Low carbon 520MPa grade composite fortified ultra fine crystal grain band steel

A technology of ultra-fine grain and strip steel, which is applied in the field of preparation of low-carbon high-strength steel, can solve the problems of super-SS400 steel such as low tensile strength, poor formability, and large gap, so as to improve performance, promote replacement, The effect of reducing the cost of steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

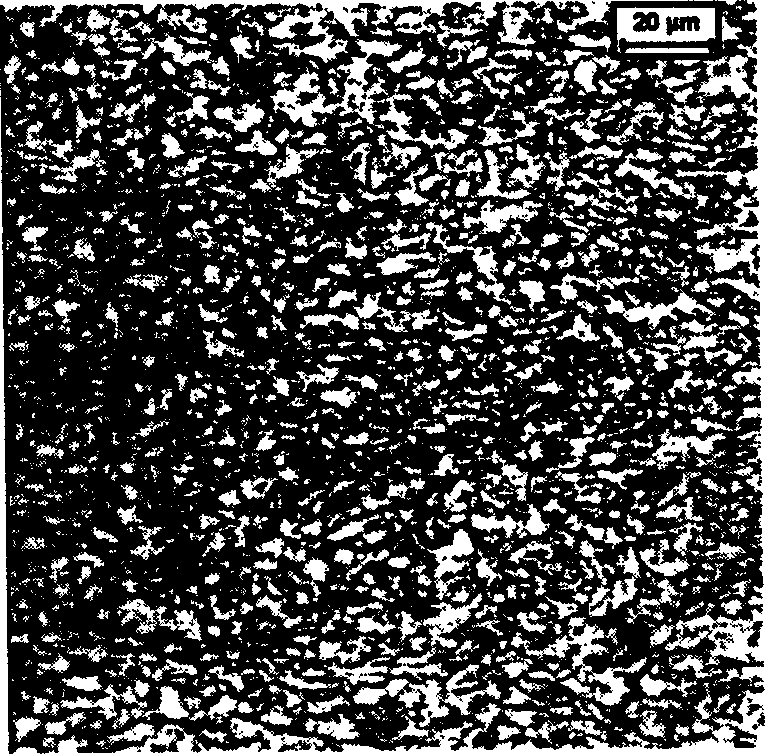

[0017] According to the chemical composition range set by the ultra-fine-grained strip steel of the present invention, two groups are selected, numbered as A, B, and C, which are respectively smelted on a 200-ton converter, and continuously cast into a continuous casting slab of 250mm × 1300mm × 10020mm, at 2050 Rolled on a hot rolling mill. The selected chemical components are listed in Table 1, the TMCP process conditions are listed in Table 2, the corresponding mechanical properties are listed in Table 3, and the metallographic structure test results are listed in Table 4. The metallographic structure is shown in Figure 1.

[0018] The chemical composition (weight, %) of table 1 embodiment ultra-fine grain strip steel

[0019] Code C Si Mn Nb S S Fe

[0020] A 0.13 0.20 1.25 0.007 0.009 0.01 Margin

[0021] B 0.12 0.35 1.10 0.009 0.008 0.009 Margin

[0022] C 0.15 0.40 1.30 0.013 0.007 0.006 Margin

[0023] Table 2 TMCP process system

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com