Environmentally-friendly high-performance water-based woodware paint and using method thereof

A water-based wood paint, high-performance technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of hardness, fullness, insufficient chemical resistance, slow drying, two-component design, inconvenient use, etc. Achieve the effect of ensuring film-forming performance, good drying, and excellent quick-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

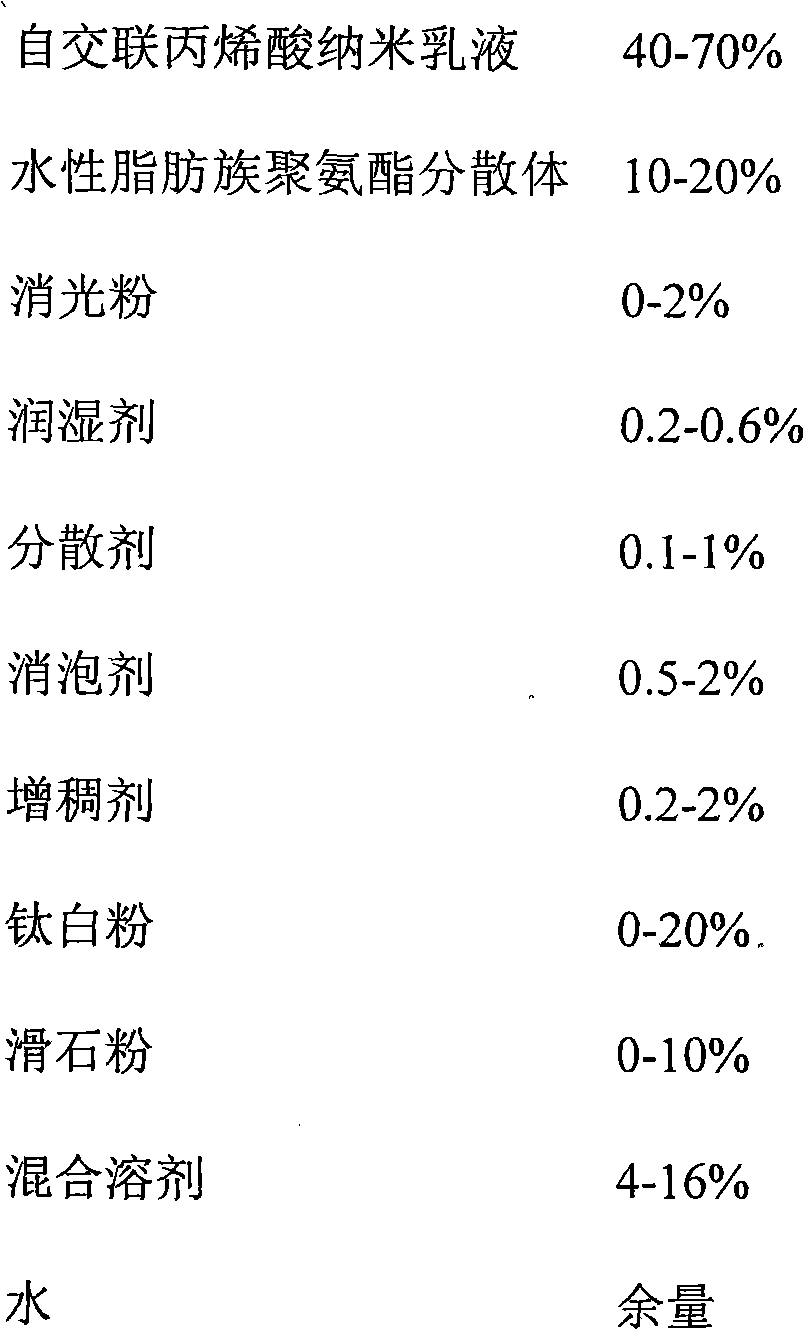

[0025] formula:

[0026]

