Multiple ingot vacuum running castings device and method for vacuum running castings using same

A vacuum casting and vacuum technology, which is applied to equipment, manufacturing tools, and foundry workshops for feeding molten metal into molds. Pouring quality, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

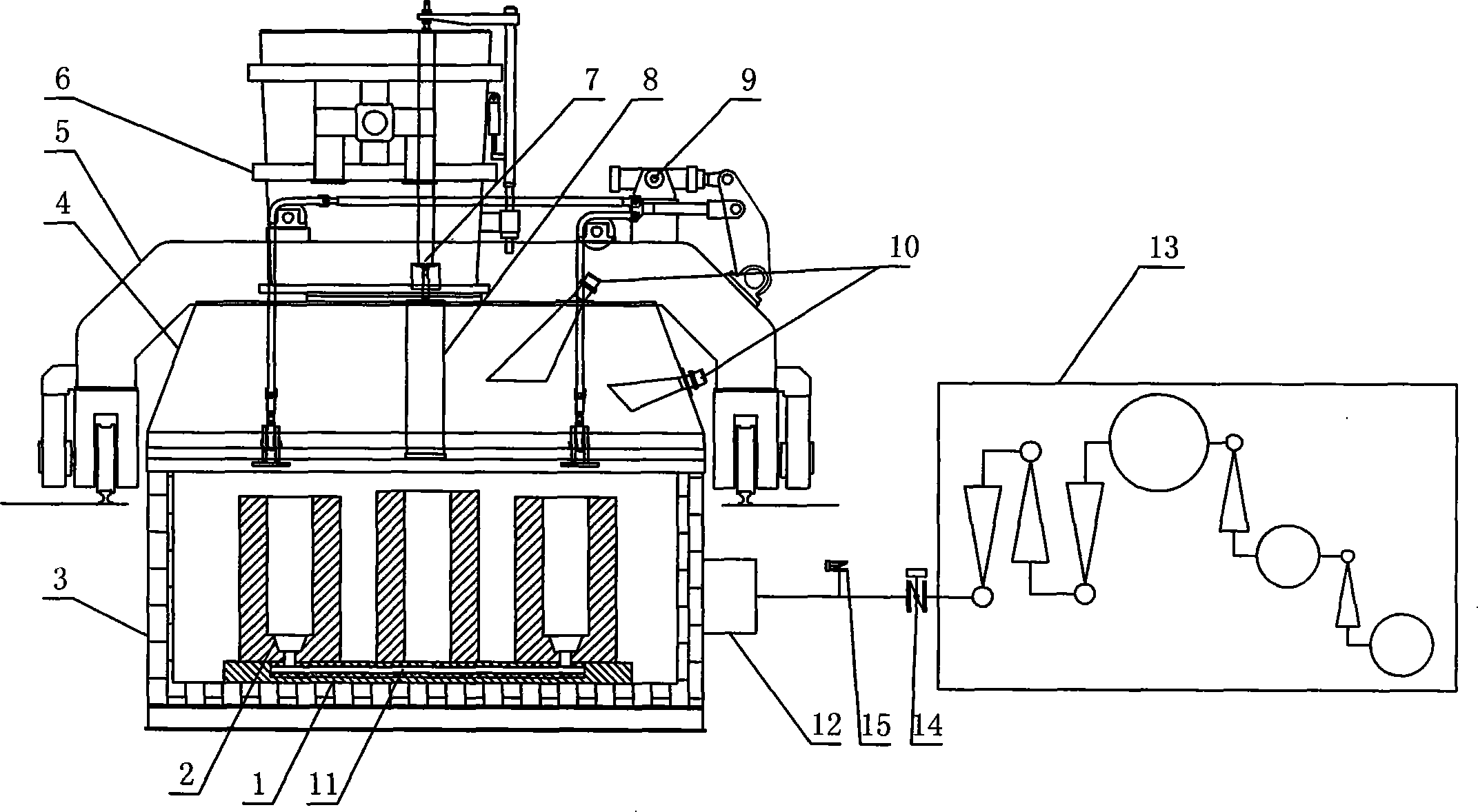

[0022] see figure 1 , The vacuum multi-ingot pouring device of the embodiment of the present invention includes: chassis 1, steel ingot mold 2, vacuum tank 3, vacuum cover 4, vacuum cover car 5, tundish 6, sliding nozzle mechanism 7, diversion sleeve 8, lifting mechanism 9 , observation window 10, shunt pipe 11, exhaust pipe 12, five-stage vacuum pump system 13, main vacuum valve 14, vent valve 15, chassis 1 is installed in vacuum tank 3, shunt pipe 11 is installed on chassis 1, on chassis 1 The steel ingot mold 2 is installed, the vacuum cover 4 is connected with the lifting mechanism 9 installed on the vacuum cover car 5, the vacuum tank 3, the vacuum cover 4, the tundish 6, and the sliding nozzle mechanism 7 form a closed vacuum chamber, and the sliding nozzle mechanism 7 Installed on the tundish 6, the diversion sleeve 8 and the observation window 10 are installed on the vacuum cover 4, the sliding nozzle mechanism 7, the diversion sleeve 8 and several steel ingot molds 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com