High-temperature-resistant high-pressure-resistant water-based wood paint and preparation method thereof

A water-based wood paint, high temperature resistance technology, applied in the direction of coating, etc., can solve the problems of inability to resist high temperature and high pressure, and achieve the effects of avoiding economic losses, high solid content, and saving baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

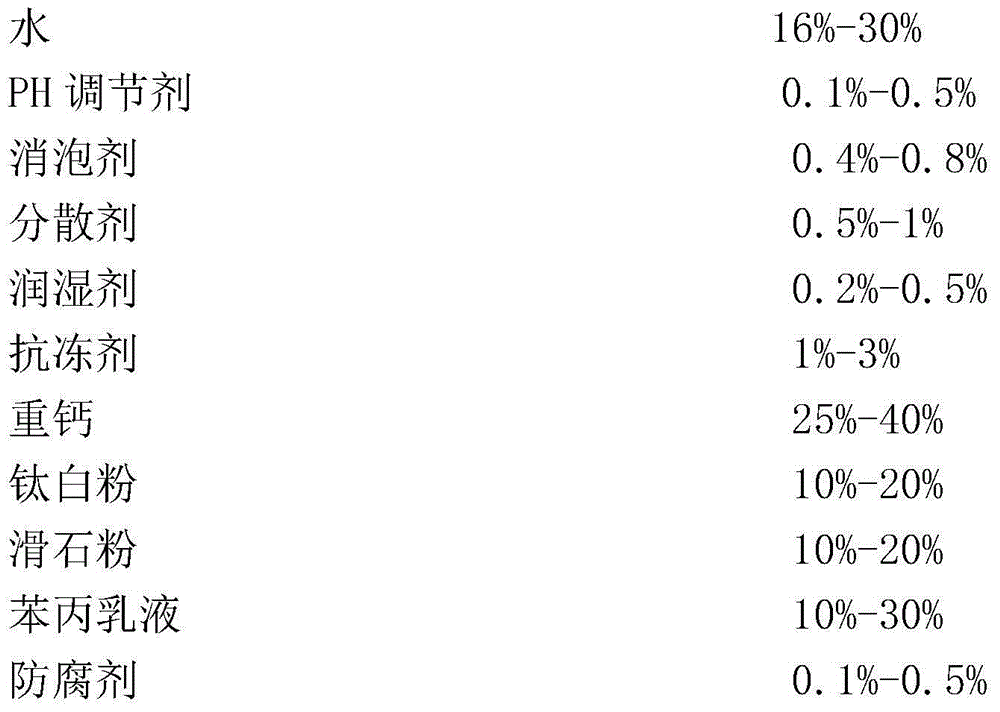

[0022] A high-temperature, high-pressure-resistant water-based wood paint, the high-temperature, high-pressure water-based wood paint includes the following components, each component and its weight percentage are as follows:

[0023]

[0024] Thickeners include Aqualone hydroxyethyl cellulose 250HBR at 0.2%-0.5% by weight, Rohm and Haas thickener ASE60 at 0.5%-1% by weight and 0.3%-1% by weight of Rohm and Haas thickener RM8W.

[0025] Water is deionized water, the pH regulator is Angus pH regulator AMP95, the defoamer is Henkel NXZ defoamer, the dispersant is Nopco SN5040 dispersant, the wetting agent Clariant D2366 wetting agent, the antifreeze agent is propylene glycol, the heavy calcium is Sannong heavy calcium 1200, the titanium dioxide is Baiyuying brand rutile titanium dioxide HTR-668, and the talcum powder is Longsheng Huamei 1250 mesh talcum powder, the styrene-acrylic emulsion is Yizhong Industrial styrene-acrylic emulsion ER98, the preservative is Thor preserva...

Embodiment 2

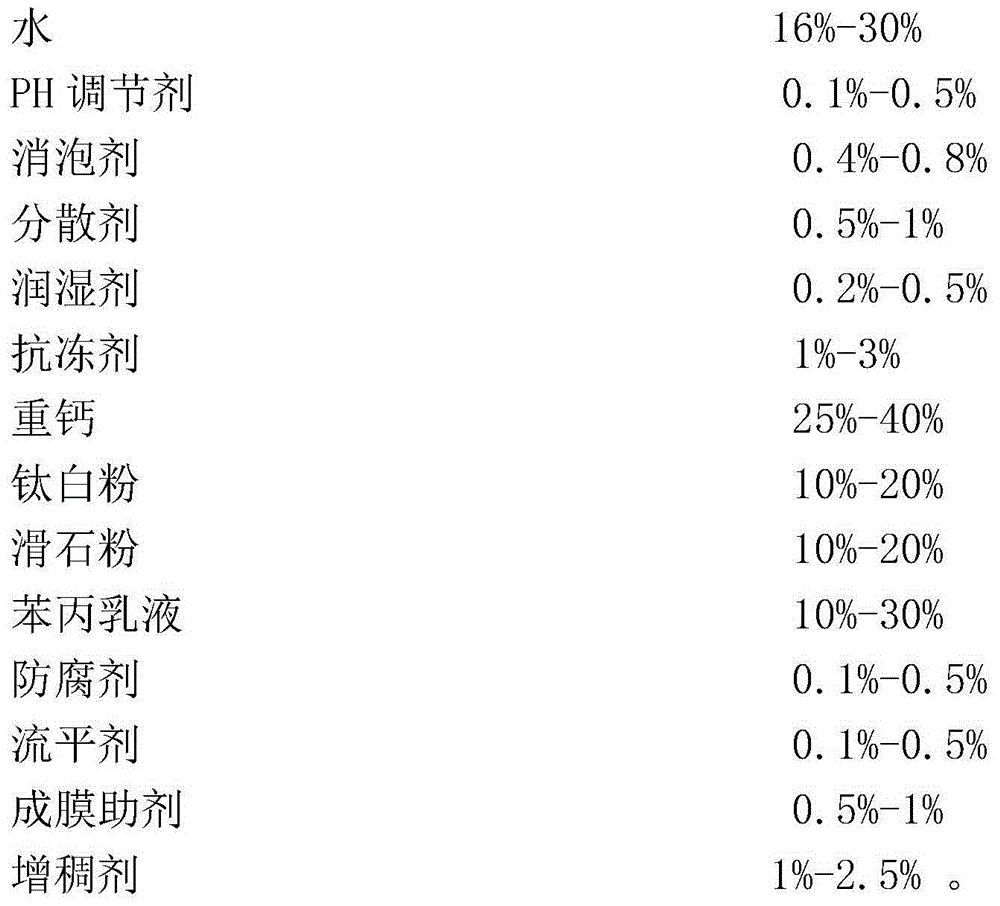

[0037] A high-temperature, high-pressure-resistant water-based wood paint, the high-temperature, high-pressure water-based wood paint comprises the following components, each component and its weight percentage are as follows:

[0038]

[0039]

[0040] The water is deionized water, the pH regulator is Angus pH regulator AMP95, the defoamer is Henkel NXZ defoamer, the dispersant is Nopco SN5040 dispersant, and the wetting agent The wetting agent is Clariant D2366 wetting agent, the antifreeze agent is propylene glycol, the heavy calcium is Sannong heavy calcium 1200, the titanium dioxide is Baiyuying brand rutile titanium dioxide HTR-668, and the talcum powder is Longsheng Huamei 1250 mesh talcum powder, the styrene-acrylic emulsion is Yizhong Industrial styrene-acrylic emulsion ER98, the preservative is Thor preservative R-S; the leveling agent is Xin’an Industrial leveling agent XHG248, and the film-forming aid The agent is dipropylene glycol butyl ether.

[0041] A k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com