Manufacturing and building method of heat preservation block (building plate) for inorganic self thermal insulation wall body

A technology of thermal insulation blocks and thermal insulation boards, applied in thermal insulation, walls, buildings, etc., which can solve the problems of poor fire prevention of inorganic materials, difficult construction, and poor fire performance, so as to enhance the effect of heat insulation and reduce engineering costs , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

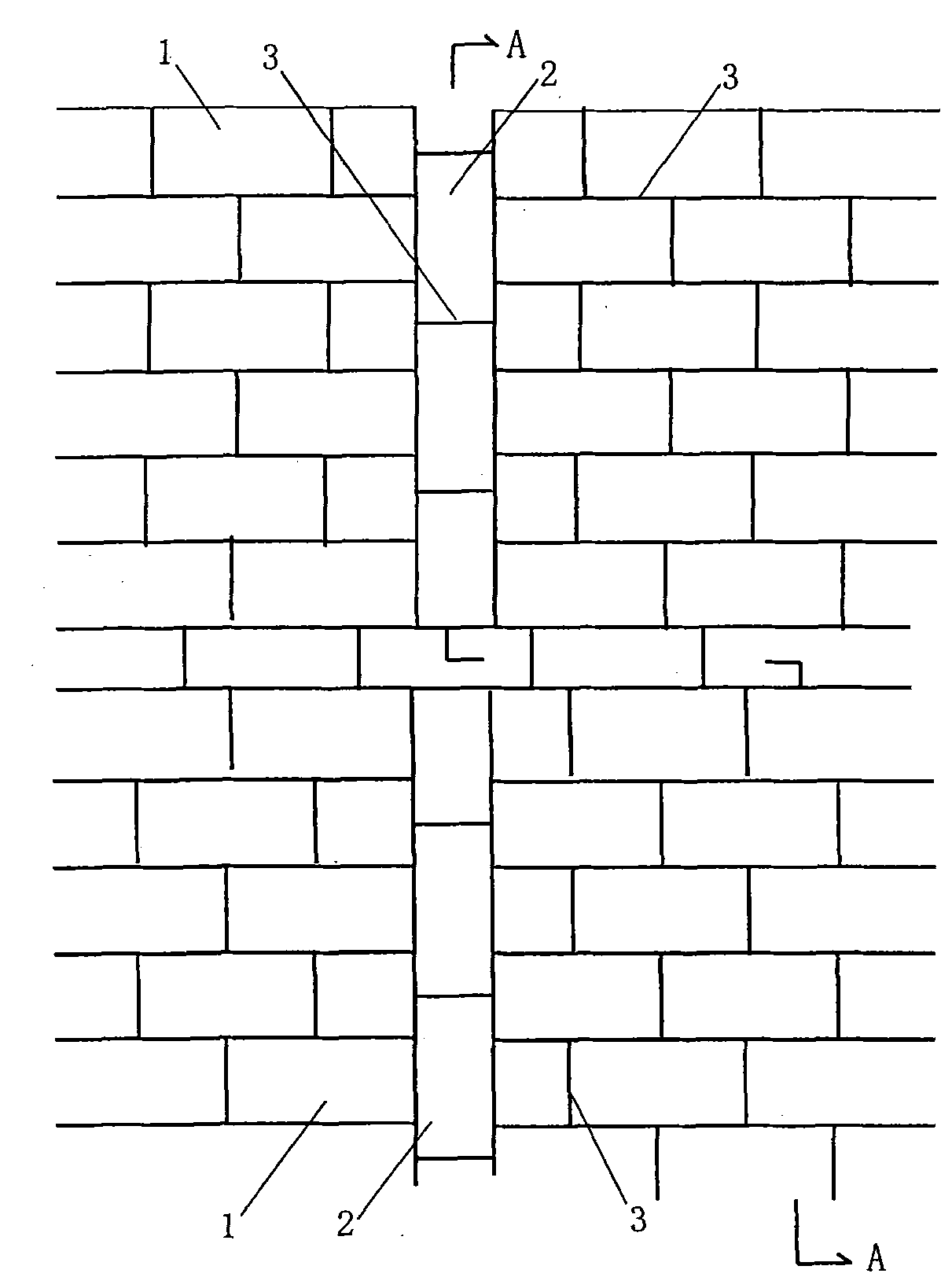

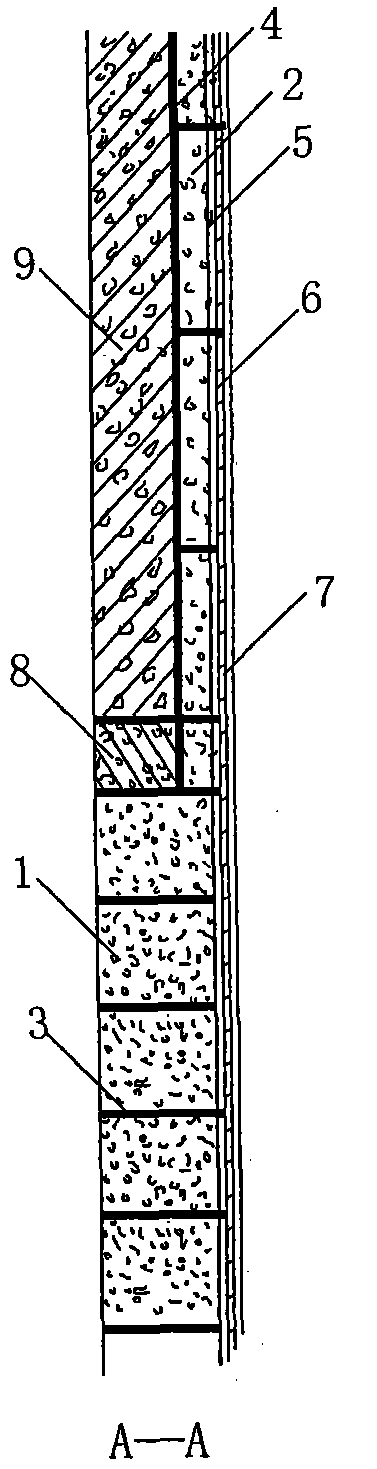

[0022] Such as figure 1 , figure 2 As shown, a method for making and building an inorganic self-insulating wall thermal insulation block (board) of the present invention includes a thermal insulation block 1 filling masonry, a thermal insulation board 2 inlaid and bonded, a masonry bonding joint 3, and a thermal insulation board Adhesive layer 4, mesh cloth adhesive layer 5, alkali-resistant mesh cloth layer 6, face protection layer 7, beam 8, column 9.

[0023] Such as image 3 , Figure 4 , Figure 5 Shown, a kind of inorganic self-insulation wall insulation block (board) making and masonry method of the present invention, insulation block 1 is cuboid shape. The specific size is determined according to the thickness of the wall design structure and the design requirements of the external wall heat transfer coefficient. The length or width of the thermal insulation block 1 is equal to the sum of the thickness of the building beam 8 or column 9 and the thickness of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com