Steel pipe column concrete jacking construction method

A concrete roof and construction method technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems that cannot meet the requirements of green construction, cannot guarantee the compactness of concrete, and do not meet the requirements of green construction, and achieve obvious economic and social benefits , High construction efficiency and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

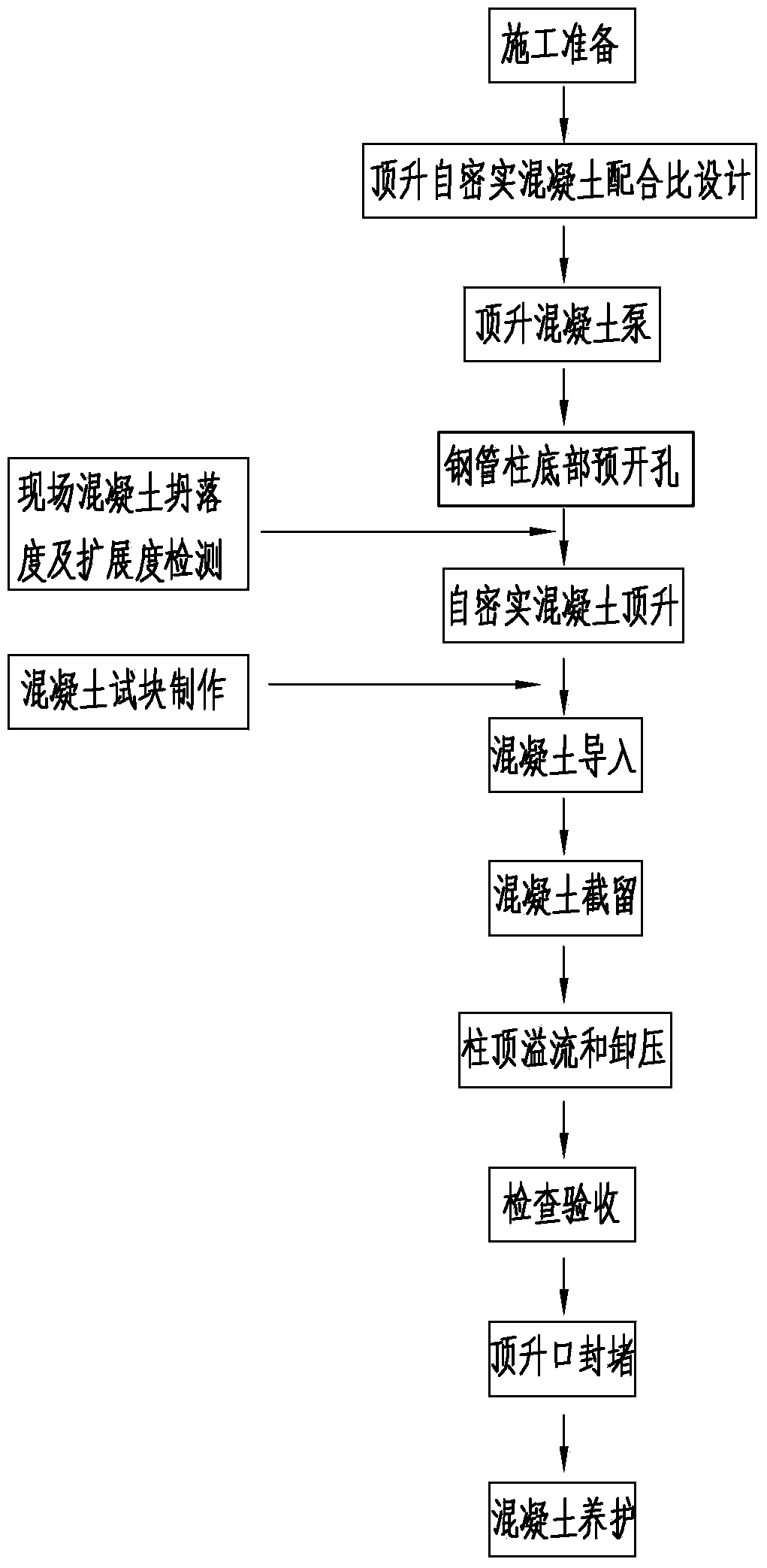

[0037] The invention discloses a concrete jacking construction method for a steel pipe column, the technological principle of which is to pre-embed a concrete conveying elbow at the base of the bottom of the steel pipe concrete column, and use ferrules to weld the stop valve with the concrete conveying pipe at both ends and the pre-embedded elbow and The concrete delivery pipe of the pump truck is connected, and the pressure of the concrete pump is used to squeeze and lift the self-compacting concrete from bottom to top into the steel pipe until the entire steel pipe concrete column is filled.

