Industrialized development method for coal district coal-bed gas wells

A technology for coalbed methane wells and coal mines, applied in the field of industrialized development of coalbed methane wells in coal mining areas, can solve problems such as difficulties in commercial operation, difficulties in pipeline network collection and transportation, and limited promotion, achieving significant promotion and application value, perfecting theory and technology, reducing The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

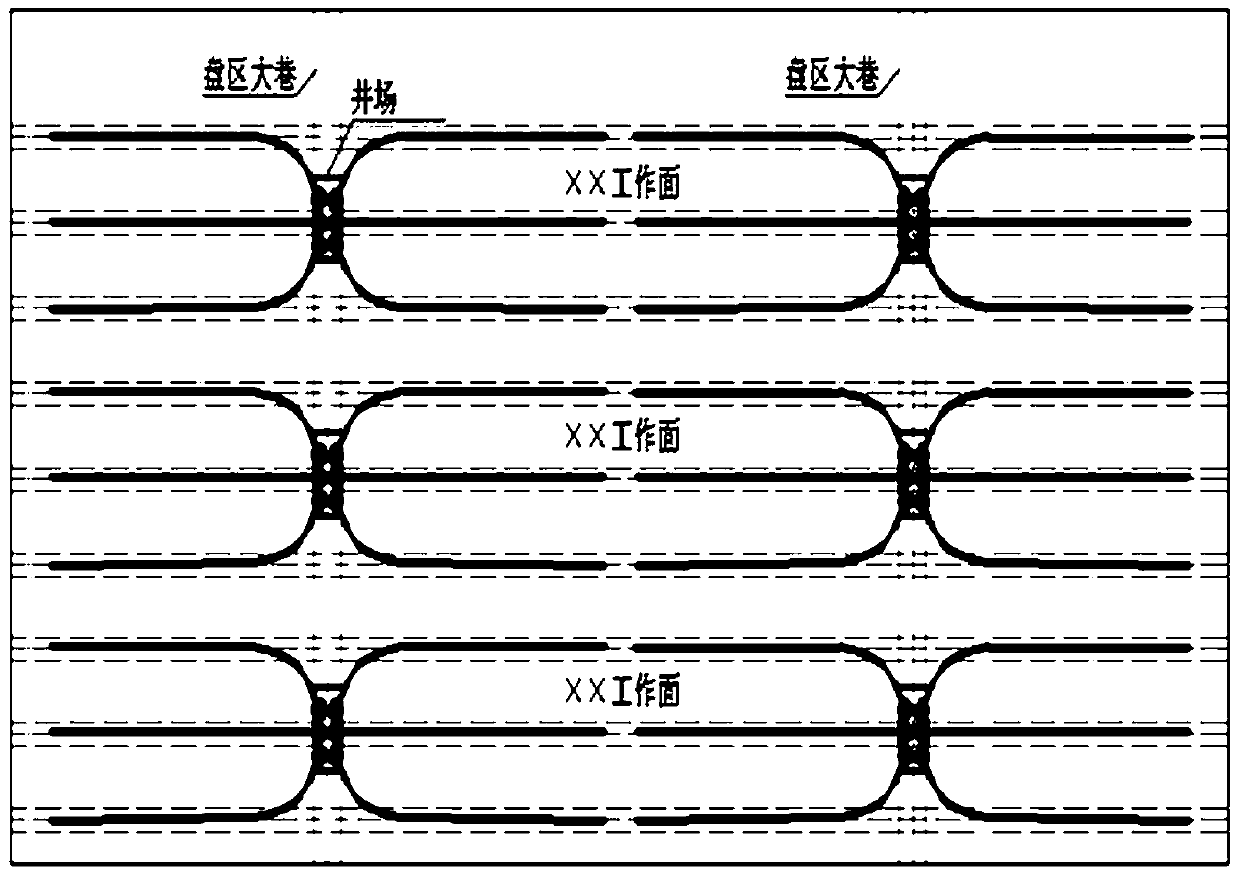

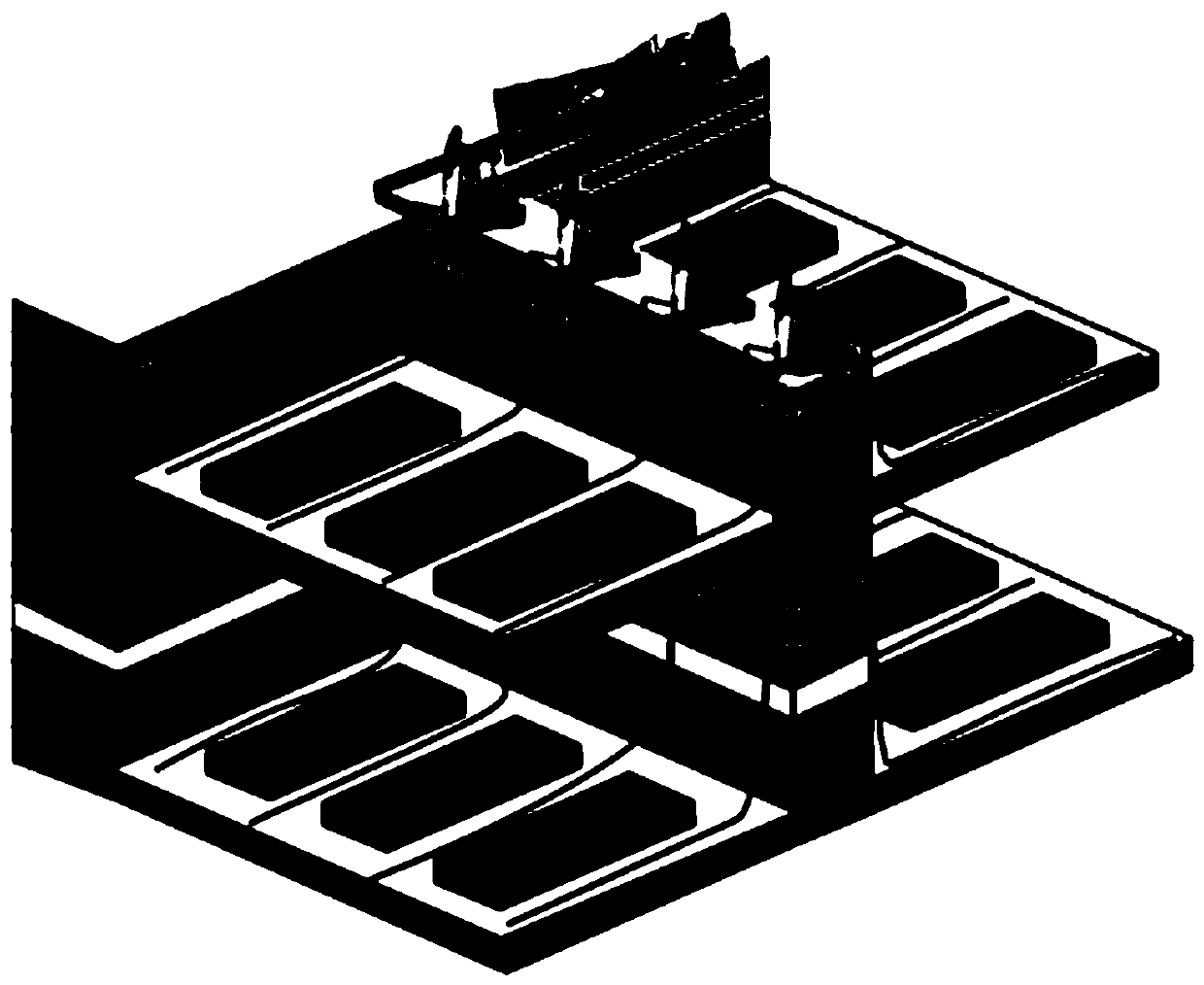

[0018] The method for industrialized development of coalbed methane wells in coal mining areas according to the present invention includes the optimization of well pattern of coalbed methane wells in coal mining areas, modular arrangement of coalbed methane wells and centralized operation, forming an integrated development of coalbed methane drilling-fracturing-drainage-gathering and transportation in coal mining areas Technology System.

