Wear-resistant bainite cast steel liner plate and its manufacture process

A manufacturing method and bainite technology, applied in manufacturing tools, casting molding equipment, molding machines, etc., can solve the problems of easy environmental pollution, unstable quality and high production cost of quenching medium, and improve the performance of the lining plate and the production process. Simple and easy, the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

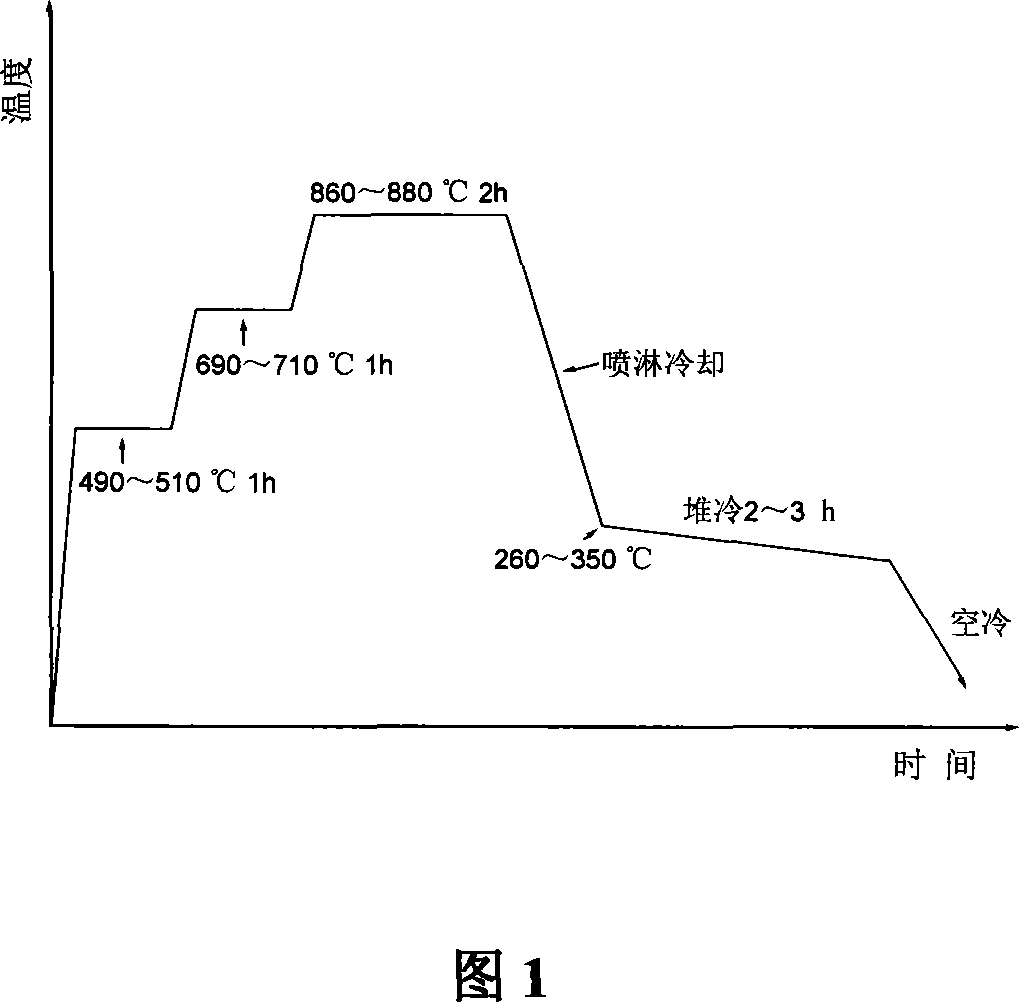

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The composition mass ratio (wt.%) of cast steel liner plate in the present invention is: C: 0.45~0.55%; Si: 1.6~2.0%; Mn: 2.8~3.3%; P≤0.06%; S≤0.04%; The amount is Fe.

[0026]

Assay composition (wt.%)

C

Si

mn

Example 1

Example 2

Example 3

Example 4

0.43

0.47

0.44

0.48

1.86

1.92

1.98

1.87

3.28

2.98

3.11

2.92

[0027] (1) The melted molten steel is cast into shape according to the following method: vacuum solid mold casting (EPC). Specifically: first bond the lining boards into strings, then apply a 1mm thick quartz sand bentonite paste paint, and bake at 60°C for 4 hours; when modeling, first place the sand box on the vibration table, Fill in the bottom sand, after vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com