A printing and dyeing process of diacetate fiber and corn fiber high elastic fabric

A technology of diacetate fiber and corn fiber, applied in the field of printing and dyeing, can solve the problems of high dyeing conditions, difficult to obtain uniform color of high-elasticity fabrics, etc., achieve super strong removal ability, good color fastness and saturation, and save water. and energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

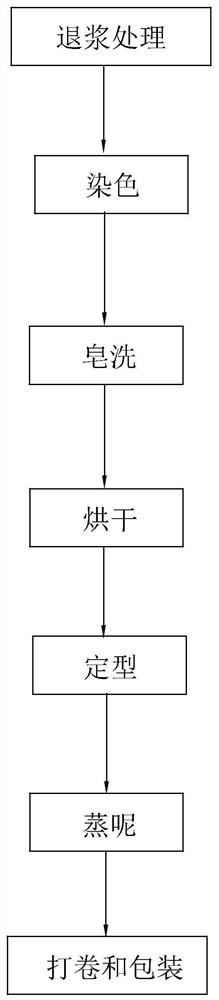

[0035] Embodiment 1: a kind of printing and dyeing process of diacetate fiber and corn fiber high elastic fabric, as figure 1 shown, including the following steps:

[0036] Step a, desizing treatment: add the gray cloth to the desizing aqueous solution composed of 2g / L, 4g / L hydrogen peroxide and 2g / L sodium dodecylbenzenesulfonate for desizing treatment, the treatment temperature is 98°C, and the treatment time is for 0.5h, and then wash with water at 55°C to remove residues on the gray cloth surface;

[0037] Step b. Dyeing: Take the fabric treated in step a, put it into the dyeing machine, add water, gradually raise the temperature of the water bath to 110°C, and add disperse dyes and 3g / L superfine fiber at a high speed when the temperature of the water bath is 70°C. Dye YC-201, keep warm at 110°C for 0.45h, disperse dye adopts disperse blue EX-SF 300% 3-3.5% (owf), superfine fiber high-speed leveling agent YC-201 comes from Hangzhou-Chao Chemical Co., Ltd.;

[0038] Ste...

Embodiment 2

[0043] Embodiment 2: A kind of printing and dyeing process of diacetate fiber and corn fiber high elastic fabric, the difference with embodiment 1 is that in step a, desizing treatment: add greige fabric into 2g / L, 4g / L hydrogen peroxide and 2g / L secondary alkyl sodium sulfonate desizing aqueous solution for desizing treatment, the treatment temperature is 98°C, the treatment time is 0.5h, and then washed at 55°C to remove the residue on the surface of the gray cloth.

Embodiment 3

[0044] Embodiment 3: a kind of printing and dyeing process of diacetate fiber and corn fiber high elastic fabric, the difference with embodiment 1 is, in step b, dyeing: take the cloth after step a processing, put into the dyeing machine, add Clear water, gradually raise the water bath temperature to 110°C, add disperse dyes and 5g / L superfine fiber high-speed leveling agent YC-201 when the water bath temperature is 70°C, keep warm at 110°C for 0.45h, and use disperse blue EX for disperse dyes -SF 300% 3-3.5% (owf), superfine fiber high-speed leveling agent YC-201 from Hangzhou-Chao Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com