Spheroidal graphite ausferrite cast iron grinding ball suitable for being used in semi-automatic grinding machine and preparation process

A technology of ductile iron grinding balls and semi-autogenous mills, which is applied in the direction of grain processing, etc. It can solve the problems of low impact value, austeric ductile iron grinding balls cannot be used in semi-autogenous mills, complex heat treatment process, etc., and achieve hardening ability Strong, high toughness, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

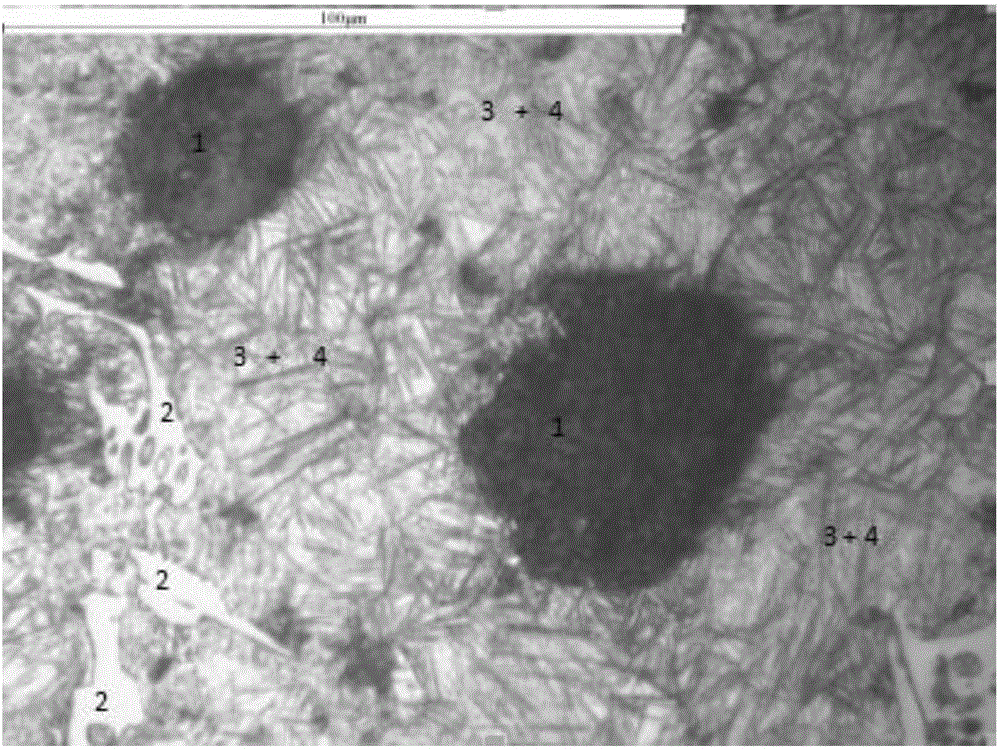

Image

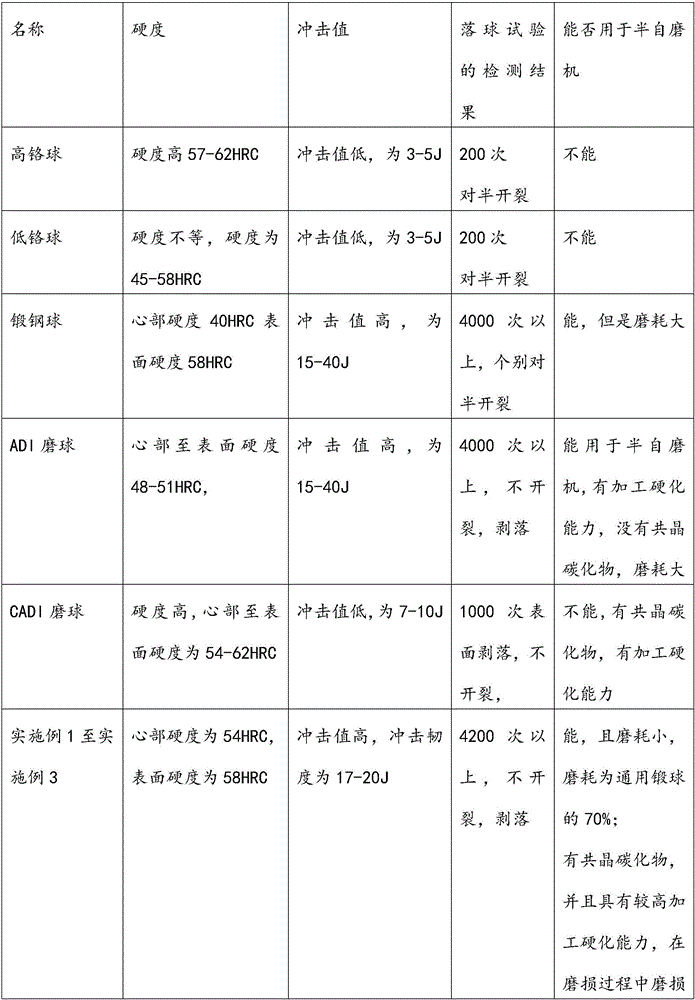

Examples

Embodiment 1

[0050] A processing technology for ausferic ductile iron grinding balls suitable for semi-autogenous mills, including the following processes:

[0051] 1) Casting molding:

[0052] The smelted molten iron is spheroidized in the molten iron ladle using a spheroidizing agent. The temperature of the smelted molten iron is 1500°C, and the spheroidization temperature of the molten iron is 1470°C. The pouring machine pours automatically, and the pouring is completed within 10 minutes, and the pouring temperature is 1380°C. Iron mold sand-covered molding process. After molding, remove the sprue to make cast grinding balls.

[0053] The smelted molten iron includes the following components in mass percentage: 3.2% carbon, 2.30% silicon, 0.96% manganese, 0.21% chromium, 0.11% copper, 0.10% molybdenum, 0.10% vanadium, 0.10% titanium, 0.01% niobium, and the balance for iron.

[0054] The addition amount of the nodulizer is 1% of the mass of molten iron; the nodulizer contains 3% magn...

Embodiment 2

[0058] A processing technology for ausferic ductile iron grinding balls suitable for semi-autogenous mills, including the following processes:

[0059] 1) Casting molding:

