High-efficacy environment-friendly compound feed for layer hens

A compound feed and environment-friendly technology, applied in the field of laying hen feed, can solve the problems of large nitrogen and phosphorus discharge, poor protein quality, high crude protein content, etc., reduce phosphorus discharge in chicken manure, improve health status, and improve breeding environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

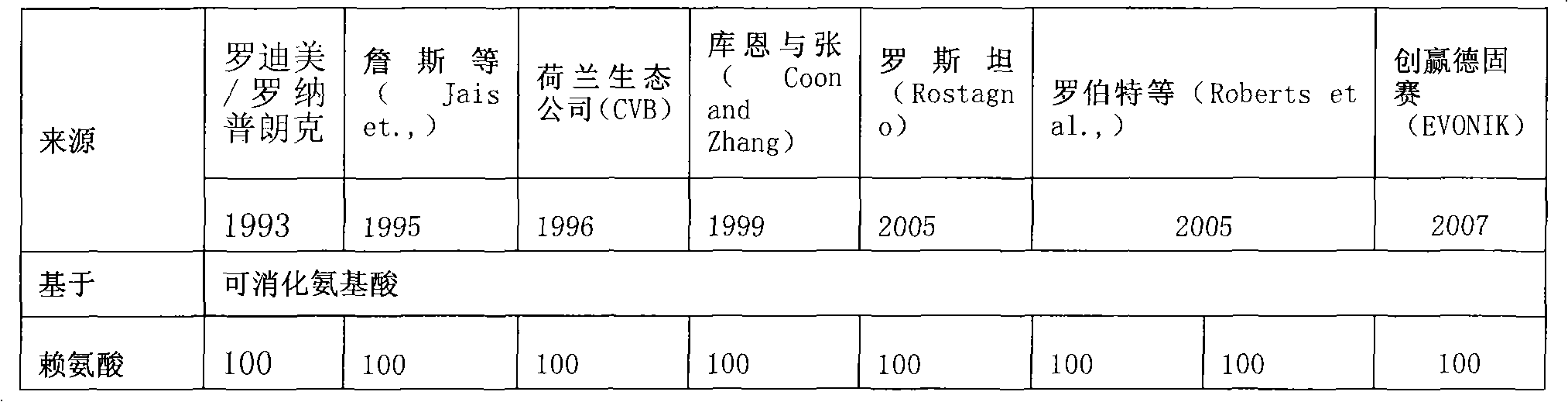

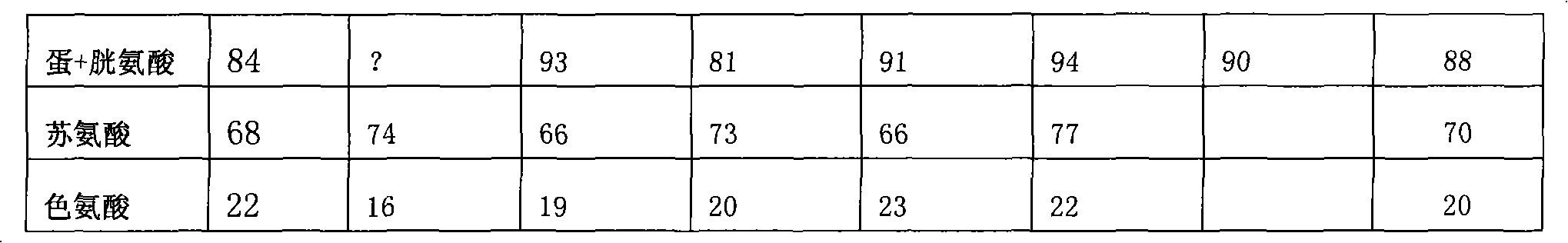

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The raw material of the present invention consists of the following components by weight: 639.85 parts of corn per 1000 parts, 120 parts of soybean meal, 83 parts of stone powder, 20 parts of DDGS, 25 parts of sunflower kernel meal, 25 parts of corn germ cake, corn gluten powder 21.8 parts, 35 parts of cottonseed meal, 10 parts of compound premix for laying hens, 4.6 parts of soybean oil, 7.8 parts of calcium hydrogen phosphate, 3 parts of table salt, 0.8 parts of choline chloride, 2.05 parts of lysine hydrochloride, methionine 1.6 parts, 0.2 parts of threonine, 0.12 parts of phytase (5000 units of enzyme activity / gram), 0.18 parts of compound enzyme for laying hens.

[0033] Among them, the compound premix for laying hens is applied according to the better selection method mentioned above. The compound premix for laying hens in all embodiments is all the same.

[0034] Compound enzymes for laying hens are applied according to the better selection methods...

Embodiment 2

[0042] Embodiment 2: The raw material of the present invention consists of the following components by weight: 640 parts of corn, 170 parts of soybean meal, 85 parts of stone powder, 21.3 parts of DDGS, 10.4 parts of corn gluten meal, 10 parts of cottonseed meal, and corn germ cake per 1000 parts 22.6 parts, 3 parts of sunflower kernel meal, 11 parts of compound premix for laying hens, 11.6 parts of soybean oil, 6.7 parts of calcium hydrogen phosphate, 3 parts of table salt, 1.2 parts of choline chloride, 1.6 parts of lysine hydrochloride, 2 parts of methionine, 0.3 parts of threonine, 0.1 parts of phytase (5000 units of enzyme activity / gram), 0.2 parts of compound enzyme for laying hens.

[0043] The digestible amino acid value in the feed of embodiment 2 is calculated as follows:

[0044] Lysine%

[0045] Preparation method: grind corn, soybean meal, DDGS, corn gluten meal, cottonseed meal, sunflower kernel meal, and corn germ cake to a woven sieve with a particle ...

Embodiment 3

[0046] Embodiment 3: The raw material of the present invention is composed of the following components by weight: 616.6 parts of corn per 1000 parts, 152.3 parts of soybean meal, 84 parts of stone powder, 45 parts of DDGS, 22.3 parts of sunflower kernel meal, 2 parts of corn germ cake, corn protein 15 parts of flour, 28 parts of cottonseed meal, 12 parts of compound premix for laying hens, 8.1 parts of soybean oil, 6.7 parts of calcium hydrogen phosphate, 2.5 parts of table salt, 1 part of choline chloride, 2 parts of lysine hydrochloride, 1.9 parts of methionine, 0.3 parts of threonine, 0.12 parts of phytase (5000 units of enzyme activity / gram), 0.18 parts of compound enzyme for laying hens.

[0047] The digestible amino acid value in the feed of embodiment 3 is calculated as follows:

[0048] Lysine%

[0049] Preparation method: grind corn, soybean meal, DDGS, corn gluten powder, sunflower kernel meal, corn germ cake, and cottonseed meal according to the weight per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com