Rare earth modified high oxygen titanium powder for 3D printing and preparation method

A 3D printing and rare earth modification technology, applied in the field of 3D printing materials, can solve the problems of restricting the promotion and use of 3D printing titanium products, poor fluidity, low plasticity of printing materials, etc. Excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: prepare Y-containing titanium powder with hydrodehydrogenation titanium powder

[0037] The hydrogenated dehydrogenation titanium powder (all particle size2 The powder was mechanically mixed for 12 hours under the protection of Ar to obtain a mixed powder; the mixed powder was taken out and put into a cold isostatic pressing bag for pressing at a pressure of 150 MPa and held for 5 minutes. The pressed blank is put into a vacuum furnace and sintered into a rod, and the vacuum degree during sintering is -3 Pa, the sintering temperature is 1200°C, and the sintering time is 1.5h. After the sintered bar is processed, the electrode induction melting gas atomization method is used for atomization and powder production.

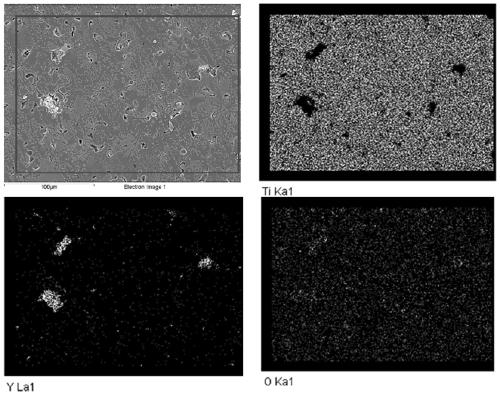

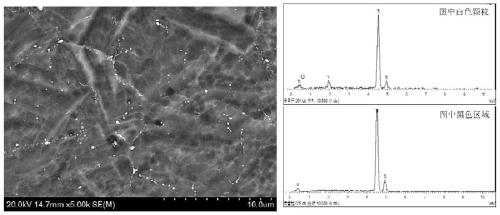

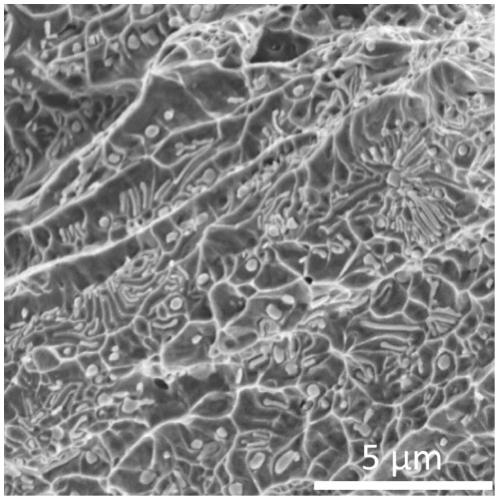

[0038] figure 1 It is the distribution of main elements in the sintered rod, and the white particles in the figure are Y 2 o 3 The particles, whose size is about 20 μm, are unevenly distributed throughout the cross-section. The composition of...

Embodiment 2

[0041] Embodiment 2: with TiH 2 Powder preparation of Ce-containing titanium powder

[0042] TiH 2 powder (2 The powder was mechanically mixed for 12 hours under the protection of Ar to obtain a mixed powder; the mixed powder was taken out and put into a mold for compression molding at a pressure of 250 MPa and held for 5 minutes. The pressed blank is put into a vacuum furnace for sintering, and the vacuum degree during sintering is -3 Pa, the sintering temperature is 1200°C, and the sintering time is 2h.

[0043] The sintered blank is atomized and powdered by electrode induction melting gas atomization method after turning. The oxygen content of the atomized powder is 0.35wt.%, and the Ce content is 0.28wt.%. The powder with a particle size in the range of 53-120 μm was screened out as the raw material for laser coaxial 3D printing. After 3D printing, the tensile strength of the material is 650MPa, and the elongation is 25%.

Embodiment 3

[0044] Embodiment 3: manufacture Y-containing titanium powder with titanium powder

[0045] Titanium scrap powder (2 The powder was mechanically mixed for 12 hours under the protection of Ar to obtain the mixed powder; the mixed powder was taken out and placed in a circular steel sheath for degassing treatment, the degassing temperature was 500 °C, and the vacuum degree was -3 Pa, degassing holding time 3h. The material after wrapping and degassing treatment is placed in a hot isostatic pressing furnace for densification at a temperature of 900°C and a pressure of 150 MPa for 3 hours.

[0046] After the obtained rods are machined, the electrode induction melting gas atomization method is used for atomization and pulverization. The oxygen content of the powder after atomization is 0.63wt.%, and the Y content is 0.55wt.%. The powder with a particle size in the range of 53-120 μm was screened out as the raw material for laser coaxial 3D printing. After 3D printing, the tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com