Real-stone paint and preparation method thereof

A technology of real stone paint and lacquer vat, which is applied in the field of building decoration materials, can solve the problems of affecting the coating construction quality and decorative effect, affecting the coating appearance and decorative effect, and poor stain resistance, so as to facilitate water volatilization and water retention Reduce, reduce the effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

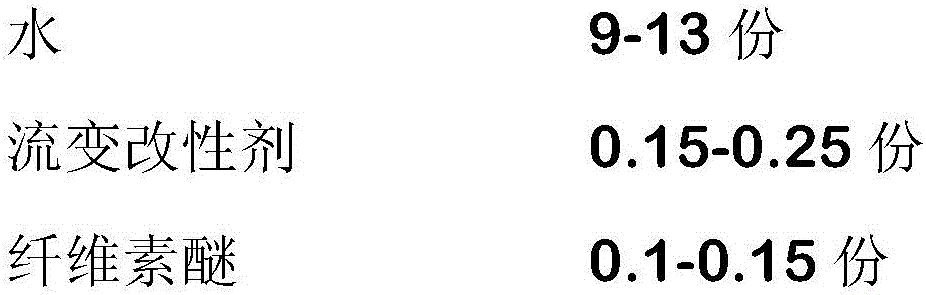

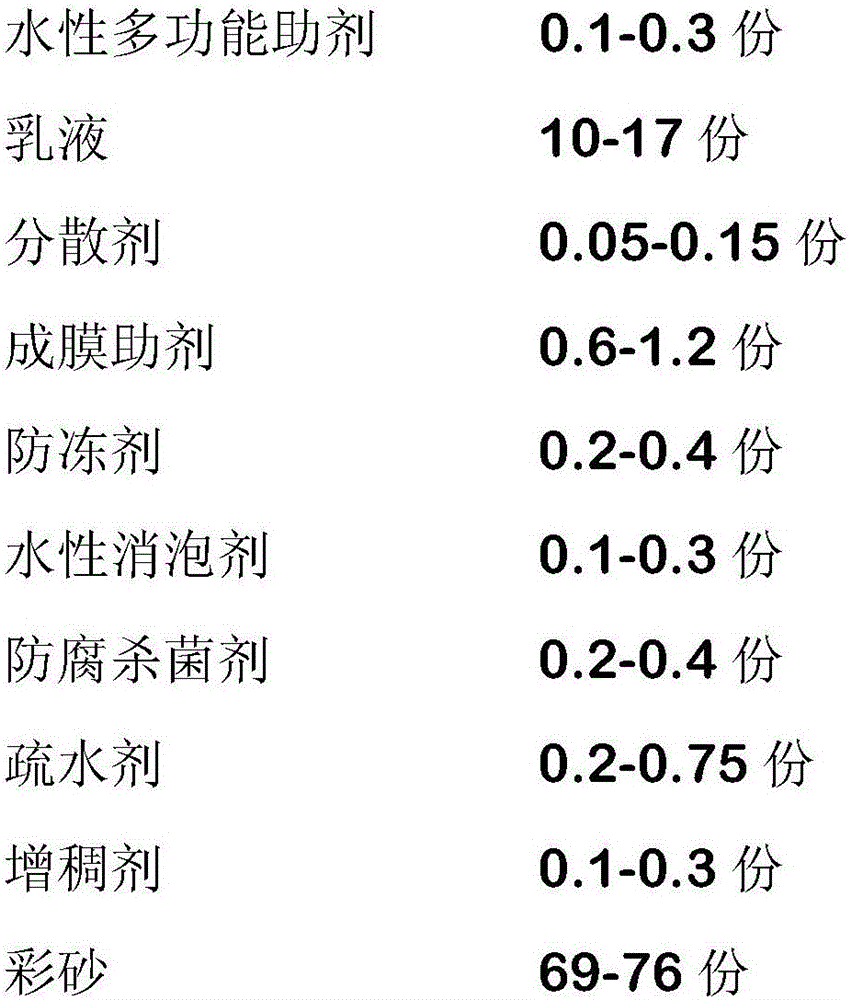

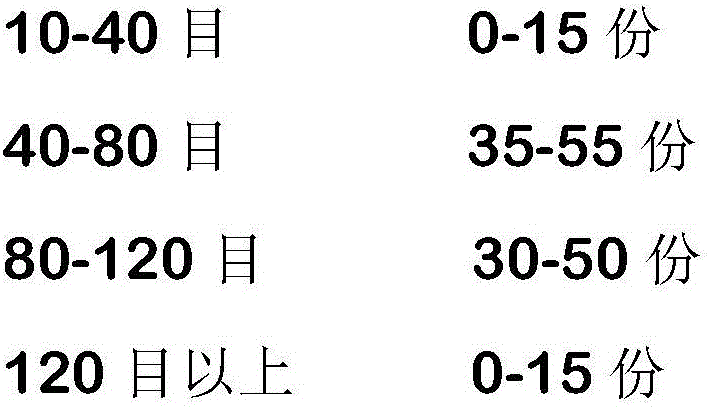

[0036] A kind of real stone paint, which is prepared from the following components and parts by weight ratio:

[0037]

[0038]

[0039] A method for preparing above-mentioned real stone paint, it comprises the following steps carried out in sequence:

[0040] (1) Put 9 parts of water into a clean paint tank, start the disperser, stir and disperse at a linear speed of 3m / s~6m / s;

[0041] (2) Add 0.15 parts of rheological agent, stir and disperse for 8-10 minutes at a linear speed of 3m / s~6m / s;

[0042] (3) Add 0.1 part of cellulose ether, stir and disperse for 5-8 minutes at a linear speed of 3m / s-6m / s;

[0043] (4) When the cellulose ether is completely wetted and stirred evenly, add 0.15 parts of water-based multifunctional additives to adjust the pH to 8.0-10.0, and stir and disperse at a linear speed of 10m / s-15m / s for 5-8 minutes;

[0044] (5) Put in 15.5 parts of pure acrylic emulsion, stir and disperse for 8-10 minutes at a linear speed of 6m / s~10m / s;

[0045] ...

Embodiment 2

[0050] A kind of real stone paint, which is prepared from the following components and parts by weight ratio:

[0051]

[0052] A method for preparing above-mentioned real stone paint, it comprises the following steps carried out in sequence:

[0053] (1) Put 10 parts of water into a clean paint tank, start the disperser, stir and disperse at a linear speed of 3m / s~6m / s;

[0054] (2) Add 0.15 parts of rheological agent, stir and disperse for 8-10 minutes at a linear speed of 3m / s~6m / s;

[0055] (3) Add 0.1 part of cellulose ether, stir and disperse for 5-8 minutes at a linear speed of 3m / s-6m / s;

[0056] (4) When the cellulose ether is completely wetted and stirred evenly, add 0.15 parts of water-based multifunctional additives to adjust the pH to 8.0-10.0, and stir and disperse at a linear speed of 10m / s-15m / s for 5-8 minutes;

[0057] (5) Put in 12 parts of styrene-acrylic emulsion, stir and disperse for 8-10 minutes at a linear speed of 6m / s-10m / s;

[0058] (6) Add 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com