Bamboo charcoal manufacturing process and its manufacturing equipment

A technology for manufacturing equipment and bamboo charcoal, which is applied in the petroleum industry, special forms of dry distillation, solid fuel, etc., can solve problems such as unstable product quality, serious pollution in the production process, and eradication of production technology and methods, and achieve thermal efficiency and comprehensive energy utilization. Improvement , reduce heat source consumption, and precisely control the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

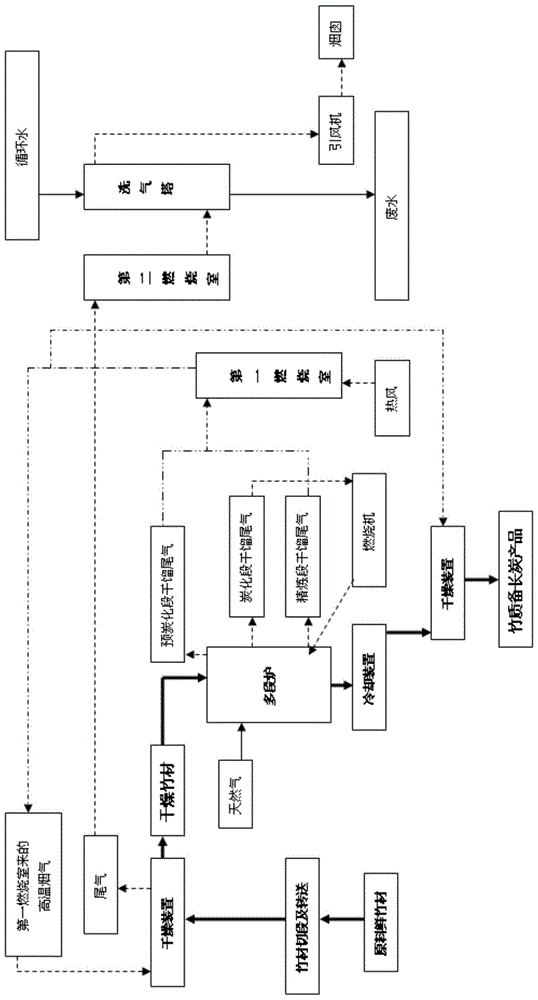

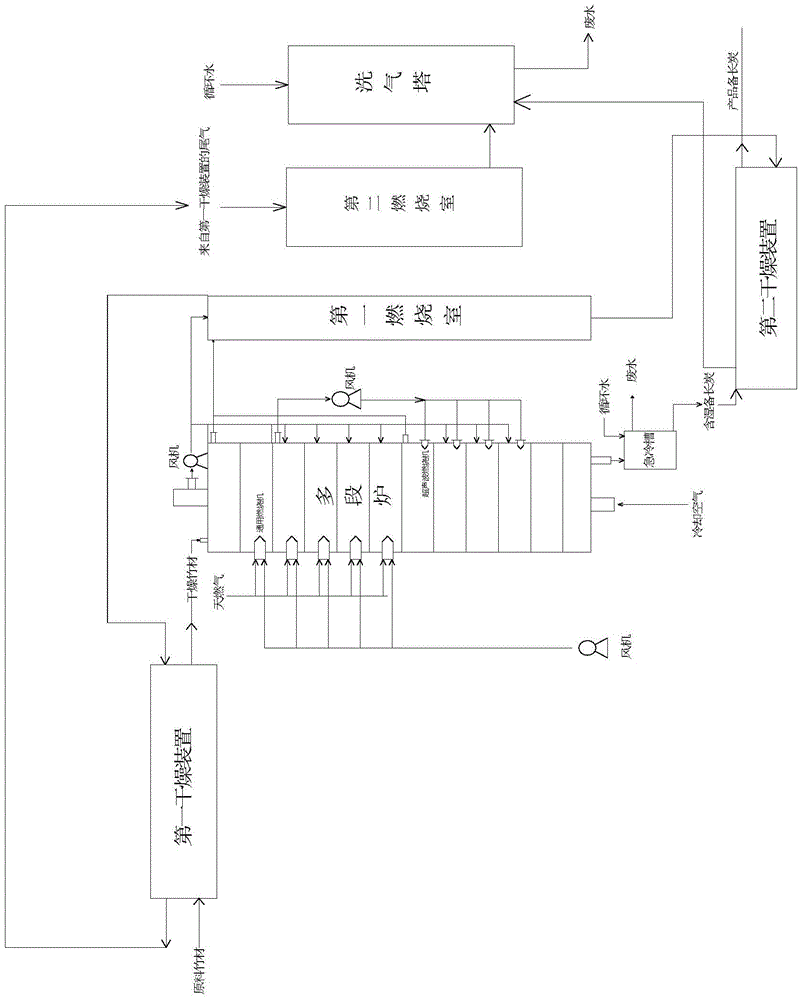

[0029] Such as Figure 1-3 Shown, the invention discloses a kind of bamboo charcoal manufacturing process, comprises the steps:

