Method for recycling waste acid generated in production of sulfuric acid from smelting flue gas

A technology for smelting flue gas and producing sulfuric acid, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of waste of resources, low availability of sludge, unsalable sulfuric acid, etc., to reduce costs and solve seasonal storage Problems, the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

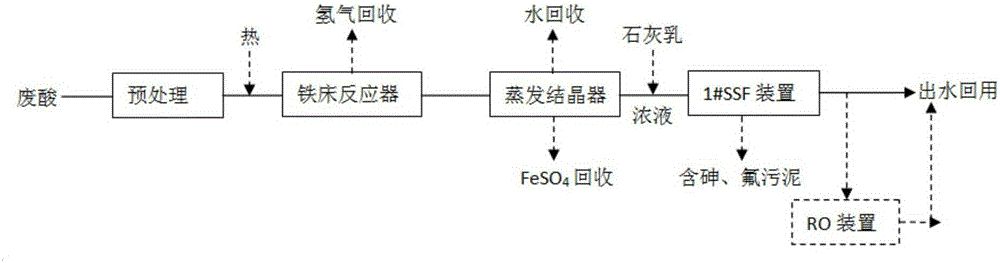

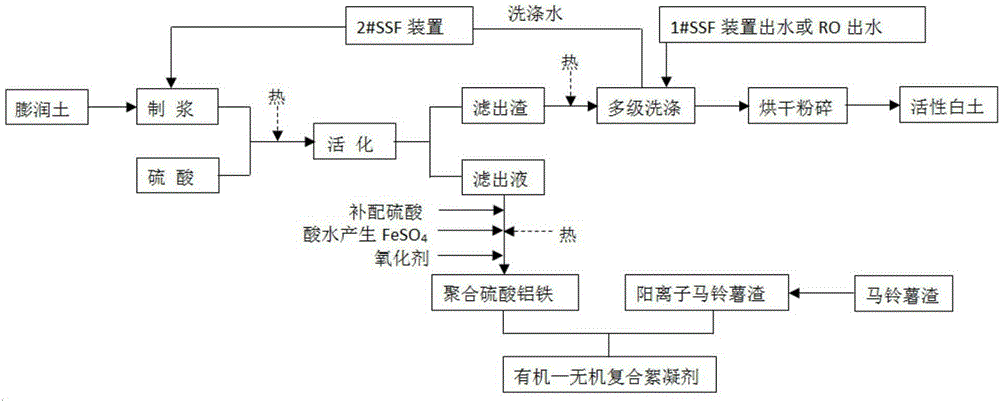

[0087] (1) Treatment of waste acid

[0088] The waste acid reduction treatment adopts the field test of the pilot plant, and no external auxiliary operation equipment is designed. The specific implementation steps are as follows:

[0089] will be 1m 3 / h of waste acid is lifted to a 10μm membrane filter, and after pretreatment of part of the suspended matter, it overflows into the iron bed reactor. The coil heating system installed in the iron bed reactor keeps the temperature of the waste acid water at 50°C. The iron filings in the iron filings reactor of the iron bed reactor is 200kg. The iron filings are completely soaked in the waste acid, and the residence time is 7 hours. During the residence time, the stirrer rotates at a speed of 80-150r / min, and the stirring speed changes from slow to fast, and from fast to slow. After the complete reaction, the pH value of the obtained waste liquid is 5.1. After the reaction is completed, the gas generated is collected through a g...

Embodiment 2

[0103] (1) Treatment of waste acid

[0104] The waste acid reduction treatment adopts the field test of the pilot plant, and no external auxiliary operation equipment is designed. The specific implementation steps are as follows:

[0105] will be 1m 3 / h of spent acid (H 2 SO 4 The mass fraction is 2%) to promote a 50 μm membrane filter, and after pretreatment of part of the suspended matter, it overflows into the iron bed reactor, and the coil heating system installed in the iron bed reactor keeps the temperature of the waste acid water at 30°C. The iron filings in the iron filings reactor of the iron bed reactor is 200kg. The iron filings are completely soaked in the waste acid, and the residence time is 7 hours. During the residence time, the stirrer rotates at a speed of 80-150r / min, and the stirring speed changes from slow to fast, and from fast to slow. After the complete reaction, the pH value of the obtained waste liquid is 5.0. After the reaction is completed, th...

Embodiment 3

[0119] (1) Treatment of waste acid

[0120] The waste acid reduction treatment adopts the field test of the pilot plant, and no external auxiliary operation equipment is designed. The specific implementation steps are as follows:

[0121] will be 1m 3 / h of spent acid (H 2 SO 4The mass fraction is 5%) to promote a 30 μm membrane filter, and after pretreatment of part of the suspended matter, it overflows into the iron bed reactor, and the coil heating system installed in the iron bed reactor keeps the temperature of the waste acid water at 60°C. The iron filings in the iron filings reactor of the iron bed reactor is 200kg. The iron filings are completely soaked in the waste acid, and the residence time is 7 hours. During the residence time, the stirrer speed is 80-150r / min, and the stirring speed changes from slow to fast, and from fast to slow. After the complete reaction, the pH value of the obtained waste liquid is 6. After the reaction is completed, the gas generated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com