A kind of 500mpa level large-scale straight bar rebar and its preparation method

A straight rebar, large-scale technology, used in manufacturing tools, temperature control, heat treatment equipment, etc., can solve the problems of reducing the strength and bending properties of the finished product, not tempering martensite, and high temperature of the rebar cooling bed. Achieve the effect of simplifying the production process, eliminating the reticulated ferrite, and improving the product strength-to-yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

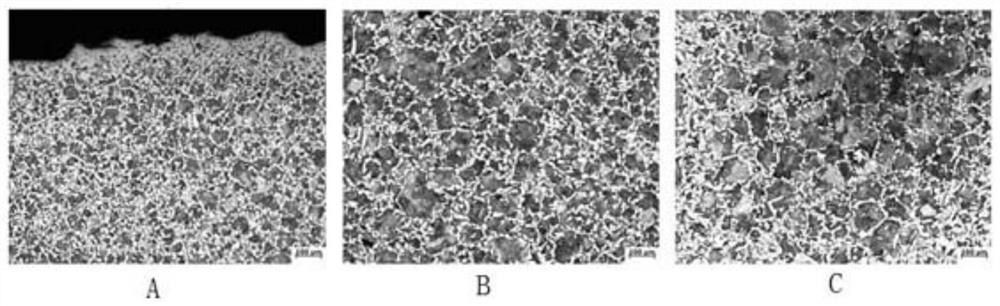

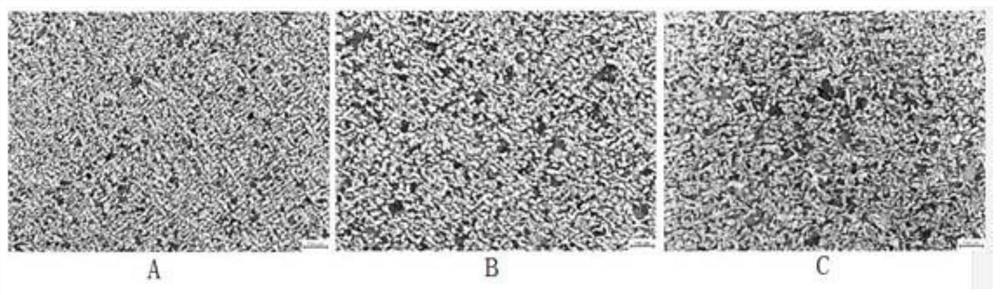

Image

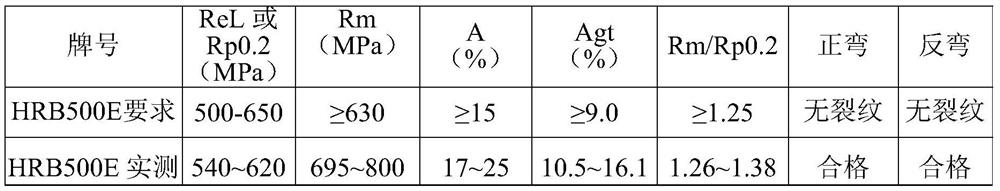

Examples

Embodiment 1

[0014] use Specification HRB500E straight rebar, the chemical composition range of the designed straight rebar billet is: C: 0.22~0.25%, Si: 0.42~0.59%, Mn: 1.38~1.57%, P: 0.015~0.045%, S : 0.008-0.045%, V: 0.100-0.115%, N: 0.010%-0.020%, and the rest are Fe and unavoidable impurities.

[0015] The specific processing steps are as follows: 100t converter→argon blowing and stirring→full protection continuous casting production (150mm×150mm billet continuous casting machine)→slab cooling→slab inspection→heating→scaling descaling→rolling→finished product inspection→packaging →Identification→Storage.

[0016] According to the designed chemical composition, the method of BOF+argon blowing and stirring is used for smelting, and the actual control of the end point: T is 1630°C, the content of P is 0.021%, and the content of S is 0.015. Tapping with red envelopes and slag blocking, the tapping time is 212s. The steel is tapped to 1 / 3, and 2865kg of deoxidizer and alloy are added a...

Embodiment 2

[0021] use Specification HRB500 straight rebar, the chemical composition range of the designed straight rebar billet is: C: 0.22~0.25%, Si: 0.42~0.59%, Mn: 1.38~1.57%, P: 0.015~0.045%, S : 0.008-0.045%, V: 0.100-0.115%, N: 0.010%-0.020%, and the rest are Fe and unavoidable impurities.

[0022] The specific processing steps are as follows: 100t converter→argon blowing and stirring→full protection continuous casting production (150mm×150mm billet continuous casting machine)→slab cooling→slab inspection→heating→scaling descaling→rolling→finished product inspection→packaging →Identification→Storage.

[0023]According to the designed chemical composition, the method of BOF+argon blowing and stirring is adopted for smelting, and the actual control of the end point: T is 1670°C, the content of P is 0.025%, and the content of S is 0.012%. Tapping with red envelopes and slag blocking, the tapping time is 255s. The steel is tapped to 1 / 3, and 2950kg of deoxidizer and alloy are added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com