[0019] (1) Optimization method of coalbed methane well pattern in coal mining area:

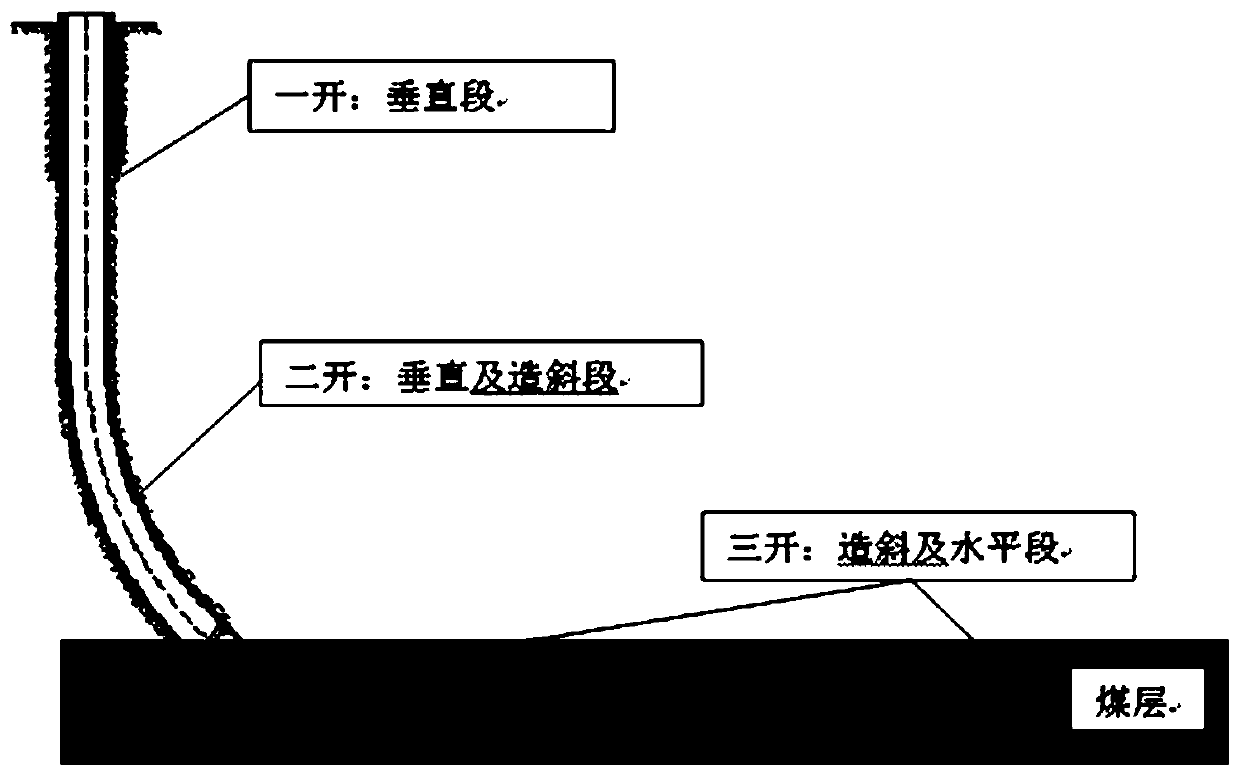

[0020] At present, the Jincheng mining area adopts the longwall mining face mining, the working face slope is 300m long, the strike is 1000-2000m long, and the roof is managed by the full caving method. According to the coal mine face design and excavation replacement deployment, and considering the coal fracture field, pressure field and stress field distribution and their coupling effects, "L-shaped" well development is adopted.

[0021] The "L-shaped" w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com