Pre-deoxidation recarburization process for arc furnace steel-smelting molten steel with slag

A pre-deoxidation carburization and electric arc furnace technology, applied in the field of electric arc furnace steelmaking production process, can solve the problems of increased deoxidation products of molten steel, increased deoxidizer consumption, and reduced cleanliness of molten steel, etc., to reduce the generation of endogenous inclusions , Improve alloy yield, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

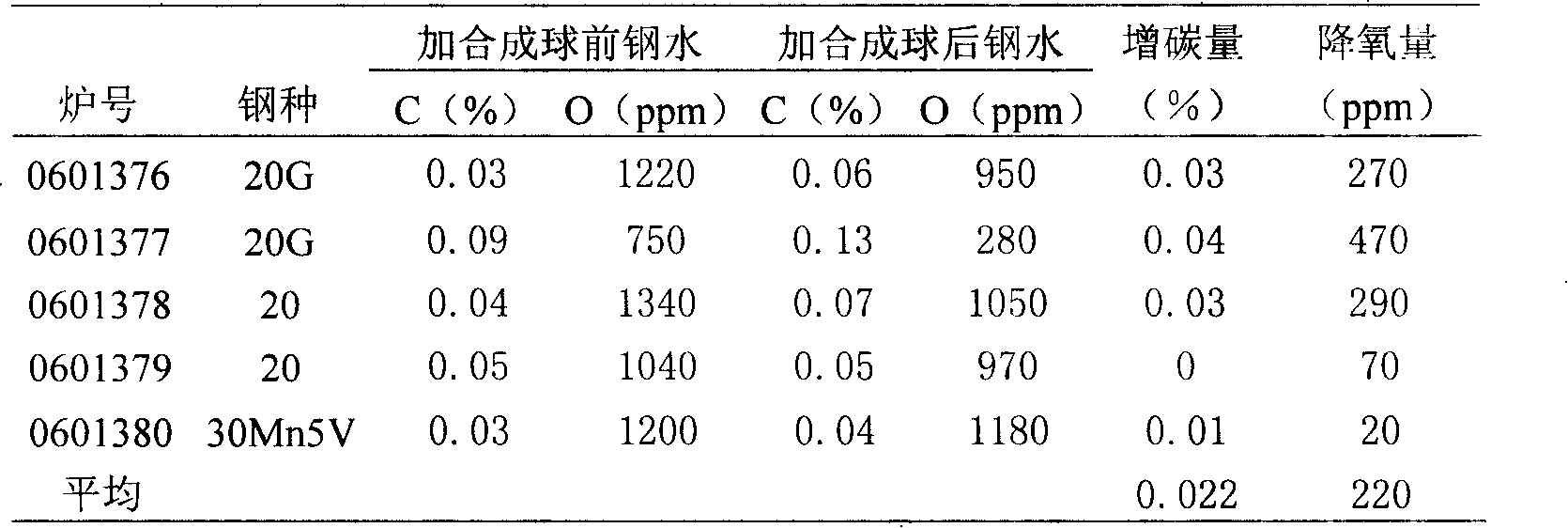

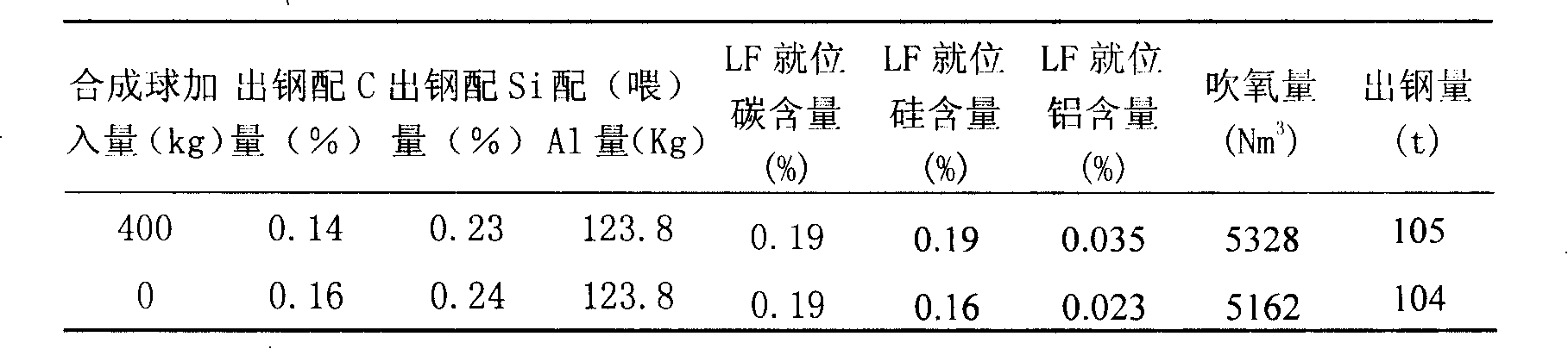

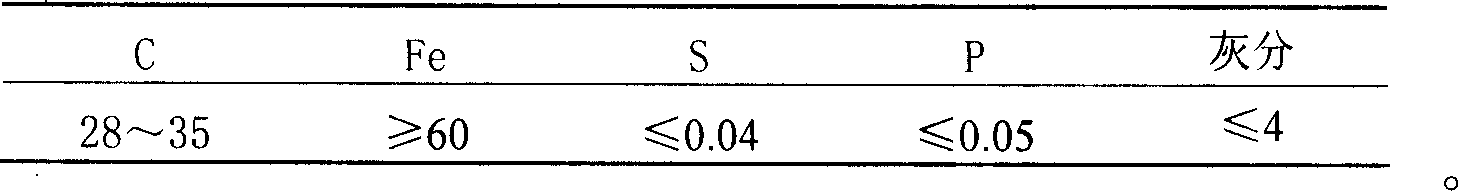

[0016] The pre-deoxidation and carburization process of molten steel with slag in the electric arc furnace steelmaking furnace of the present invention will be described in detail below in conjunction with the embodiments.

[0017] In the modern 90t ultra-high-power electric arc furnace steelmaking process using scrap steel, molten iron and other steel materials as raw materials, the furnace wall oxygen lance and furnace door oxygen lance manipulator are used to blow oxygen into the furnace for primary oxidation to remove carbon in the steel , phosphorus and other elements. After the electric arc furnace is charged, it is smelted with electricity, and at the same time, lime and dolomite slagging materials are continuously added to dephosphorize the molten steel; when the steelmaking in the electric arc furnace is completed, and the composition and temperature of the molten steel in the furnace meet the tapping conditions, the power supply is stopped at this time and oxygen blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com