Retarder and preparation method thereof

A technology for setting retarder and production wastewater, applied in the field of concrete additives, can solve the problems of limited adsorption capacity of activated carbon adsorption technology, inability to recover beneficial components, and high operating costs, achieve good retardation effect, good preheating effect, and ingenious synthesis method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

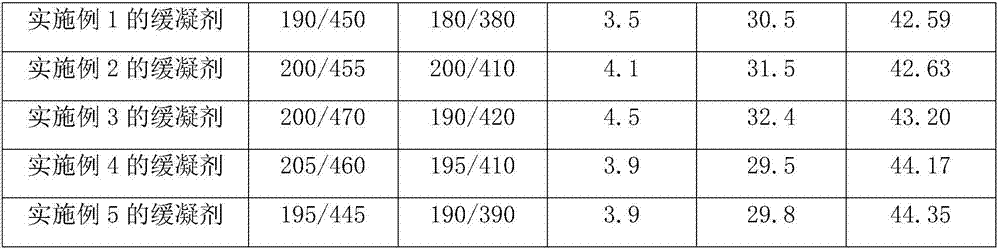

Embodiment 1

[0041] A preparation method of retarder, comprising the following steps:

[0042] Step 1: Determination of the composition content of corn starch production wastewater:

[0043] Collect 1L of cornstarch production wastewater, and measure the content of soluble cellulose, sugar, protein, starch and fatty acid in it, and the test method is carried out by conventional test methods. Calculates the mass of soluble cellulose, carbohydrates, protein, starch and fatty acids.

[0044] Step 2: Heat and concentrate:

[0045] Concentrating the cornstarch production wastewater for concentration measurement, the concentration temperature is 100° C., and the concentration time is 3-5 hours. When the mass concentration of protein in the test is 5%, the concentration is stopped to obtain the first mixed solution.

[0046] Step 3: Protein hydrolysis:

[0047] The first mixed solution after step 2 is concentrated is adjusted its pH value to 2 with sulfuric acid solution, stirs, is heated to 4...

Embodiment 2

[0053] A preparation method of retarder, comprising the following steps:

[0054] Step 1: Determination of the composition content of corn starch production wastewater:

[0055] Collect 1L of cornstarch production wastewater, and measure the content of soluble cellulose, sugar, protein, starch and fatty acid in it, and the test method is carried out by conventional test methods. Calculates the mass of soluble cellulose, carbohydrates, protein, starch and fatty acids.

[0056] Step 2: Heat and concentrate:

[0057] Concentrating the cornstarch production wastewater for concentration measurement, the concentration temperature is 120° C., and the concentration time is 3-5 hours. When the mass concentration of protein in the test is 10%, the concentration is stopped to obtain the first mixed solution.

[0058] Step 3: Protein hydrolysis:

[0059] Use hydrochloric acid solution to the first mixed solution concentrated in step 2, adjust the pH value to 3, stir, heat to 50°C, and ...

Embodiment 3

[0065] A preparation method of retarder, comprising the following steps:

[0066] Step 1: Determination of the composition content of corn starch production wastewater:

[0067] Collect 1L of cornstarch production wastewater, and measure the content of soluble cellulose, sugar, protein, starch and fatty acid in it, and the test method is carried out by conventional test methods. Calculates the mass of soluble cellulose, carbohydrates, protein, starch and fatty acids.

[0068] Step 2: Heat and concentrate:

[0069] Concentrate the cornstarch production wastewater for concentration measurement, the concentration temperature is 115° C., and the concentration time is 3-5 hours. When the mass concentration of protein in the test is 6%, the concentration is stopped to obtain the first mixed solution.

[0070] Step 3: Protein hydrolysis:

[0071] Use sulfuric acid solution to the first mixed solution concentrated in step 2, adjust the pH value to 2, stir, heat to 45°C, then add As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com