[0030] S1. Cutting into sections, cutting the bamboo into sections;

[0031] S2. Drying, the cut bamboo is sent to the dryer for drying, the tail gas generated during the drying process is transported to the afterburner, and the afterburner sends high-temperature flue gas into the dryer to dry the newly sent bamboo;

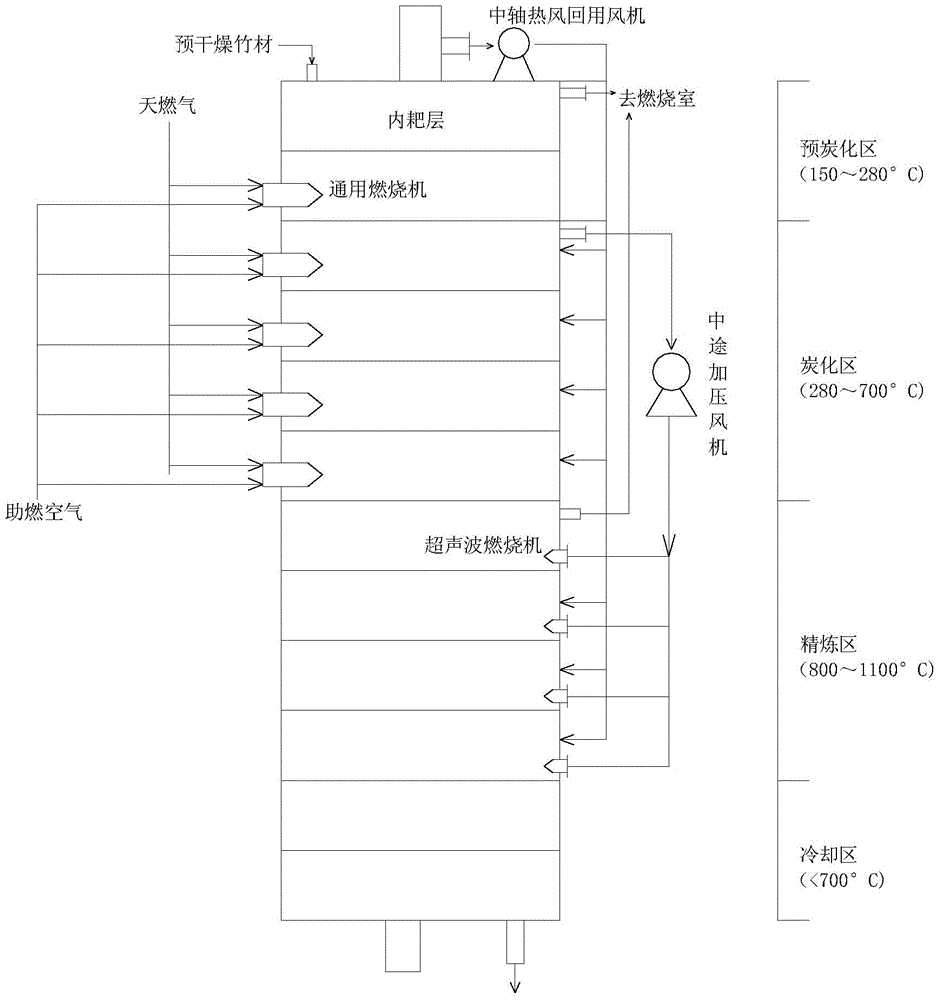

[0032] S3. Dry distillation, put the bamboo dried by the rotary kiln dryer into the multi-stage furnace for dry distillation, send the combustible gas into the multi-stage furnace to provide combustion-supporting gas for the dry distillation, and send the tail gas generated during the dry distillation into the burner or after-combustion chamber To produce high temperature flue gas;

[0033] S4. cooling, the bamboo through dry distillation is quickly sent to the water medium quenching tank for cooling;

[0034] S5. Drying again, send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com