Anti-scaling treatment method for stainless steel acid waste water subsequent treatment

A treatment method, stainless steel technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as equipment scaling, and achieve the effect of eliminating scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

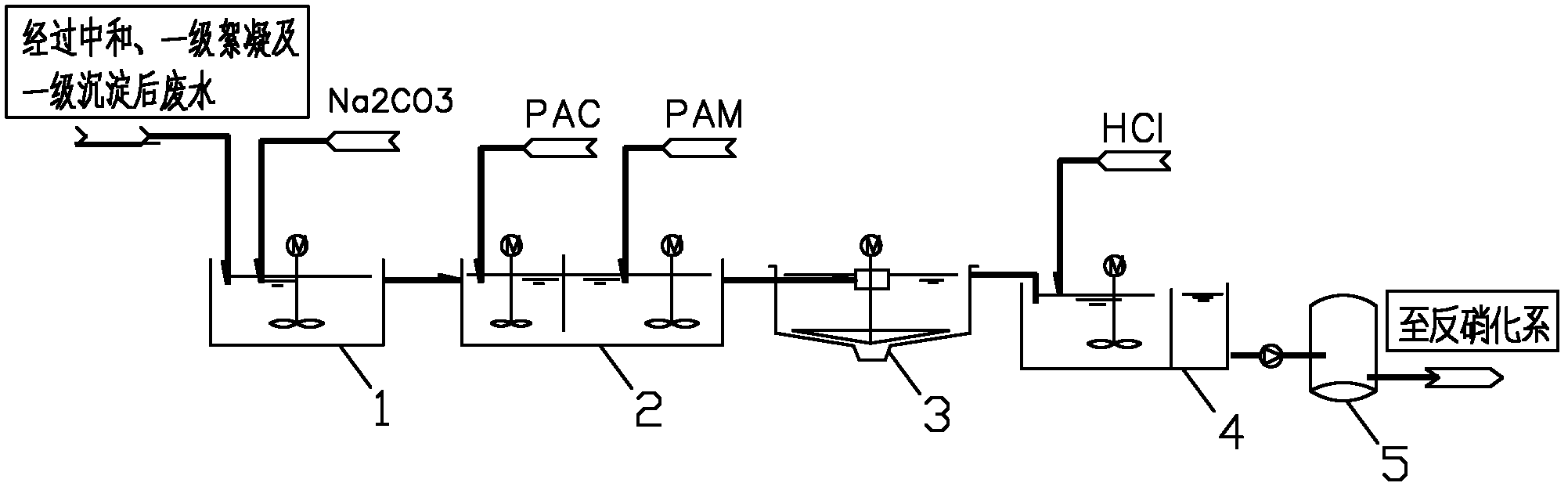

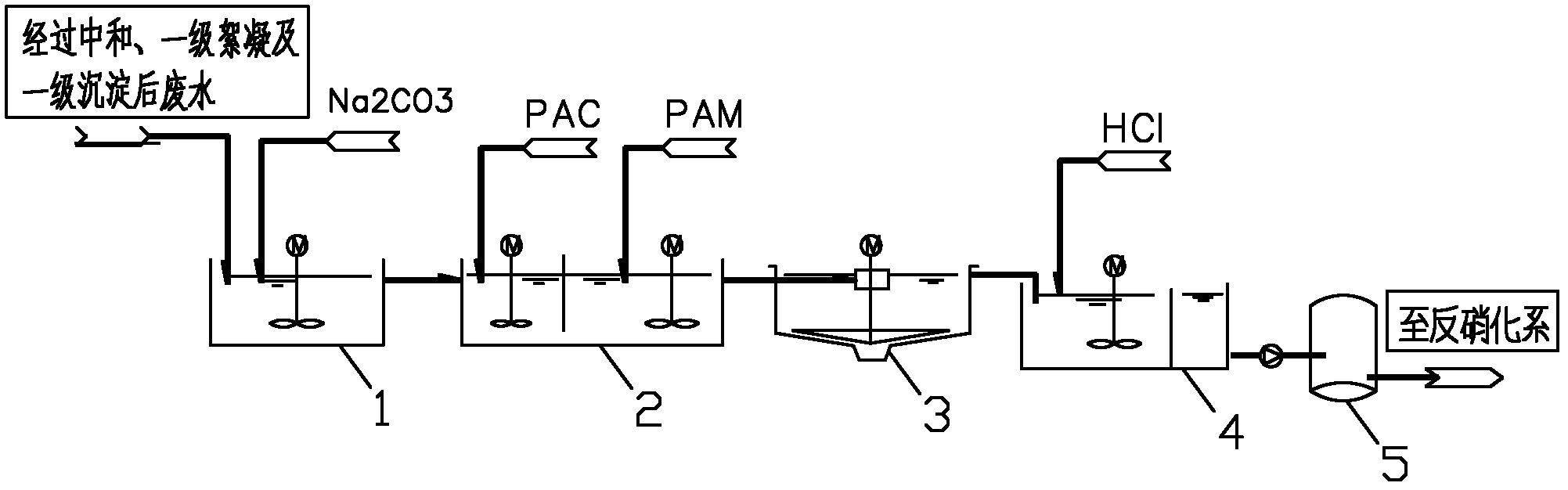

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0032] The anti-scaling treatment method for subsequent treatment of stainless steel acid wastewater provided by the invention is a method for subsequent treatment of stainless steel acid wastewater after primary reaction, primary flocculation, and primary precipitation. The method includes the following steps:

[0033] (1) Form Ca in wastewater 2+ of sediment:

[0034] The effluent after the primary precipitation enters the softening pool 1 by itself, and salt is added to the softening pool 1 to make the Ca in the secondary reaction pool 2+ Precipitation is formed, the dosage of carbonate is adjusted by frequency conversion, and the mass ratio with the calcium content in the effluent after the first-stage precipitation is 1:1;

[0035] (2) Flocculation:

[0036] The effluent softened by the softening tank 1 flows into the secondary flocculation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com