[0038] This construction method requires the following materials:

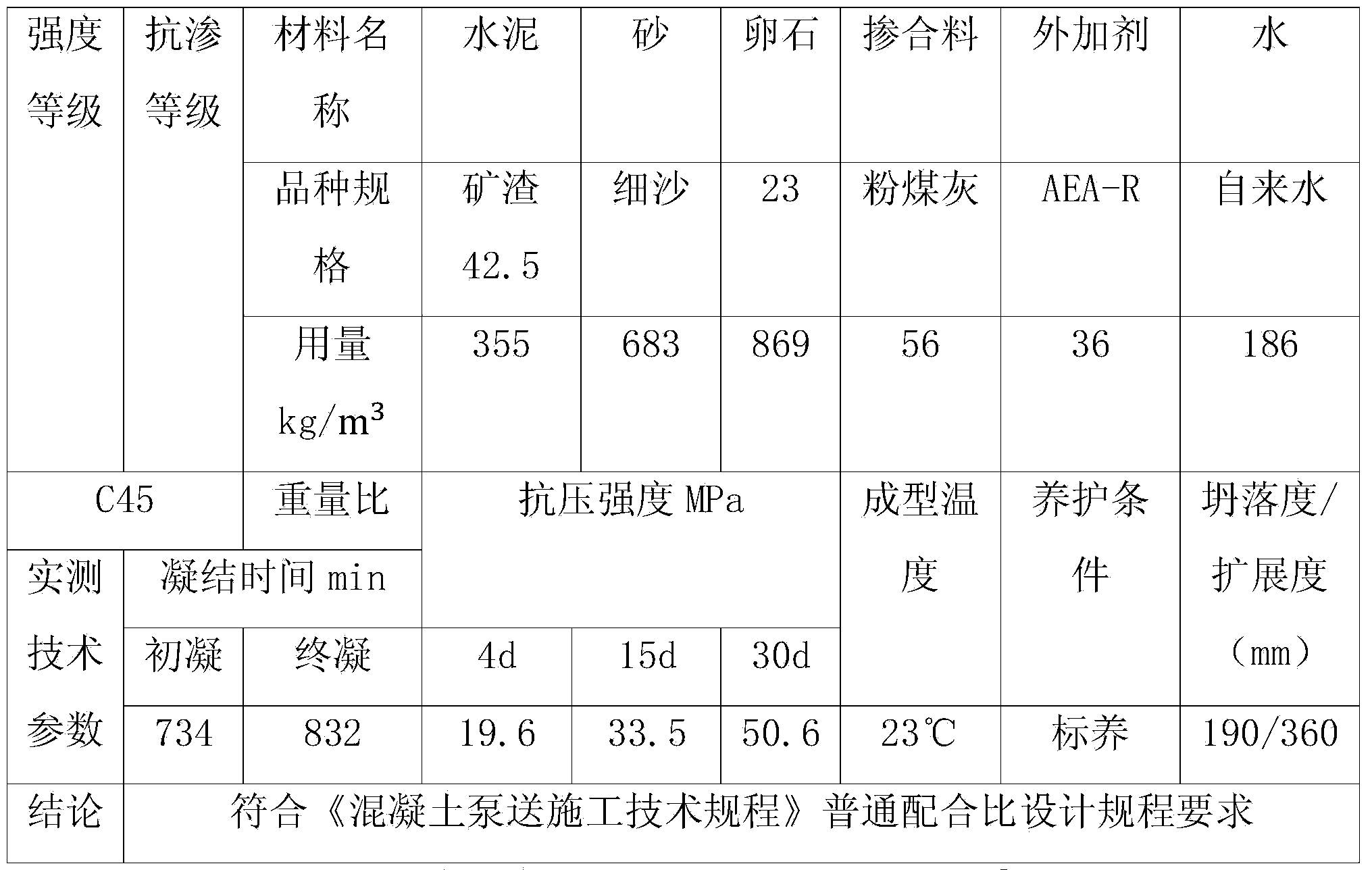

[0039] 1. 15mm thick Q235 steel plate, the coarse aggregate is pebbles with a particle size of 23mm, the fine aggregate is sand with a fineness modulus of 2.2 to 2.8, and the cement is 42.5 grade ordinary Portland cement with a water-cement ratio less than 0.4. Coal ash, appropriate amount of admixture, water reducer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com