Terpolymer block hydrophilic amino silicone oil and preparation method and application thereof

A technology of ternary copolymerization block and amino silicone oil, which is applied in the application fields of ternary copolymerization block hydrophilic amino silicone oil, ternary copolymerization block hydrophilic amino silicone oil, and chemical fiber fabric softener. The fabric is easy to yellow, wear performance is reduced, and it is stuffy to wear. It has good acid, alkali and salt chemical stability, yellowing and color change, and good softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0037] Embodiment 1 Ternary copolymer block hydrophilic amino silicone oil

[0038] A kind of ternary copolymerization block hydrophilic amino silicone oil of the present embodiment, its preparation method specifically comprises the following steps:

[0039] step 1.

[0040] Add 500g terminal hydrogen-containing silicone oil (molecular weight: 8000) and 38.63g allyl epoxy polyether (molecular weight: 300) into the reaction kettle, and raise the temperature to 110°C, react for 3h, then raise the temperature to 125°C, and vacuumize for 30min ( Vacuum degree is -0.08MPa), then the epoxy-terminated polyether silicone oil is prepared;

[0041] Mix the above-mentioned epoxy-terminated polyether silicone oil, amino-terminated polyether and isopropanol evenly, then raise the temperature to 83°C, keep the temperature for reflux reaction for 10 hours, and obtain ternary copolymerization block silicone crude oil;

[0042] Step 2.

[0043] Adding a quaternizing agent and ternary copoly...

Embodiment 2 3

[0052] Example 2 Ternary copolymer block hydrophilic amino silicone oil

[0053] A kind of ternary copolymerization block hydrophilic amino silicone oil of the present embodiment, its preparation method specifically comprises the following steps:

[0054] step 1.

[0055] Add 500g terminal hydrogen-containing silicone oil (molecular weight: 8000) and 38.63g allyl epoxy polyether (molecular weight: 300) into the reaction kettle, and raise the temperature to 110°C, react for 3h, then raise the temperature to 125°C, and vacuumize for 30min ( vacuum degree is 0.1MPa), then the epoxy-terminated polyether silicone oil is prepared;

[0056] Mix the above-mentioned epoxy-terminated polyether silicone oil, amino-terminated polyether and isopropanol evenly, then raise the temperature to 80°C, keep the temperature for reflux reaction for 10 hours, and obtain ternary copolymerization block silicone crude oil;

[0057] Step 2.

[0058] Adding a quaternizing agent and ternary copolymeriz...

Embodiment 3 3

[0064] Example 3 Ternary copolymer block hydrophilic amino silicone oil emulsion

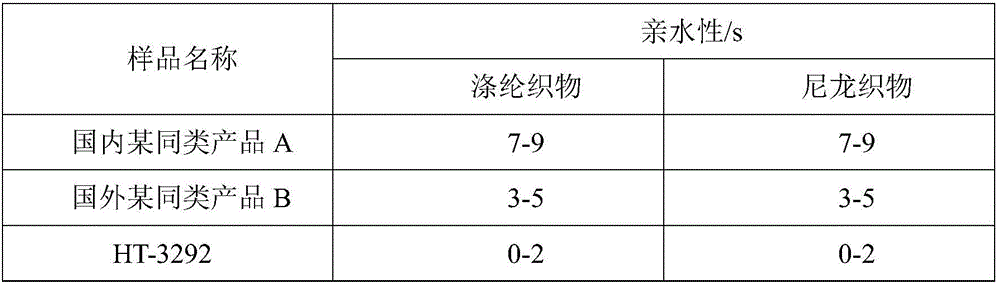

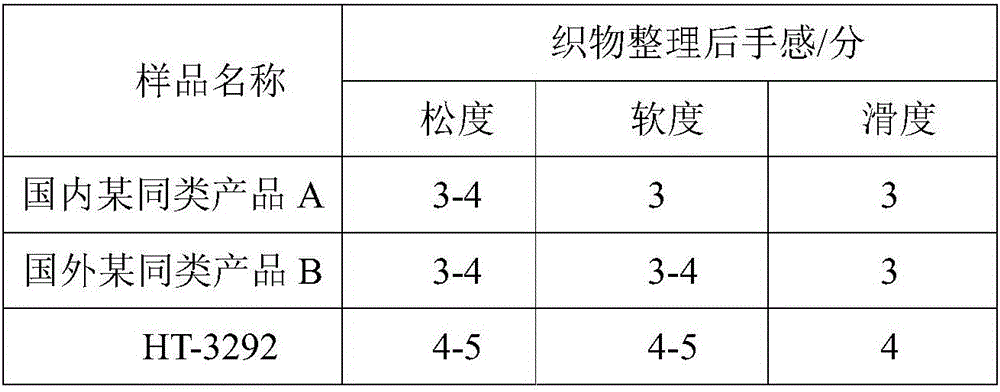

[0065] Accurately take by weighing 500 g of the ternary copolymerization block hydrophilic amino silicone oil prepared in Example 1, then add 15 g of glacial acetic acid, stir with a stirring speed of 500 rpm for 10 minutes, keep the stirring speed constant, then add 2500 g of water, After continuing to stir for 60 minutes, stop stirring and let it stand until it is completely clear to obtain a light yellow transparent microemulsion, which is the desired ternary copolymerized block hydrophilic amino silicone oil emulsion, named HT-3292.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com