Cloth fragrant granule and preparation method thereof

A kind of fragrance and granule technology, which is applied in the direction of washing composition fragrance, organic washing composition, etc., can solve the problems of high cost, low dissolution rate, unsuitable for hand washing and other laundry washing fragrance additives, and achieve low cost and good fragrance retention , good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] What this embodiment adopts is the existing technology that uses polyethylene glycol and water-soluble salt as the carrier, and the components and contents are shown in Table 1. The preparation steps of the clothing fragrance granules are as follows:

[0051] (1) Add polyethylene glycol into a stirring pot, heat to 80°C, and stir until it becomes a transparent liquid;

[0052] (2) Add the pigment into the mixing pot and stir evenly;

[0053] (3) Add water-soluble salt and stir to disperse evenly;

[0054] (4) Add liquid essence, hydrophobic resin-wrapped essence, and pigment and stir for 20 minutes;

[0055] (5) Pass the mixture in the molten state in the stirring pot into the melting granulation equipment for granulation. The shape of the granulation is hemispherical and the average particle size is 0.3cm. After the granules are solidified and cooled, they are packaged.

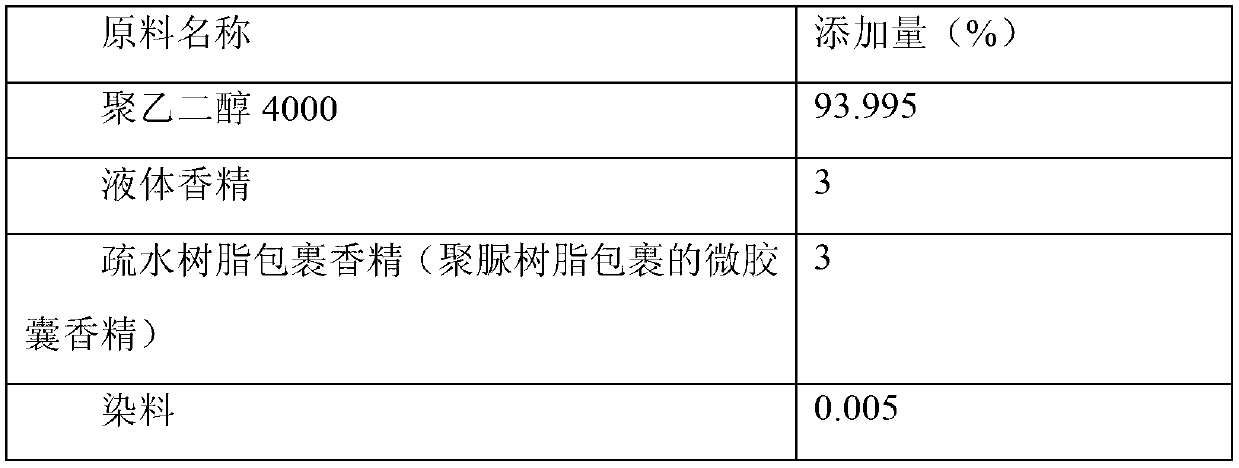

[0056] The composition of the clothing fragrance granule of table 2 embodiment 1

[0057]

Embodiment 2

[0059] What this embodiment adopts is the improved technology that uses polyethylene glycol and water-soluble salt as the carrier, and the components and contents are shown in Table 3. The preparation steps of the clothing fragrance granules are as follows:

[0060] (1) Add polyethylene glycol into a stirring pot, heat to 80°C, and stir until it becomes a transparent liquid;

[0061] (2) Add the pigment into the mixing pot and stir evenly;

[0062] (3) Add water-soluble salt and stir to disperse evenly;

[0063] (4) Add liquid essence, hydrophobic resin-wrapped essence, and pigment and stir for 20 minutes;

[0064] (5) Pass the mixture in the molten state in the stirring pot into the melting granulation equipment for granulation. The shape of the granulation is hemispherical and the average particle size is 0.3cm. After the granules are solidified and cooled, they are packaged.

