Environmentally-friendly water-based two-component polyurethane coating and preparation method thereof

A water-based two-component, polyurethane coating technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of small molecular weight of hydroxyl components, easy bubbles in the paint film, long drying time, etc., and achieve good compatibility. , Guaranteed quality, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

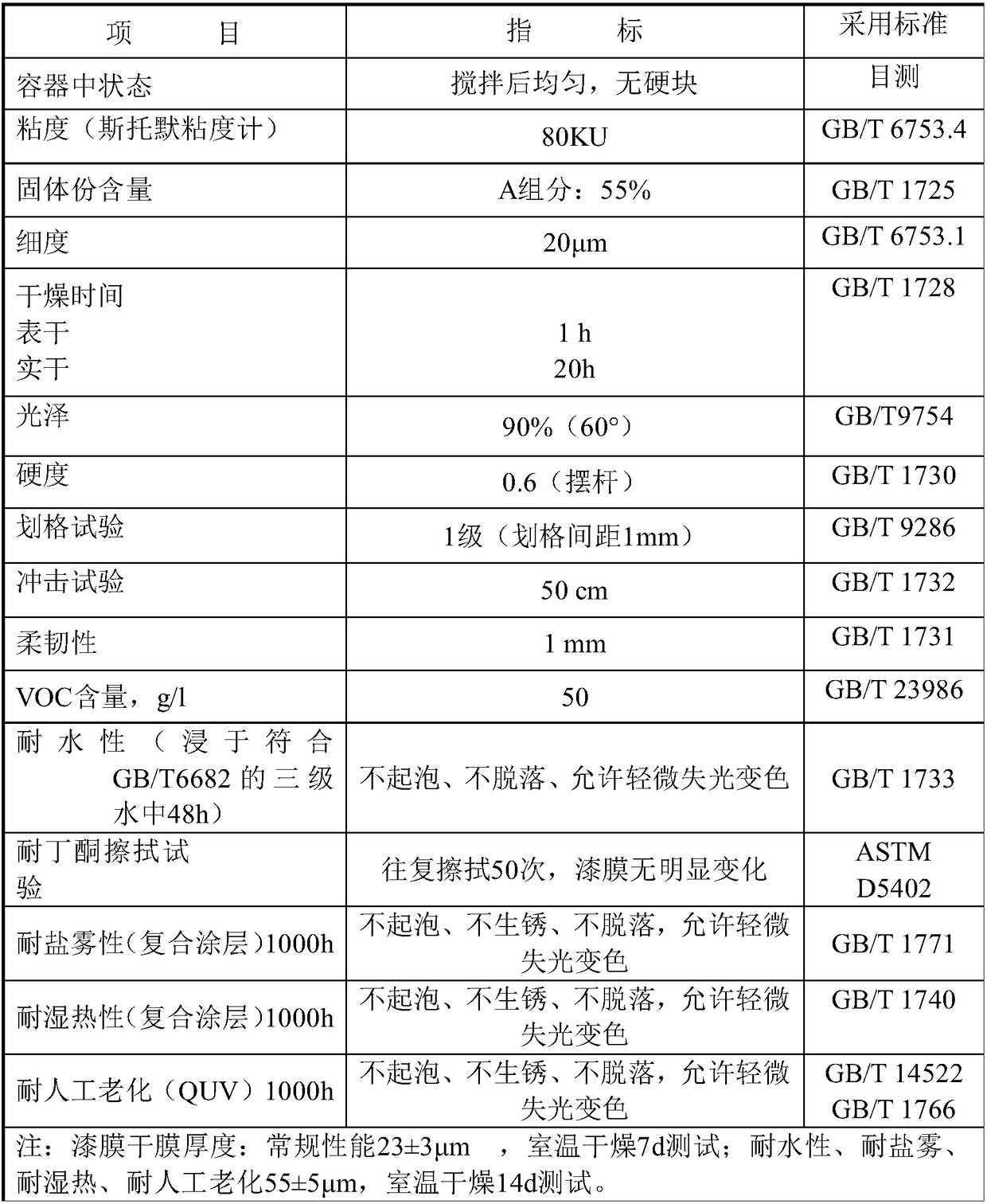

Examples

Embodiment 1

[0025] An environment-friendly water-based two-component polyurethane coating is composed of component A and component B, and the mass ratio of component A and component B is (2.7-3.0): (0.9-1.0).

[0026] The A component includes 35% to 40% of hydroxyacrylic acid dispersion I, 20% to 24% of hydroxyacrylic acid dispersion II, 0.2% to 1.0% of defoamer, and 2.0% to 3.0% of dipropylene glycol butyl ether in weight percentage , Ethylene glycol butyl ether 2.0% ~ 3.0%, leveling agent 0.2% ~ 1.0%, color paste 15% ~ 38%, thickener 0.1% ~ 0.3%;

[0027] The B component includes 30%-33% of propylene glycol diacetate, 43%-49% of polyurethane curing agent I and 18%-24% of polyurethane curing agent II by weight percentage.

[0028] The present invention uses water-based hydroxyacrylic resin as the base material, and adds pigments with excellent weather resistance, additives (defoamers, leveling agents, thickeners) and cosolvents (dipropylene glycol butyl ether, ethylene glycol butyl ether...

Embodiment 2

[0030] On the basis of Example 1, the hydroxyl content in the hydroxyacrylic acid dispersion I is 3.0-3.8wt%, and the non-volatile content is 45-50wt%; for example, the A2470 hydroxyacrylic acid dispersion produced by Covestro Technology Co., Ltd. , 2033 hydroxyacrylic acid dispersion produced by Wanhua Chemical Group Co., Ltd.; the hydroxyl content in the hydroxyacrylic acid dispersion II is 3.8-4.1wt%, and the non-volatile content is 45-50wt%. The A2646 hydroxyacrylic acid dispersion produced by the company and the 5286 hydroxyacrylic acid dispersion produced by Shanghai Huarong Chemical Co., Ltd.

[0031] The hydroxyacrylic dispersion I can provide excellent gloss, chemical resistance and weather resistance; the hydroxyacrylic dispersion II can provide excellent gloss and mechanical properties, while having outstanding water resistance.

[0032] The defoamer is a polysiloxane hydrophobic particle defoamer with a non-volatile content>98wt%, such as BYK-022 (industrial grade ...

Embodiment 3

[0039] On the basis of above-mentioned embodiment, the preparation method of described environment-friendly type waterborne two-component polyurethane coating comprises the following steps:

[0040] 1) Preparation of component A:

[0041] Firstly, according to the requirements of the operation instructions and internal control indicators, check and accept WPU color pastes of various colors. The acceptance items include: quantity, color, fineness, viscosity, solid content, etc., and then add the formulated amount of hydroxyacrylic dispersion Ⅰ and hydroxyacrylic dispersion Ⅱ Put into a clean tank, add the formula amount of color paste under stirring conditions, after stirring evenly, then add the formula amount of defoamer, dipropylene glycol butyl ether (DPNB), ethylene glycol butyl ether (EB) and leveling agent, stir for 10-20 minutes, and finally add the thickener of the formulated amount to adjust the viscosity, and stir evenly to obtain component A in the environmentally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com