[0060] The smelted molten iron is spheroidized in the molten iron ladle using a spheroidizing agent. The temperature of the smelted molten iron is 1560°C, and the molten iron is spheroidized in the ladle. The pouring machine pours automatically, and the pouring is completed within 10 minutes, and the pouring temperature is 1420°C. Iron mold sand-covered molding process. After molding, remove the sprue to make cast grinding balls.

[0061] The smelted molten iron includes the following components in mass percentage: 3.9% carbon, 2.93% silicon, 2.80% manganese, 0.90% chromium, 0.60% copper, 0.80% molybdenum, 0.68% vanadium, 0.78% titanium, 0.09% niobium, and 0.045% phosphorus %, sulfur 0.023%, and the balance is iron.

[0062] The addition amount of the nodulizer is 1% of the mass of molten iron; the mas...

Embodiment 3

[0066] A processing technology for ausferic ductile iron grinding balls suitable for semi-autogenous mills, including the following processes:

[0067] 1) Casting molding:

[0068] The smelted molten iron is spheroidized in the molten iron ladle using a spheroidizing agent. The temperature of the smelted molten iron is 1530°C, and the molten iron is spheroidized in the ladle with a spheroidizing temperature of 1450°C. The pouring machine pours automatically, and the pouring is completed within 10 minutes, and the pouring temperature is 1400°C. Iron mold sand-covered molding process. After molding, remove the sprue to make cast grinding balls.

[0069] The smelted molten iron includes the following components in mass percentage: 3.50% carbon, 2.53% silicon, 1.96% manganese, 0.51% chromium, 0.31% copper, 0.40% molybdenum, 0.48% vanadium, 0.48% titanium, 0.05% niobium, and 0.02% phosphorus , sulfur 0.02%, the balance is iron.

[0070] The added amount of the nodulizer is 1% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com