Low-cost and high-strength stainless steel and manufacturing method of welding pipe thereof

A manufacturing method and high-strength technology, which is applied in the field of high-strength stainless steel and its welded pipe manufacturing, can solve the problems of complicated adding process, increased alloy cost, and difficulty in meeting the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with embodiment.

[0081] Material preparation:

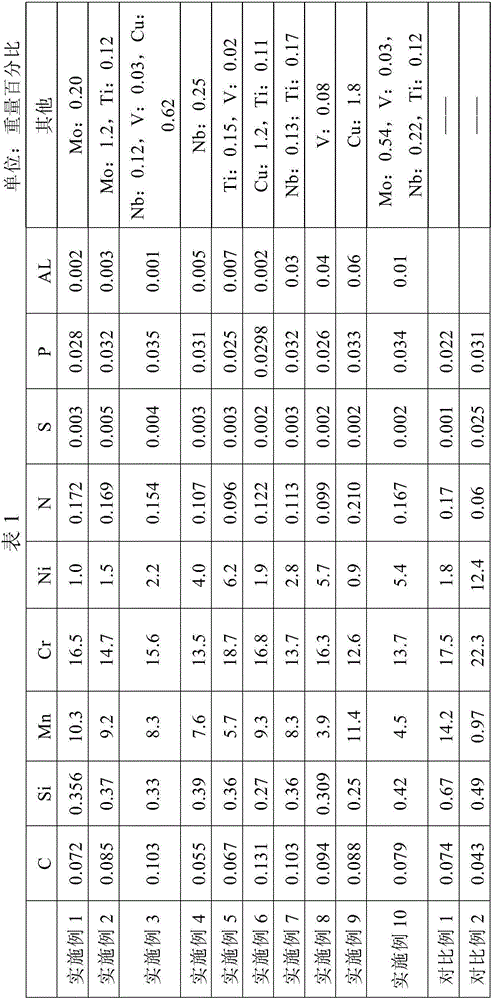

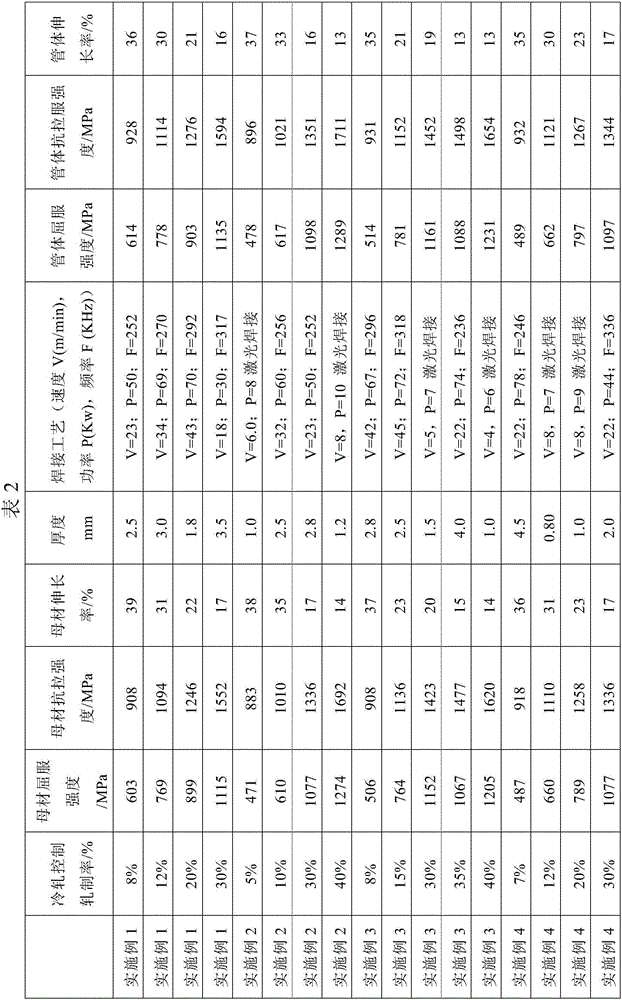

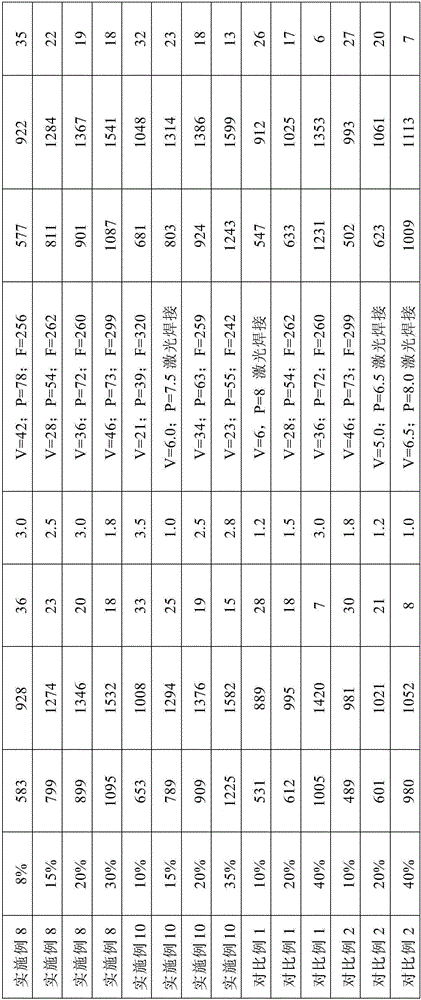

[0082] According to the chemical composition range designed above, as shown in Table 1 and Table 2, high-strength stainless steel with different strength levels can be obtained through two process routes.

[0083] According to the controlled rolling process, different contents of martensitic structures can be obtained, so as to obtain high-strength stainless steel corresponding to different strengths. According to the composition and controlled rolling, the tensile strength can be obtained from 700 to 1800MPa, the yield strength from 400 to 1200MPa, and the elongation can reach 50-12% high-strength stainless steel.

[0084] Welded pipe manufacturing:

[0085] The manufacturing examples of welded pipes are shown in Table 2, and the required welded steel pipes can be obtained.

[0086]

[0087]

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com