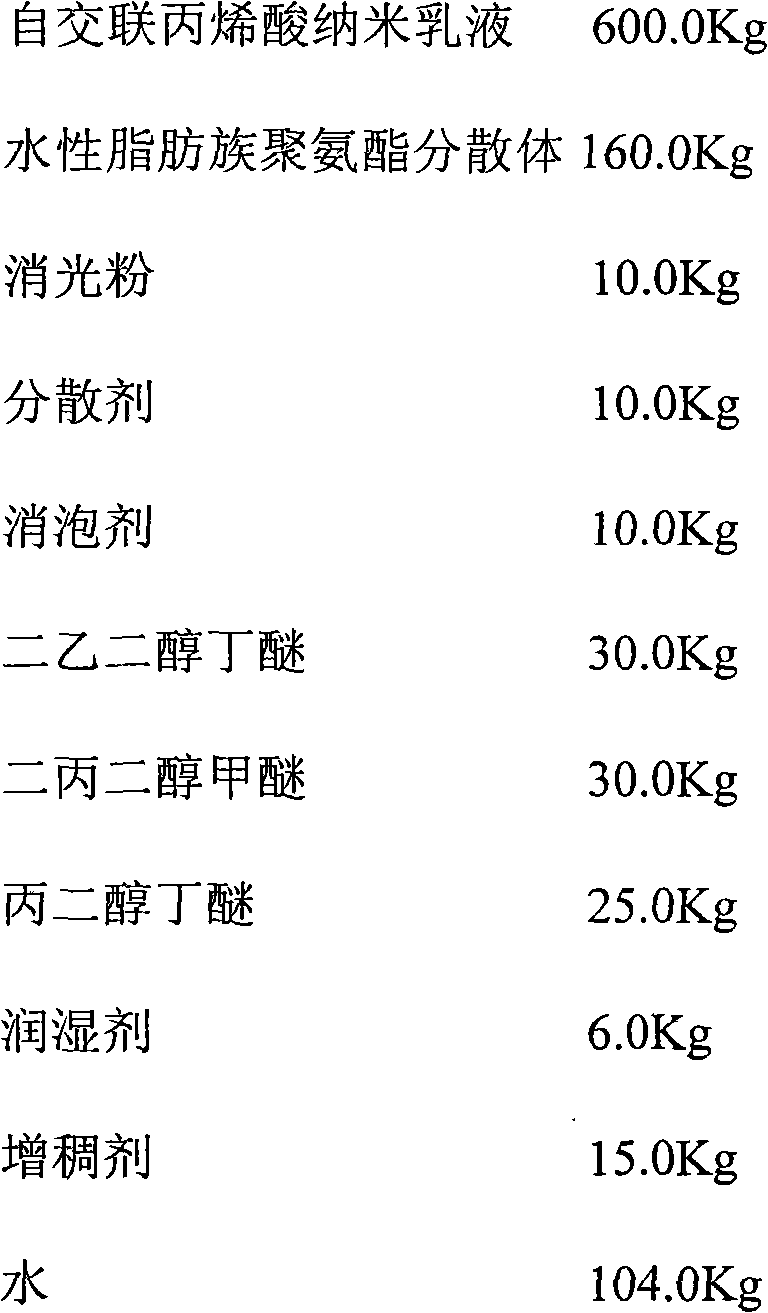

[0027] The self-crosslinking acrylic nanoemulsion uses AC2514 from Alberdingk, Germany;

[0028] The waterborne aliphatic polyurethane dispersion adopts CUR995 from Alberdingk, Germany;

[0029] The matting powder is OK-412 from Germany Degussa Company;

[0030] The dispersant is Hydropalat 1080 from Cognis, Germany;

[0031] The defoamer is BYK-028 from BYK Company in Germany;

[0032] The wetting agent is wet KL245 from Tego Company of Germany;

[0033] The thickener is ACRYSOL RM-8W from American ROHM HAAS Company.

[0034] Put the self-crosslinking acrylic nanoemulsion and water-based aliphatic polyurethane dispersion into the disperser and stir evenly, add matting powder, dispersant, defoamer, and disperse at a line speed of 20m / s for 30 minutes to a fineness of 25μm or below. Continue to add diethylene glycol butyl ether, dipropylene glycol methyl ether, propylene glycol butyl ether, wetting agent, thickener, water, and stir well to obt...

