Method for smelting tire cord steel and method for continuously casting tire cord steel

A technology of cord steel and molten steel, applied in the field of smelting cord steel, which can solve the problems of increased content of inclusions and reduction of alloy yield, and achieve the effect of strong deformability of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This example is used to illustrate the smelting and continuous casting method of cord steel (P72LX steel).

[0072](1) Converter blowing

[0073] Add 120 tons of molten iron into the converter for top-bottom double-blowing converter blowing (top blowing oxygen 210 standard cubic meters per hour per ton of molten steel, bottom blowing protective gas with an intensity of 1.5 standard cubic meters per hour per ton of molten steel), blowing time For 20 minutes, the temperature of the molten steel at the end of blowing was 1640°C. Sampling was carried out for elemental composition analysis. The C content of the molten steel at the end of blowing was 0.08% by weight, the content of P was 0.003% by weight, and the content of S was 0.004% by weight. Content is 4×10 -4 weight%. After blowing in the converter, high magnesium lime with a magnesium oxide content of 35% by weight is added into the converter, and the dosage of the high magnesium lime is 6 kg / ton of molten steel.

...

Embodiment 2

[0084] This example is used to illustrate the smelting and continuous casting method of cord steel (P72LX steel).

[0085] Smelting cord steel and continuous casting cord steel according to the method of embodiment 1, the difference is:

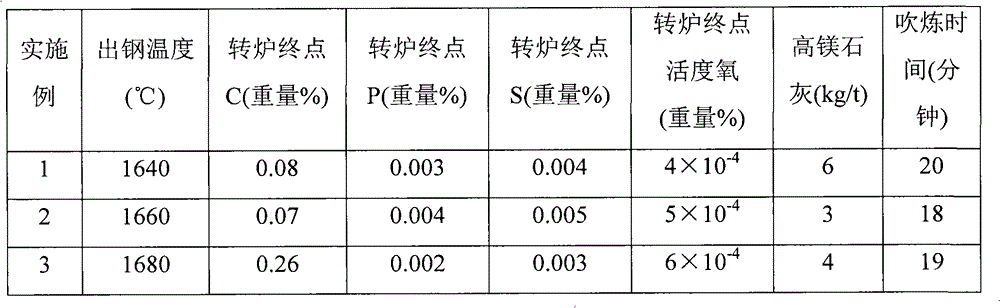

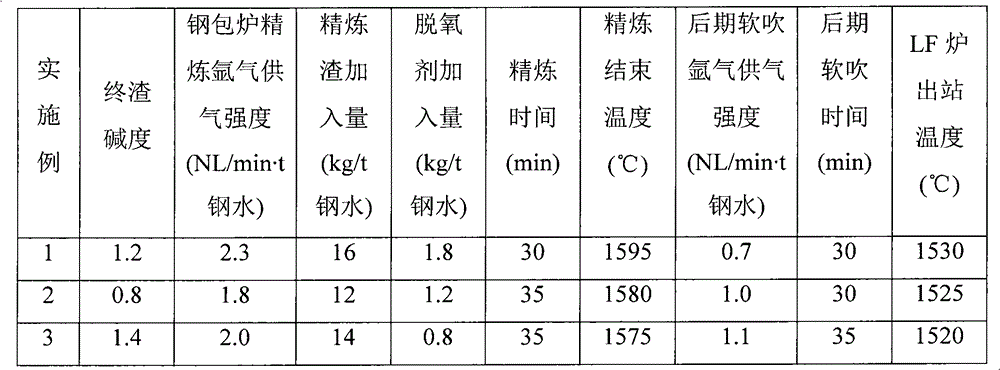

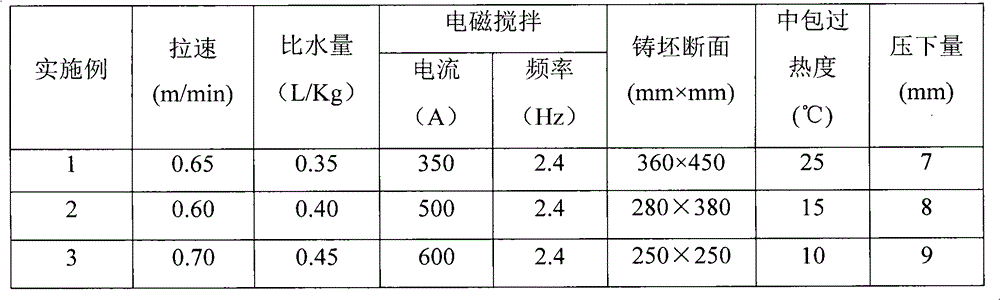

[0086] In step (1), the main technological parameters of the primary refining of the converter are as shown in Table 1;

[0087] In step (2), in the tapping process, add anthracite recarburizer according to 5 kg / ton molten steel, then add ferrosilicon alloy (silicon content is 75% by weight, balance is iron) and 4.2 kg according to 2.2 kg / ton molten steel / ton of molten steel ferromanganese alloy (manganese content is 72% by weight, and the balance is iron) is alloyed with Si and Mn. Sampling was carried out for element composition analysis. After tapping, based on the total weight of molten steel, the contents of each component were [C]: 0.65% by weight, [Si]: 0.13% by weight, [Mn]: 0.43% by weight, [Al] : 0.004% by weight, the active oxy...

Embodiment 3

[0093] This example is used to illustrate the smelting and continuous casting method of cord steel (P72LX steel).

[0094] Smelting cord steel and continuous casting cord steel according to the method of embodiment 1, the difference is:

[0095] In step (1), the main technological parameters of the primary refining of the converter are as shown in Table 1;

[0096] In step (2), in the tapping process, add anthracite recarburizer according to 8 kg / ton molten steel, then add ferrosilicon alloy (silicon content is 75% by weight, balance is iron) and 4.5 kg according to 2.3 kg / ton molten steel / ton of molten steel ferromanganese alloy (manganese content is 72% by weight, and the balance is iron) is alloyed with Si and Mn. Sampling was carried out for element composition analysis. After tapping, based on the total weight of molten steel, the contents of each component were [C]: 0.67% by weight, [Si]: 0.14% by weight, [Mn]: 0.44% by weight, [Al] : 0.003% by weight, the active oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com