High-strength high-toughness low temperature steel for ship and manufacture method thereof

A manufacturing method and high-toughness technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems that affect the comprehensive performance of the ship plate, cannot be completely eliminated, and lamellar tearing, etc., to promote the formation of multi-phase structure and refinement, promoting the denaturation of inclusions, and the full effect of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

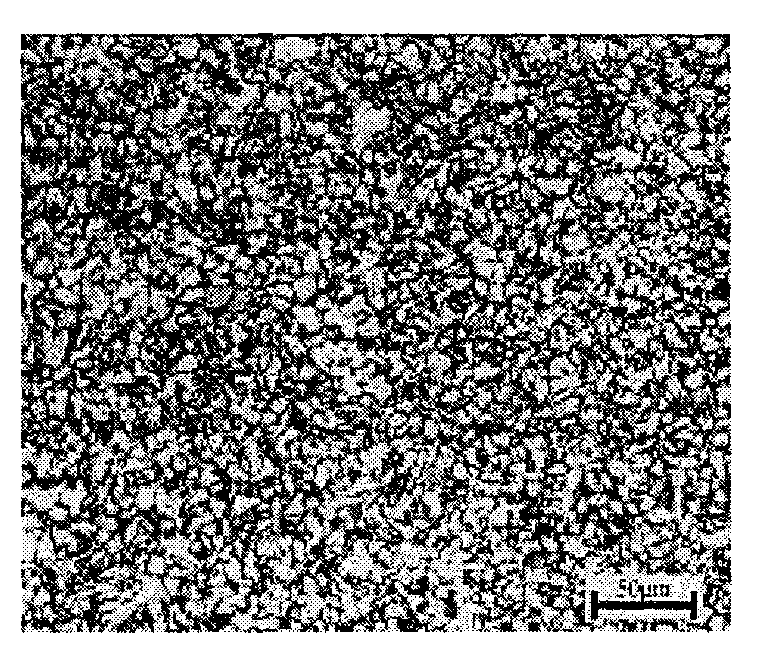

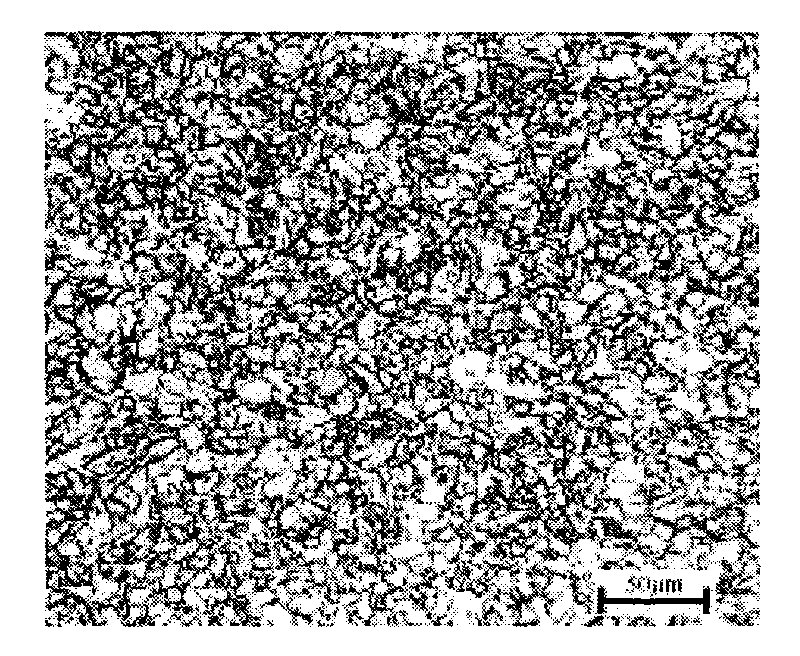

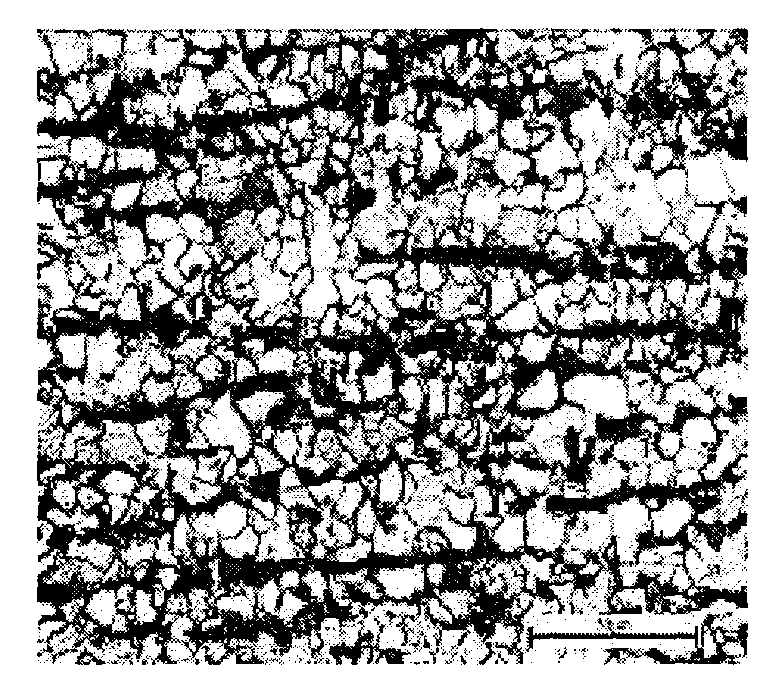

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments:

[0033] The production process route of the high-strength and high-toughness marine low-temperature steel of the present invention is as follows:

[0034] Deep desulfurization of molten iron-converter smelting-refining outside the furnace (alloying or feeding silicon-calcium wire)-continuous casting of medium and thin slabs-heating-rough rolling-finishing rolling-laminar cooling-finished product off-line.

[0035] The chemical composition of the steel of the present invention and the traditional EH36 two comparative steels is shown in Table 1.

[0036] Table 1 Chemical composition of invention steel and comparative steel (wt%)

[0037]

[0038] The cast slabs with the above composition are rolled in two stages. The invention steels 1, 2, and 3 adopt low temperature heating + controlled rolling, and the comparative steels 1 and 2 adopt conventional hot rolling. The preparation process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com