protective cover 2 and its lifting drive device, a grouting hose 6, a slurry storage and adding slurry equipment 8, and a drilling power equipment 9.

[0024] The slurry storage and slurry addition equipment 8 is used for storage and slurry addition of metamorphic concrete. The slurry storage and slurry addition equipment 8 is preferably equipment with quantitative grouting function.

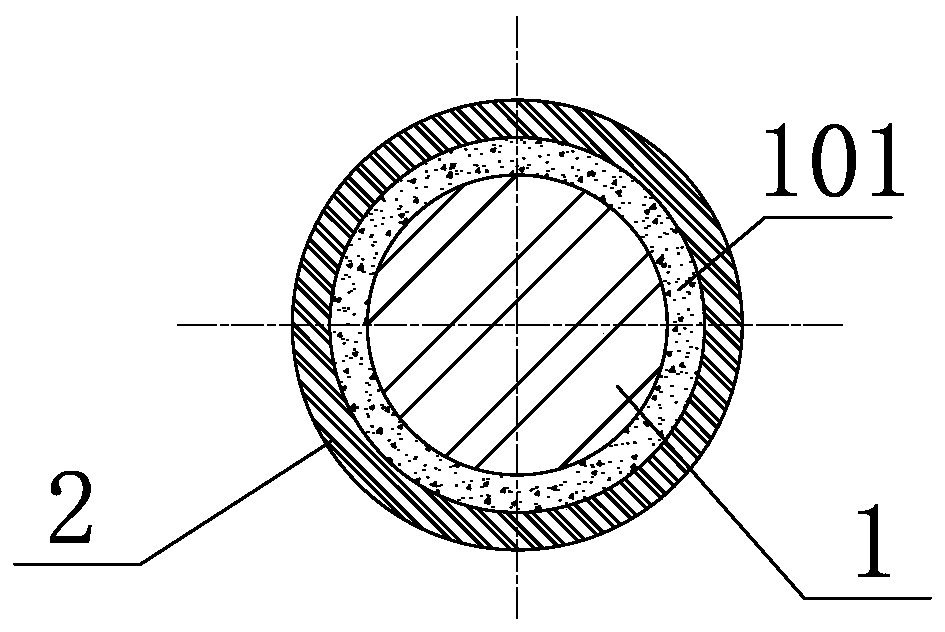

[0025] The sleeve part of the grouting nozzle protective sleeve 2 is set on the outside of the punching rod 1, and there is a certain gap 101 between the inner wall of the casing part of the grouting nozzle protection sleeve 2 and the punching rod 1 for grouting. The cone he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com