Strong absorptive dope of restraining frost

A strong water-absorbing, coating technology, applied in anti-fouling/underwater coatings, coatings, defrosting, etc., can solve problems such as unsatisfactory coating thickness, poor impact resistance, and inconspicuous anti-frost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The production steps of anti-frost coating are as follows:

[0025] 1. Production of water-absorbent resin (refer to the general process of making water-absorbent resin):

[0026] The composition of the water-absorbing resin is as follows by mass: acrylic acid 49, acrylamide 10, water 160, potassium hydroxide 20, sodium hydroxide 5, hydroxypropyl methacrylate 7, N,N'-methylenebisacrylamide 0.002, initiation Agent (ammonium persulfate) 0.04, sodium bisulfite 0.05.

[0027] According to the above formula, add water, potassium hydroxide and sodium hydroxide into the reactor with reflux condenser, dropping funnel nitrogen conduit, and add acrylic acid and N,N'-methylenebispropylene under the condition of nitrogen gas. Amide, add hydroxypropyl methacrylate while stirring, and keep the temperature at 40°C. Add acrylamide, add ammonium persulfate initiator and sodium bisulfite in 4 times. It was heated to 60° C. and allowed to stand for 6 hours for polymerization reaction. The mix...

Embodiment 2

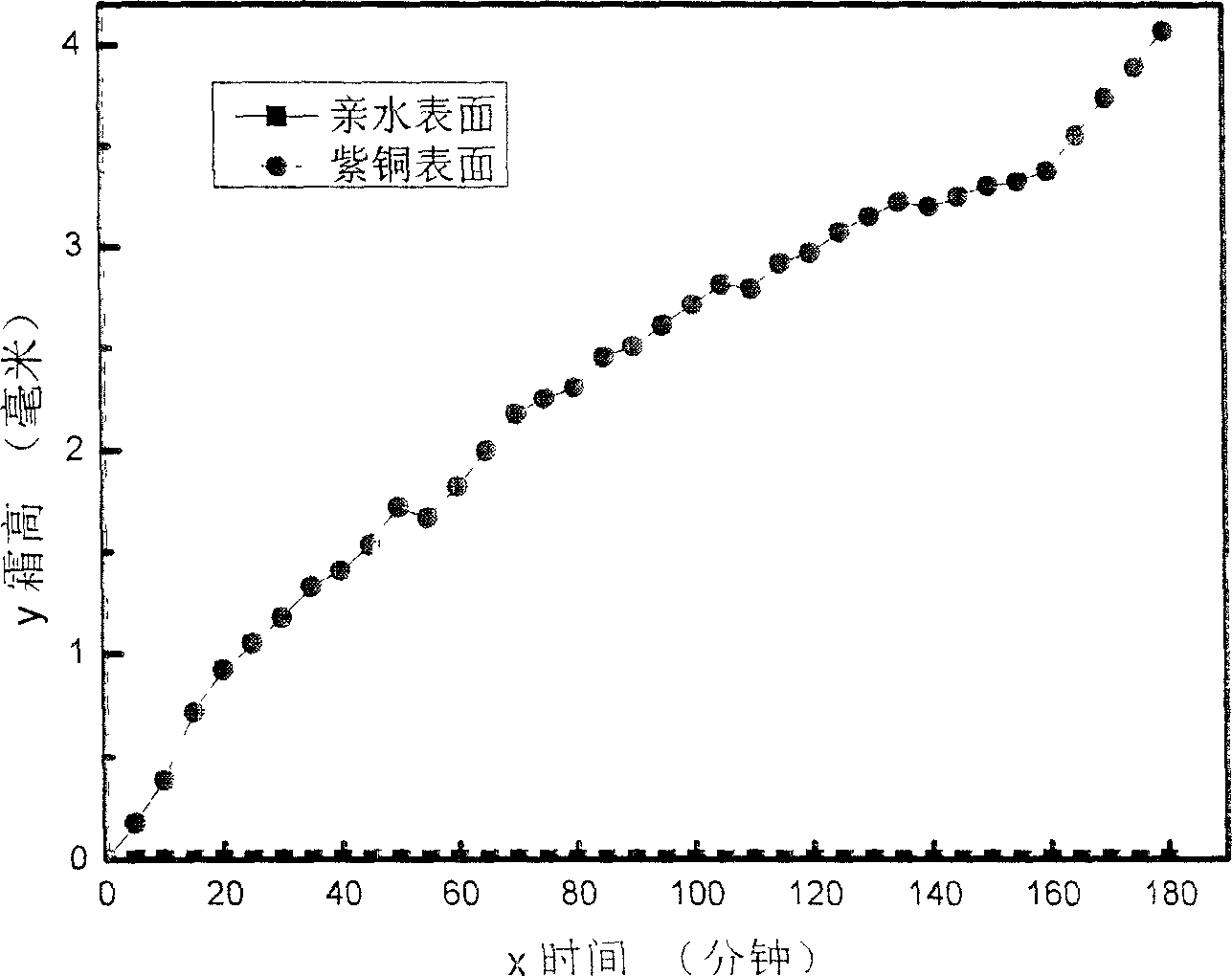

[0043] The composition of the water-absorbing resin is shown in Table 1, and the manufacturing process is the same as in Example 1. Weigh 20 grams of water-absorbent resin, 40 grams of polyurethane baking varnish, 30 grams of calcium chloride, and 30 grams of 200# gasoline. After mixing, stir thoroughly and spray the mixture on the inner wall of the refrigerator with a spray gun. Figure 7 A comparison of the amount of frost on the inner wall surface of the refrigerator coated with the strong water-absorbing frost-inhibiting paint of the present invention and the bare inner wall surface without any paint after the refrigerator has been operated for six months. The left side is the hydrophilic surface, and the right side is the bare surface of the inner wall of the refrigerator. The environmental conditions are T∞=-30.6°C, Tw=-34.0°C, and φ=80%. It can be seen from the picture that a thick layer of frost has formed on the bare surface of the inner wall of the refrigerator on the rig...

Embodiment 3,4

[0045] Table 1 lists the components of the anti-frost coating in Examples 3, 4, and 5 respectively. The production process and test equipment of the super absorbent resin and the anti-frost coating are the same as those in Example 1. The examples are also listed in Table 1. The components of 1, 2 and the test effects of 5 examples.

[0046] It is measured in the experiment that when the air humidity is less than 75%, the wall temperature is more than -20°C, and the ambient temperature is 20°C, the surface coated with the strong water-absorbing anti-frost coating of the present invention can keep the initial frost crystals at least After a delay of more than 3 hours, the frost suppression effect is quite obvious, as shown in Examples 1, 3, 4 and 5 in the table. In addition, the longest measurement time for the frost suppression experiment of the strong water-absorbent frost-inhibiting paint is six months. Using the actual running refrigerator as the experimental environment, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com