Method for dynamically controlling steelmaking process of bottom blowing O2-CO2-CaO converter

An o2-co2-cao, converter steelmaking technology, applied in steel manufacturing process, manufacturing converter, sustainable manufacturing/processing, etc. problems, to avoid overoxidation, promote the balance of metallurgical reactions, and improve the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

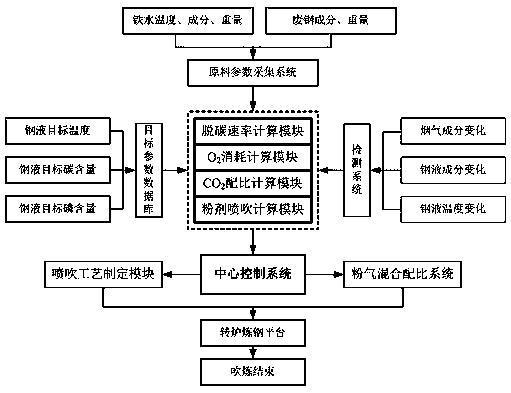

Image

Examples

Embodiment 1

[0026] 3. Embodiment 1: the present invention is applied to blow O at the bottom of 120t 2 -CO 2 -CaO converter steelmaking process, the top blowing gas is O 2 , the bottom-blown central gas includes O 2 +CO 2 , the protective gas for the bottom blown ring seam is CH 4 . Specific steps are as follows:

[0027] 1): The temperature of molten iron collected through the raw material parameter acquisition system is 1300°C, and the carbon content of molten iron is [%C] 0 =4.0%, silicon content [%Si] 0 =0.60%, phosphorus content is [%P] 0 =0.109%, the scrap carbon content is [%C] 0 =0.10%, silicon content [%Si] 0 =0.25%, phosphorus content is [%P] 0 =0.020%, the steel scrap ratio is 15%, the target carbon content is 0.02%, and the target temperature is 1635°C, which is transmitted to the blowing parameter calculation module, and the operation process in the early stage of blowing is formulated through the central control system.

[0028] 2): In the early stage of blowing, ...

Embodiment 2

[0032] Embodiment 2: The present invention is applied to blowing O at the bottom of 300t 2 -CO 2 -CaO converter steelmaking process, the top blowing gas is O 2 , the bottom-blown central gas includes O 2 +CO 2 , the protective gas for the bottom blown ring seam is CH 4 . Specific steps are as follows:

[0033] 1): The temperature of molten iron collected through the raw material parameter acquisition system is 1300°C, and the carbon content of molten iron is [%C] 0 =4.0%, silicon content [%Si] 0 =0.50%, phosphorus content is [%P] 0 =0.100%, the scrap carbon content is [%C] 0 =0.15%, silicon content [%Si] 0 =0.20%, phosphorus content is [%P] 0 =0.020%, the steel scrap ratio is 15%, the target carbon content is 0.02%, and the target temperature is 1635°C, which is transmitted to the blowing parameter calculation module, and the operation process in the early stage of blowing is formulated through the central control system.

[0034] 2): In the early stage of blowing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com