Embodiment 2

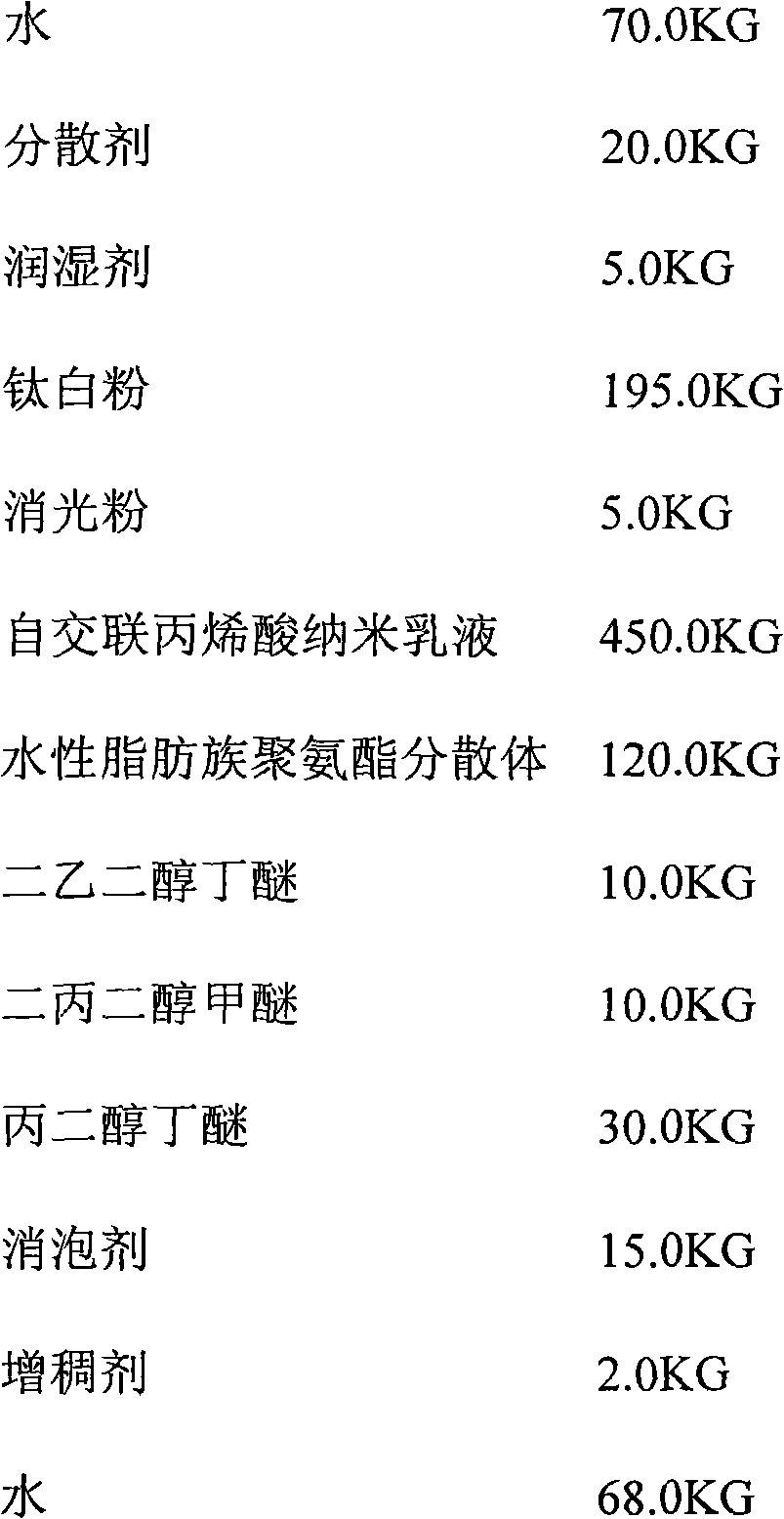

[0039] formula:

[0040]

[0041] The self-crosslinking acrylic nanoemulsion adopts 3188 from ROHM HAAS Company of the United States;

[0042] The water-based aliphatic polyurethane dispersion adopts CUR99 from Alberdingk, Germany;

[0043] The matting powder is SD530 from China Aerospace Saide Company;

[0044] The dispersant is Hydropalat 1080 from Cognis, Germany;

[0045] The defoamer is Foamex 810 from Germany Tego Company;

[0046] The wetting agent is wet KL245 from Tego Company of Germany;

[0047] The thickener is visco plus 3030 from German Tego Company;

[0048] Titanium dioxide is selected from R-706 of Dupont Company of the United States.

[0049] Add 70KG water, 20KG dispersant and 5KG wetting agent into a 2000 liter high-speed disperser and stir evenly, add 195KG titanium dioxide and 5KG matting powder under stirring, and disperse at a high speed of 20m / s for 25-40 minutes to Fineness 25μm or below, add 450KG self-crosslinking acrylic nanoemulsion and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com