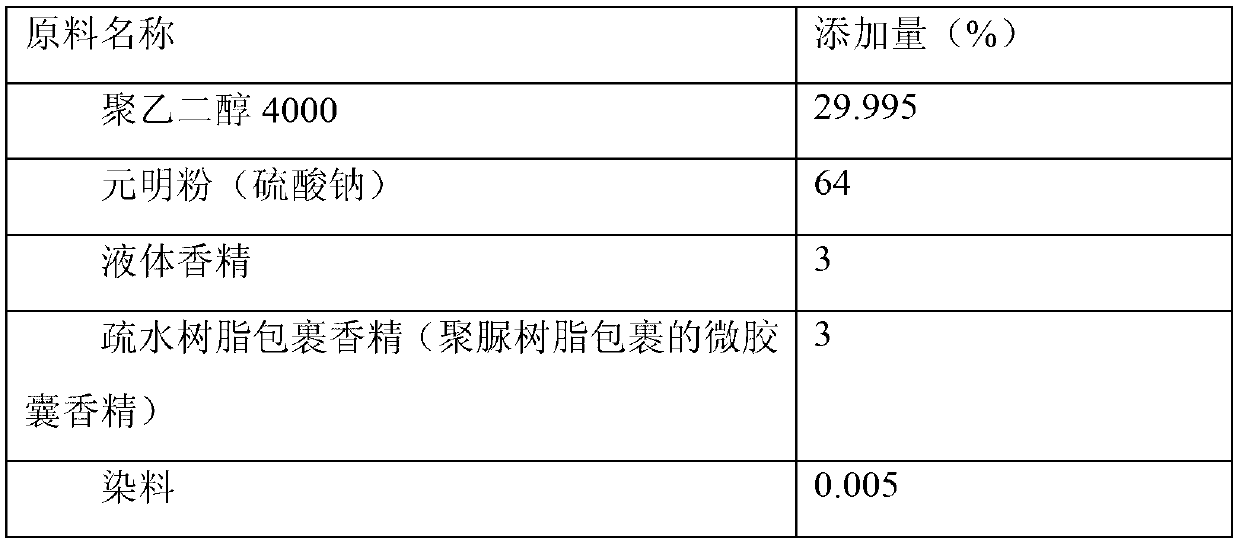

[0065] The composition of the clothing fragrance granule of table 3 embodiment 2

[0066]

Embodiment 3

[0068] What this embodiment adopts is the improved technology that uses polyethylene glycol and water-soluble salt as the carrier, and the components and contents are shown in Table 4. The preparation steps of the clothing fragrance granules are as follows:

[0069] (1) Add polyethylene glycol into a stirring pot, heat to 80°C, and stir until it becomes a transparent liquid;

[0070] (2) Add the pigment into the mixing pot and stir evenly;

[0071] (3) Add water-soluble salt and stir to disperse evenly;

[0072] (4) Add liquid essence, hydrophobic resin-wrapped essence, and pigment and stir for 20 minutes;

[0073] (5) Pass the mixture in the molten state in the stirring pot into the melting granulation equipment for granulation. The shape of the granulation is hemispherical and the average particle size is 0.3cm. After the granules are solidified and cooled, they are packaged.

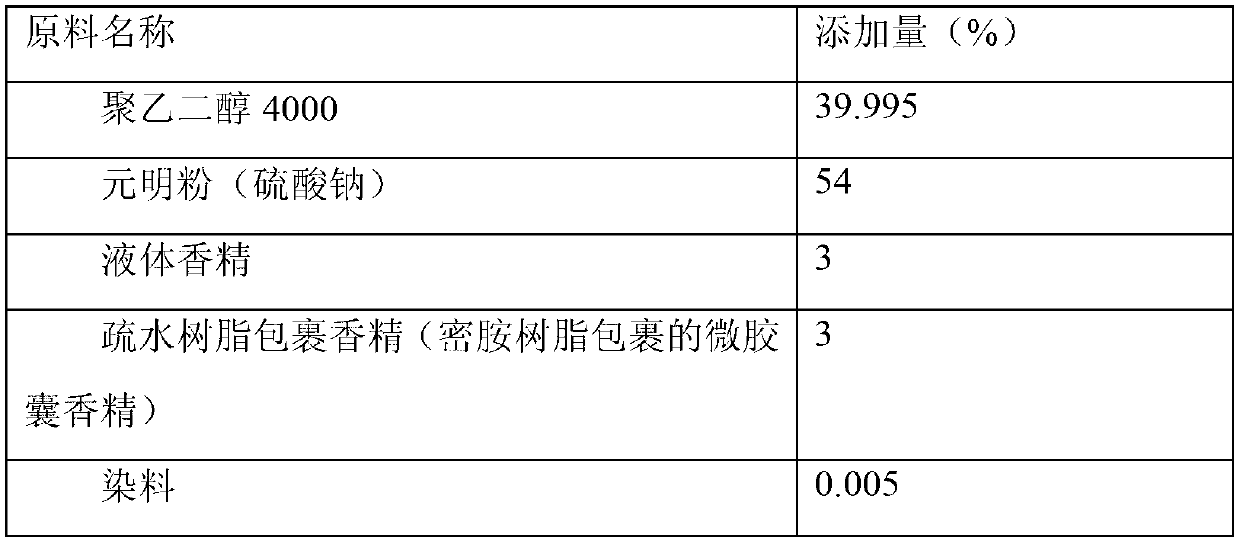

[0074] The composition of the clothing fragrance granule of table 4 embodiment 3

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com